METROM’s

Blog

METROM’s

Blog

Top CNC Milling Machines: How to Choose the Best for Your Needs

In the ever-evolving world of manufacturing, selecting the right CNC machine milling machine is crucial for achieving precision and efficiency. According to industry expert Dr. Emily Carter, a leading figure in CNC technology, “The right milling machine can transform the capabilities of a workshop, allowing for intricate designs and precise tolerances that were once thought impossible.” Understanding the different features, capabilities, and specifications of these machines is key to making an informed decision that aligns with your production needs.

As the demand for high-quality machined parts increases, the CNC machine milling machine has become a staple in manufacturing processes across various sectors. With advancements in technology, these machines now offer enhanced functionalities such as multi-axis operations and automation, making it easier for manufacturers to streamline workflows and improve output quality. When selecting a CNC milling machine, it’s essential to consider factors such as the type of materials you will be working with, the complexity of the parts to be produced, and your budget constraints.

Navigating through the myriad options available in the market can be overwhelming, but understanding your specific requirements and conducting thorough research will ultimately lead to the best investment for your needs. Whether you are a small business owner or part of a large manufacturing operation, choosing the right CNC machine milling machine is pivotal for staying competitive and meeting the demands of your clients.

Understanding CNC Milling Machines: Basics and Types

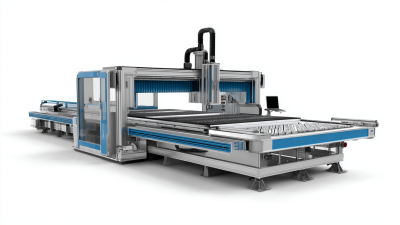

CNC milling machines are essential tools in modern manufacturing and machining processes, allowing for precise and automated material removal. Understanding the basics of these machines is crucial for selecting the right one for your specific needs. At their core, CNC (Computer Numerical Control) milling machines use computer technology to control the movement of cutting tools along multiple axes, typically two or three, although advanced models can operate in five axes or more. This capability enables intricate designs and complex shapes to be produced with high accuracy, making CNC milling machines invaluable in various industries, including aerospace, automotive, and healthcare.

In terms of types, CNC milling machines can be categorized broadly into vertical and horizontal models. Vertical CNC milling machines feature a spindle that is oriented vertically, allowing for the cutting tool to move up and down, which is ideal for creating slots and complex shapes. Horizontal CNC milling machines, on the other hand, have a horizontally oriented spindle, which provides better chip removal and is ideal for producing flat surfaces and complex contours. Additionally, there are specialized types, such as 5-axis machines, which allow for greater flexibility and can produce intricate parts with a single setup, reducing the need for workpiece repositioning. Understanding these types and their functions helps users to make informed choices tailored to their specific machining projects.

Key Features to Consider When Choosing a CNC Milling Machine

When selecting a CNC milling machine, understanding the key features is crucial to making an informed decision tailored to your specific needs. One of the foremost considerations is the machine's size and working capacity. Depending on the types of projects you plan to undertake, assess the longitudinal and vertical travel of the milling machine to ensure it can accommodate your workpieces. Additionally, consider the machine's table size, as this will impact your ability to work on larger components.

Another essential feature to evaluate is the spindle speed and power. Different materials require different cutting speeds, and a machine with a higher spindle speed will allow you to work with a wider range of materials efficiently. Moreover, the motor's power plays a significant role in the machine's ability to handle tough jobs and maintain performance under load. It is also important to look at the control system; a user-friendly interface can significantly enhance productivity and ease of operation, especially for those who may not be as familiar with CNC technology. Finally, assess the machine's rigidity and stability, as these factors critically influence accuracy and finish quality in your milling processes.

