METROM’s

Blog

METROM’s

Blog

The Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine in 2025

In the rapidly evolving world of manufacturing, the importance of precision and versatility in machining cannot be overstated. As we approach 2025, the demand for advanced machinery has led to a surge in the popularity of the *5 axis CNC milling machine*. Renowned industry expert Dr. Emily Carter, a leading authority in CNC technology, asserts, “The integration of five-axis machining not only enhances productivity but dramatically expands the creative possibilities for design engineers.” Her insights highlight the transformative potential of these machines in various sectors, from aerospace to automotive manufacturing.

Choosing the right *5 axis CNC milling machine* can significantly impact operational efficiency and product quality. With an influx of options available in the market, navigating this landscape requires a thorough understanding of the key features and specifications that delineate superior machines from the rest. As manufacturers strive to remain competitive, investing in cutting-edge technology becomes critical, and five-axis solutions offer unparalleled flexibility and precision, allowing for complex geometries and intricate designs that traditional milling cannot achieve.

In the sections that follow, we will delve into essential criteria for selecting the best *5 axis CNC milling machine* for your needs in 2025, providing a comprehensive overview of factors such as machine construction, software capabilities, and cost-effectiveness, ensuring you make an informed decision that will propel your manufacturing capabilities into the future.

Understanding 5 Axis CNC Milling Machines: Key Principles and Benefits

5 Axis CNC milling machines are essential tools in modern manufacturing, offering unparalleled precision and versatility. Unlike traditional 3-axis machines, these advanced systems can move along five different axes, allowing for intricate designs and complex geometries to be machined in a single setup. This capability significantly reduces the need for multiple setups and minimizes the risk of errors, ensuring that high-quality components are produced with greater efficiency.

One of the primary benefits of 5 Axis machining is its ability to process complex parts with extreme accuracy. By having the spindle able to tilt and rotate, operators can reach difficult angles and features that would be impossible with standard milling machines. This leads to shorter production times and reduced material waste, as parts can often be completed without additional fixtures.

Additionally, 5 Axis CNC machines can enhance surface finish and dimensional accuracy, making them ideal for industries that demand precision, such as aerospace and medical device manufacturing. Understanding these principles and benefits can guide manufacturers in making informed choices about their machining processes in the near future.

Identifying Your Needs: Factors to Consider Before Choosing a Machine

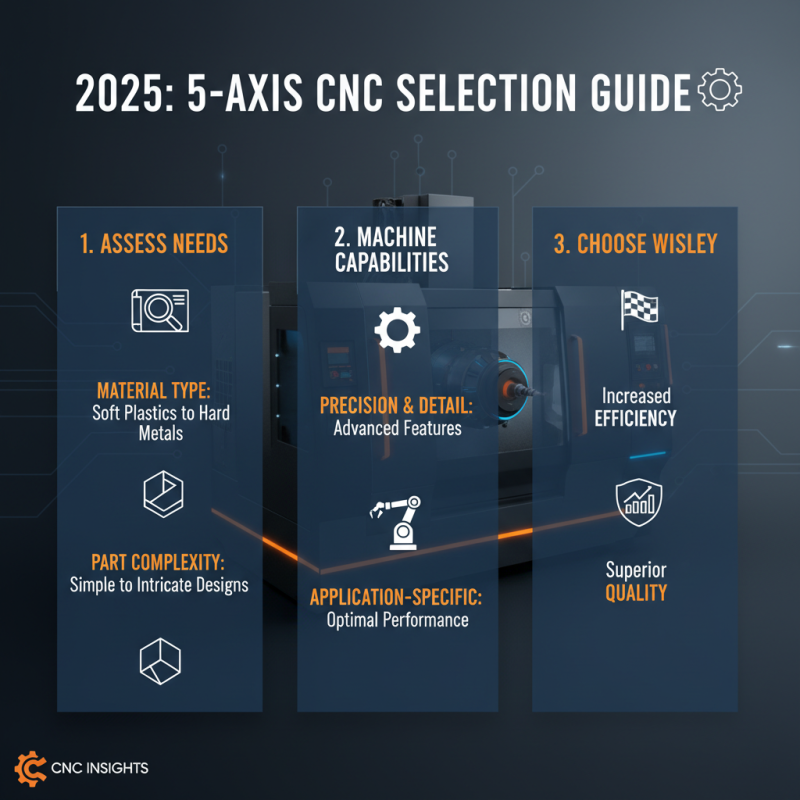

When selecting the best 5-axis CNC milling machine in 2025, the first step is to thoroughly assess your specific needs. Start by evaluating the types of materials you will be working with. Different machines excel in machining various materials, from soft plastics to hard metals, and it's important to choose a machine that can handle your specific applications effectively. Additionally, consider the complexity of the parts you plan to produce. If intricate designs are common in your projects, investing in a machine with advanced capabilities will yield better precision and detail.

Another critical factor to weigh is the machine's size and workspace. Analyze the dimensions of the components you'll be machining and ensure the milling machine can accommodate them without limitations. The available space in your workshop also plays a significant role, as you want a machine that fits comfortably while allowing for safe operation and maintenance. Furthermore, evaluate the machine's software and ease of use; user-friendly interfaces can significantly reduce training time for operators and improve overall productivity.

Top Features to Look for in a 5 Axis CNC Milling Machine

When selecting the best 5 axis CNC milling machine for your needs in 2025, it is essential to focus on the top features that can enhance productivity and precision. First and foremost, look for a machine that offers advanced control systems. These systems allow for smoother operation and improved accuracy when handling complex geometries. A user-friendly interface also plays a crucial role, enabling operators to easily navigate through programs and settings without significant downtime or learning curves.

Another critical feature is the machine's rigidity and stability. A robust frame and high-quality components minimize vibrations, ensuring that the milling process remains consistent and precise. Additionally, consider the machine's versatility; the ability to handle various materials such as metals, plastics, and composites can greatly expand its usefulness in different industries. Lastly, support for cutting-edge toolpath strategies and the integration of automation can significantly enhance workflow efficiency, making the milling process faster and less labor-intensive.

Comparing Leading Brands and Models for 2025

When navigating the ever-evolving landscape of 5-axis CNC milling machines in 2025, it’s crucial to understand the nuances across leading brands and models. Industry reports indicate that the global CNC milling machine market is projected to reach $100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is driven by advancements in technology and increased demand for precision manufacturing across various sectors, including aerospace, automotive, and healthcare.

When comparing models, consider the critical features such as spindle speed, dynamic stiffness, and the machine's ability to perform complex geometries. For instance, machines equipped with advanced digital controls not only enhance productivity but also improve accuracy, which is a significant demand in precision industries. According to a recent study, companies that upgraded to 5-axis machines reported a 30% reduction in manufacturing time, emphasizing the efficiency gains these models can provide.

Tips: Before making a decision, assess your specific manufacturing needs and the materials you will be working with. Also, consider investing in training for your team to maximize the machine’s capabilities. This investment in skills can result in optimal machine utilization, ensuring a robust return on investment.

Budgeting and Investment Strategies for a 5 Axis CNC Machine

When investing in a 5 Axis CNC milling machine, careful budgeting is crucial to ensure that you make a sound decision. Begin by assessing your needs—consider the types of projects you'll be tackling and the complexity of the parts you need to produce. This evaluation will help you determine the specifications and features that are essential for your operations. Additionally, factor in not only the initial purchase price but also the costs associated with maintenance, tooling, and training.

Tip: Always set aside a portion of your budget for unexpected expenses. Machines often require calibration or additional tooling, which can add to your costs post-purchase.

It's also beneficial to explore financing options available for such substantial investments. Leasing a machine can be an attractive way to manage cash flow, allowing businesses to keep their resources flexible while accessing the latest technology. Furthermore, consider the long-term savings of investing in a high-quality machine: a reliable CNC mill can enhance productivity, reduce waste, and ultimately lead to better profit margins.

Tip: Research potential tax incentives or grants that can assist in offsetting costs, as government programs may support businesses that invest in advanced manufacturing technologies.

Related Posts

-

The Future of Precision Manufacturing: Advancements in CNC Milling Machines

-

How to Optimize Efficiency with CNC Industrial Machines for Your Business

-

What is an Industrial CNC Milling Machine and How Does It Work?

-

Unwavering Quality and Reliability of China's Best Precision CNC Milling Machines for Global Buyers

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business