METROM’s

Blog

METROM’s

Blog

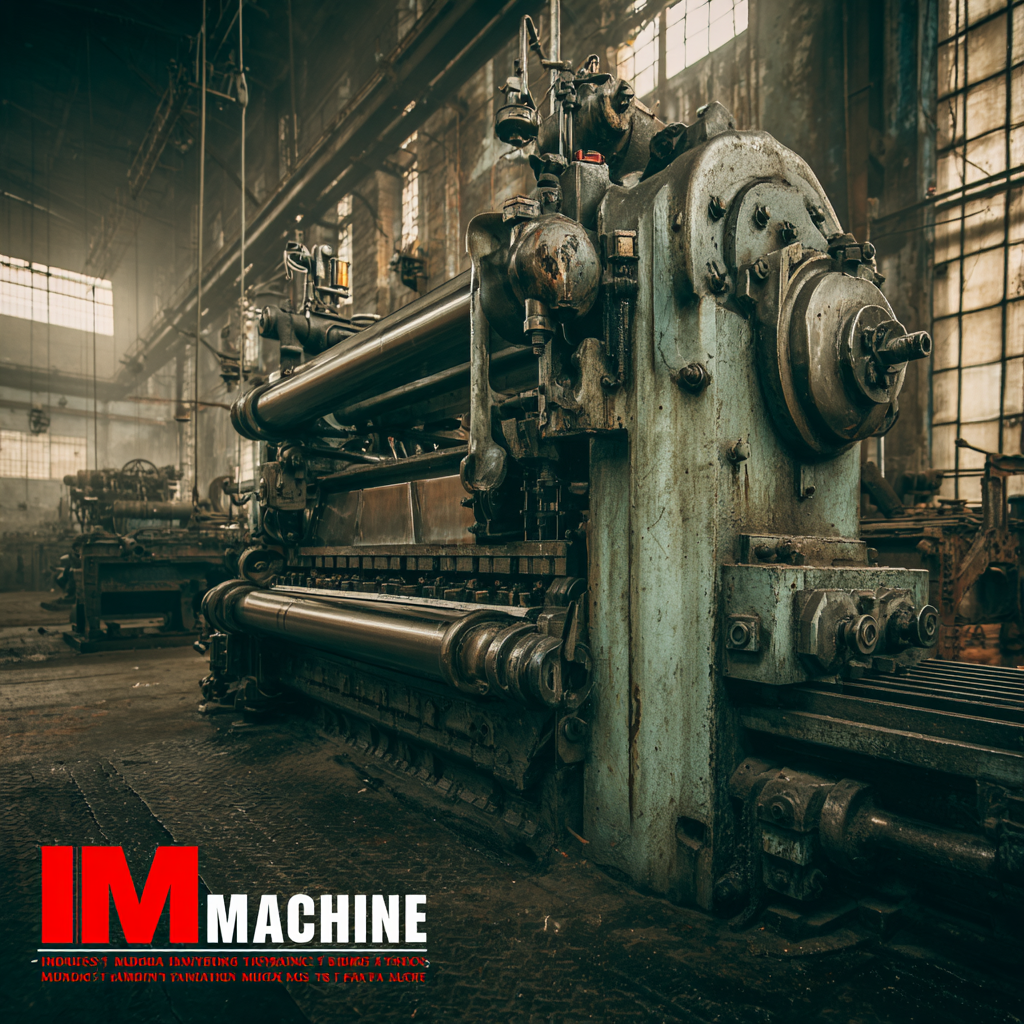

5 Unexpected Reasons Why You Need the Best Industrial Machine Today

As we advance towards 2025, the landscape of industrial machinery is evolving rapidly, driven by technological innovations and market demands. According to a report by McKinsey, the global industrial automation market is projected to reach $296 billion by 2026, underscoring the critical role of cutting-edge industrial machines in enhancing productivity and efficiency. In this dynamic environment, businesses must recognize the unexpected reasons why investing in the best industrial machines today is not just beneficial but essential. From optimizing supply chain dynamics to integrating AI-driven solutions for improved operational performance, the right industrial machine can dramatically influence a company's competitive edge. This blog will explore five unexpected yet compelling reasons that highlight the urgency and importance of securing top-tier industrial machines in your operations today.

The Rise of Automation: Driving Efficiency in Industrial Processes

The rise of automation is revolutionizing industrial processes, significantly enhancing efficiency and environmental sustainability. As organizations grapple with climate change and resource scarcity, there is an urgent need to adopt smarter, energy-efficient systems powered by artificial intelligence (AI). A recent report projects the industrial control systems market will continue to expand, driven by advancements in technologies such as SCADA, DCS, and PLC, targeting applications across various sectors including power and manufacturing.

China has emerged as the world’s largest market for industrial robots, maintaining its position for 11 consecutive years. This growth reflects the increasing density of industrial robots globally and highlights the shift towards automation as a critical driver of industrial efficiency. With the advent of Industry 4.0, manufacturing is now seamlessly integrating advanced digital technologies into its processes. This transformation not only maximizes operational accuracy and consistency but also empowers companies to focus on sustainability, ultimately reducing their environmental impact while meeting rising demand.

Impact of Automation on Industrial Efficiency

This chart illustrates the percentage improvement in efficiency across various industrial processes due to the rise of automation. The data reflects the transformation seen in manufacturing, logistics, and quality control from 2018 to 2023.

Harnessing Big Data: Transforming Decision-Making in Manufacturing

In today's manufacturing landscape, harnessing big data has become a game-changer for decision-making processes. With the advent of advanced analytics tools, companies can now collect and analyze vast amounts of data in real-time. This capability allows businesses to identify patterns, predict outcomes, and make informed choices that enhance operational efficiency. For instance, by understanding equipment performance and maintenance needs through data analysis, manufacturers can reduce downtime and improve production schedules.

Moreover, the integration of big data into industrial processes fosters smarter resource allocation. By analyzing historical data trends, manufacturers can optimize their supply chains, adjust their inventory levels, and better forecast market demands. This approach not only minimizes waste but also ensures that companies remain competitive in a rapidly evolving market. As organizations strive to achieve operational excellence, embracing big data is not just an option; it's a necessity that transforms how decisions are made, driving profitability and innovation in the industry.

Sustainable Solutions: The Shift Towards Eco-Friendly Industrial Machines

The industrial landscape is evolving rapidly, and one of the most significant shifts we are witnessing is the move towards eco-friendly machines. As global concerns around climate change and sustainability intensify, industries are recognizing the urgent need to adopt sustainable solutions. Investing in the best industrial machines today is not just about efficiency and productivity; it’s also about embracing technology that minimizes environmental impact.

Modern industrial machines are designed with energy efficiency in mind, significantly reducing power consumption and minimizing waste. With innovations like advanced materials and smarter production processes, these machines offer a dual benefit: enhancing operational performance while decreasing the carbon footprint. This shift towards eco-friendly machinery not only aligns with corporate social responsibility goals but also appeals to a growing base of environmentally-conscious consumers who prioritize sustainability in their purchasing decisions.

Moreover, adopting sustainable industrial machines can lead to long-term cost savings. While the initial investment might be higher, the reduction in energy usage, maintenance costs, and potential fines for non-compliance with environmental regulations can outweigh the initial expenditures. By prioritizing eco-friendly solutions, industries position themselves as forward-thinking leaders in their respective markets while contributing positively to the planet.

5 Unexpected Reasons Why You Need the Best Industrial Machine Today - Sustainable Solutions: The Shift Towards Eco-Friendly Industrial Machines

| Reason | Impact on Sustainability | Long-term Cost Savings | Operational Efficiency | Technological Advancements | Regulatory Compliance |

|---|---|---|---|---|---|

| Enhanced Energy Efficiency | Reduces greenhouse gas emissions | Lower energy bills over time | Increases overall throughput | Integration of smart technology | Meets new eco-regulations |

| Reduction in Material Waste | Minimizes landfill contributions | Fewer raw materials needed | Improved resource allocation | Utilization of recycled materials | Aligns with circular economy principles |

| Improved Product Quality | Less defective products, less waste | Reduces costs of returns and replacements | Enhances customer satisfaction | Adoption of precise manufacturing techniques | Facilitates compliance with quality standards |

| Incorporation of Automation | Lowers human error rates | Reduces labor costs | Enhances speed and consistency | Access to advanced technologies | Supports labor law compliance |

| Availability of Customization | Promotes tailored solutions for eco-needs | Increases market competitiveness | More adaptable production processes | Tailored applications in various industries | Enhances compliance adaptability |

Adaptability in Production: Meeting Customization Demands with Advanced Machinery

In today's fast-paced manufacturing landscape, adaptability has emerged as a crucial factor for success. As businesses strive to meet the increasing demands for customization, advanced industrial machinery plays a pivotal role in facilitating this transformation. The integration of smart reconfigurable machines allows production lines to swiftly adjust to varying product specifications without significant downtime or resource wastage. This enables manufacturers to offer a wider range of products while maintaining efficiency and quality.

Moreover, the production volume versus variety concept illustrates how modern machinery can balance high output with diverse product offerings. By leveraging Industry 4.0 technologies, manufacturers can seamlessly reconfigure their machines to handle different tasks. This flexibility not only satisfies customer preferences but also enhances competitiveness in a market characterized by rapid changes.

Investing in the best industrial machines today is thus not merely a choice; it is a strategic necessity that empowers businesses to thrive by meeting the evolving demands of their customers.

Cost-Benefit Analysis: Investing in High-Quality Machines for Long-Term Savings

When considering the acquisition of industrial machines, performing a thorough cost-benefit analysis is essential. Investing in high-quality machines, while often more expensive upfront, can lead to significant long-term savings. For instance, advanced machinery is typically designed for efficiency, reducing energy consumption and operational costs over time. The superior build quality of these machines also translates into lower maintenance expenses and fewer breakdowns, which can be disruptive and costly.

Additionally, productivity gains from utilizing top-tier machines can significantly enhance operational output. High-quality machines often come equipped with the latest technology, allowing for faster production times and more precise manufacturing processes. This efficiency not only boosts the bottom line but also offers a competitive edge in the marketplace. Therefore, when evaluating potential purchases, it’s critical to look beyond initial prices and consider how an investment in the best industrial machines can yield substantial returns, both financially and operationally.