Top CNC Milling Machines: Key Features Comparison

Assessing Your specific Needs for CNC Milling Applications

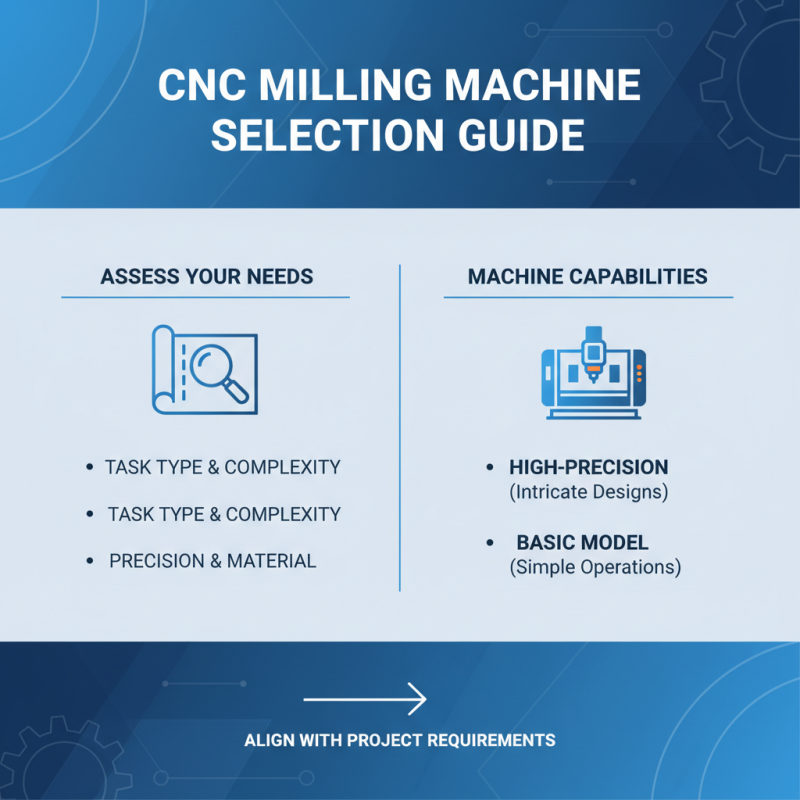

When selecting a CNC milling machine, a crucial step is to assess your specific needs based on the type and complexity of the tasks you intend to perform. Different CNC milling applications may require varying levels of precision, material compatibility, and dimensional capabilities. For instance, if your projects involve intricate designs and tight tolerances, a high-precision machine with advanced features may be essential. Conversely, for simpler operations, a more basic model might suffice, making it vital to align machine capabilities with your project requirements.

Additionally, consider the materials you will most frequently work with, as certain CNC milling machines are optimized for specific materials, such as metals, plastics, or wood. Understanding the properties of these materials—such as their machinability and the tooling required—will help inform your decision. Furthermore, assess the size and scale of your projects, as this will influence the bed size and capacity of the machine. Carefully evaluating these factors will enable you to choose a CNC milling machine that not only fits your current needs but also adapts to potential future demands in your production workflow.

Budget Considerations: Cost vs. Quality in CNC Milling Machines

When considering the purchase of a CNC milling machine, budget plays a crucial role in determining the right fit for your needs. According to industry reports, the price of CNC milling machines can range significantly, with entry-level models starting around $10,000 and advanced systems soaring above $100,000. This variance arises from factors such as build quality, precision, and additional features. It is essential to assess not only the upfront cost but also the long-term value the machinery will provide, including potential maintenance costs and operational efficiency.

Quality is equally important in this decision-making process. A lower price could lead to compromised durability and precision, which are critical in machining applications. A 2022 market analysis indicated that businesses investing in high-quality CNC machinery reported a 20-30% increase in productivity due to reduced downtime and higher accuracy. Therefore, while budget constraints are a reality for many operators, prioritizing quality can yield significant returns in efficiency and output, ultimately justifying the initial investment.

Balancing cost and quality requires careful consideration of individual project needs and operational capabilities to ensure that the selected CNC milling machine meets both financial and technical expectations.

Top Brands and Models of CNC Milling Machines to Explore

When it comes to choosing the best CNC milling machine for your needs, exploring top brands and models is essential. Various manufacturers offer a wide range of options tailored for different applications, from hobbyist projects to industrial-grade production. Consider the machine's specifications, such as spindle speed, feed rate, and the maximum cutting depth, as these will significantly influence your milling capabilities. Additionally, the size and weight of the machine may impact your workspace, so it's vital to assess your environment before making a decision.

In the market, you'll find several standout models that cater to distinct requirements. For example, some machines are designed specifically for precision machining, making them ideal for intricate designs and detailed components. Others focus on robustness and durability, suitable for heavy-duty jobs that demand consistent performance. User-friendly features like intuitive software interfaces and effective customer support can also enhance your overall experience, making it easier to master the complexities of CNC milling. By carefully evaluating these factors, you can identify the milling machine that best aligns with your specific needs and preferences.

Related Posts

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

Unlocking Precision: How CNC Milling Machines Drive Efficiency in Modern Manufacturing Industry

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

Exploring the Versatility and Innovations of CNC Machines in Modern Manufacturing

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers