METROM’s

Blog

METROM’s

Blog

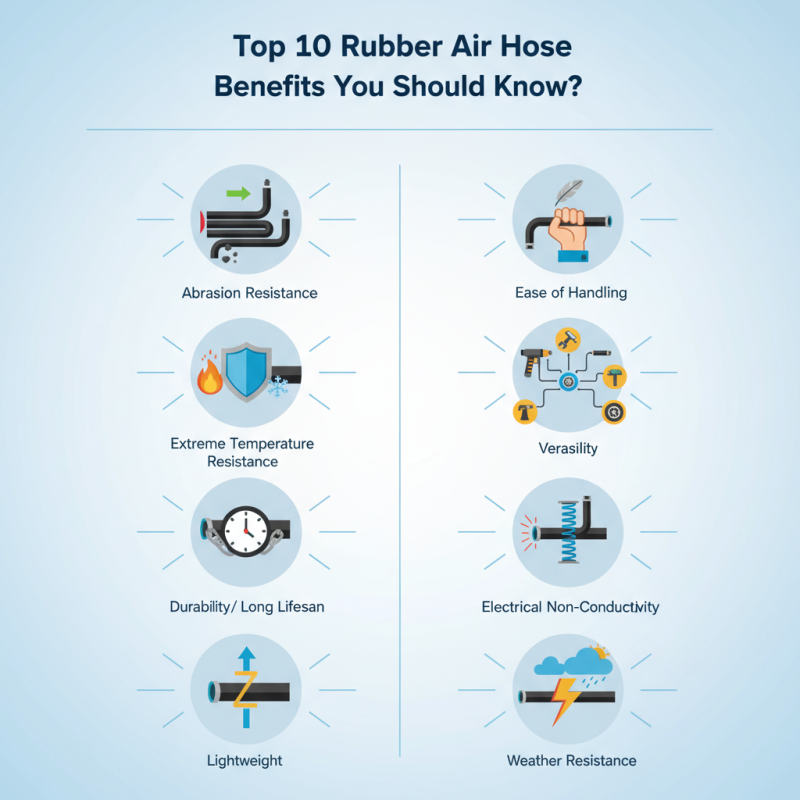

Top 10 Rubber Air Hose Benefits You Should Know?

When it comes to tools and equipment, a rubber air hose stands out. This essential item plays a significant role in various industries. Understanding the benefits of rubber air hoses can help users make informed choices.

One major advantage is flexibility. rubber air hoses can bend without kinking. This makes them perfect for tight spaces. They also resist abrasions and extreme temperatures. With proper care, they last longer than many alternatives. However, some users may overlook these features.

Another key benefit is their lightweight nature. This makes handling easier. Workers can move them without much effort. Yet, some still choose heavier options. This might not be the best choice for efficiency. Recognizing these aspects can lead to more effective usage of rubber air hoses in everyday applications.

Key Advantages of Using Rubber Air Hoses in Various Applications

Rubber air hoses are widely used in various applications due to their numerous advantages. They are known for their durability and flexibility. This makes them perfect for both indoor and outdoor use. Unlike some other materials, rubber can withstand extreme temperatures. This property ensures they perform well in hot and cold environments. Additionally, rubber hoses are resistant to wear and tear, enhancing their lifespan.

Another benefit is that rubber air hoses offer excellent air flow. They allow for efficient air transfer, which is crucial in industrial settings. The smooth interior reduces friction, making it easier for air to flow through. Another tangible advantage is their ability to resist kinks and twists. This feature prevents interruptions during operation, which can be frustrating. Moreover, rubber hoses are generally lighter than some alternatives, aiding in easy handling.

However, it’s worth considering that rubber hoses can be less resistant to certain chemicals. This may limit their use in specific applications. Although innovative, they can sometimes take longer to expand or retract due to their material properties. Users should reflect on these limitations to ensure they are choosing the right equipment for their needs. In some cases, a thorough evaluation of the environment helps in making a better selection.

Durability and Flexibility: Why Rubber Hoses Outperform Other Materials

Rubber air hoses are renowned for their durability and flexibility. Unlike hoses made from other materials, rubber can withstand extreme conditions. These hoses resist abrasion and can endure high pressures. They are ideal in varying temperatures, from scorching heat to freezing cold. Many users appreciate how rubber maintains its performance over time. This longevity is crucial in demanding work environments.

When comparing rubber hoses to others, flexibility is another significant advantage. Rubber remains pliable, allowing for easier handling. It can twist and turn without kinking. For those working in tight spaces, this is a game changer. However, not all rubber hoses are created equal. Some may deteriorate faster than others if not maintained properly. Users should regularly inspect their hoses for wear.

It's important to be mindful of how you use rubber hoses. They can provide excellent service, but neglect can lead to problems. Lack of cleaning may cause buildup, affecting performance. Proper care can enhance their lifespan. Recognizing both the strengths and weaknesses helps maximize the benefits of rubber air hoses.

Resistance to Temperature Extremes and Environmental Conditions

Rubber air hoses offer remarkable resistance to temperature extremes. They can perform well in very cold or hot conditions. Studies show that quality rubber hoses can endure temperatures as low as -40°F and as high as 190°F. This temperature resilience ensures they remain functional in diverse environments.

In addition to temperature, rubber air hoses resist various environmental conditions. They withstand UV rays, oil, and water exposure better than many alternatives. Interestingly, research indicates that rubber hoses maintain their durability and flexibility more effectively than plastic counterparts. However, some users overlook the necessity of proper storage to extend hose life. Improper handling can lead to cracks, reducing effectiveness.

Choosing the right rubber hose matters, but it isn't always straightforward. Many consumers may not notice early signs of wear. The industry suggests performing regular inspections to catch these issues. Understanding environmental limitations can significantly enhance performance and longevity. Balancing performance and maintenance helps ensure optimal usage in challenging conditions.

Lightweight Design: Enhancing Portability and Ease of Use

When looking for hoses, lightweight design is a game changer. It allows for easy handling. A rubber air hose, being lighter, improves portability significantly. You can carry it around without straining your back. This feature is great for both home and professional use. You need to consider the location of your work—sometimes, heavy hoses become a burden.

Additionally, the flexibility of these lightweight hoses is remarkable. Maneuvering them in tight spaces is much easier. You can bend and twist them without much effort. However, while they are easier to use, the lighter material can be less durable in some cases. Users might find the need to replace them more often. It’s important to balance weight and durability in your choice.

When you want to store your hoses, the lightweight design helps. You can roll them up without much trouble. This saves space in your garage or workspace. Keep in mind that a lighter hose doesn't always mean lower quality. It's essential to check the specifications. If you overlook this, you might end up with a product that doesn't last as long as expected.

Top 10 Benefits of Rubber Air Hoses

Versatile Applications: From DIY Projects to Professional Industries

Rubber air hoses offer unique advantages in various fields. In DIY projects, the flexibility and durability of these hoses make them ideal for connecting air tools and compressors. Their lightweight nature allows for easy maneuverability. According to the North American Industrial Classification System (NAICS), industries such as construction and automotive rely heavily on pneumatic tools. Here, rubber air hoses are essential for delivering consistent compressed air.

In professional settings, rubber air hoses are pivotal in manufacturing. They withstand extreme temperatures and resist wear and tear. A study by the Industrial Supply Association reported that manufacturers using high-quality hoses improve their efficiency by 25%. This efficiency boost comes from reduced downtime caused by leaks or equipment failure. However, there are concerns. Some rubber hoses may degrade more quickly in harsh environmental conditions, leading to failures. Understanding these pitfalls is crucial for selecting the right hose for specific applications.

Top 10 Rubber Air Hose Benefits You Should Know

| Benefit | Description | Applications |

|---|---|---|

| Durability | Resistant to wear and tears, ensuring long-lasting performance. | Construction, Manufacturing |

| Flexibility | Easily bends without kinking, allowing for smooth operation. | DIY Projects, Auto Repairs |

| Weather Resistance | Remains functional in varying temperatures and weather conditions. | Outdoor Work, Agricultural Uses |

| Lightweight | Easy to handle and transport without sacrificing quality. | Home Use, Portable Compressors |

| Chemical Resistance | Maintains integrity when in contact with various chemicals. | Industrial Settings, Cleaning Applications |

| Cost-Effective | Affordable solution for various air supply needs. | Small Workshops, Homeowners |

| Flow Efficiency | Ensures consistent air flow for optimal performance. | HVAC Systems, Pneumatic Tools |

| Easy Storage | Can be coiled easily, saving space during storage. | Mobile Workshops, Storage Facilities |

| Versatility | Suitable for a variety of tools and applications. | Various Industries, Residential Projects |