METROM’s

Blog

METROM’s

Blog

Top CNC Machines to Watch in 2026 What Makes Them Stand Out?

As we look towards 2026, the realm of CNC machines is evolving rapidly. New models are emerging with advanced features and capabilities. These innovations promise to enhance precision, speed, and efficiency in manufacturing. Understanding the strengths of each CNC machine will be essential for potential buyers.

CNC technology has transformed industries. The best CNC machines now incorporate features like IoT connectivity and AI integration. These advancements facilitate real-time monitoring and predictive maintenance. However, with so many options, it can be challenging to identify standout models. Users must carefully consider their specific needs and applications.

In this ever-changing landscape, one might question the pace of innovation. Are the latest features truly beneficial, or just marketing jargon? Some machines may not deliver on their promises. Thus, it's crucial to weigh the benefits against potential drawbacks before making a commitment.

Emerging Trends in CNC Machine Technology for 2026

As we approach 2026, CNC machine technology is evolving rapidly. One key trend is the rise of automation. These machines are becoming more autonomous. This means less manual intervention. Workers can focus on higher-value tasks. In factories, the atmosphere is changing. Automation has both advantages and challenges.

Another emerging trend is the integration of AI. Smart CNC machines can learn from data. They improve their performance over time. This technology increases efficiency but may create a skill gap. Operators need training to manage these advanced systems. Not everyone is ready for this shift. There are concerns about job displacement, too.

Sustainability is also on the radar. Machines are being designed for energy efficiency. This reflects a growing awareness of environmental impacts. However, the road to fully green operations is not straightforward. Some technologies still depend on non-renewable resources. Balancing innovation with sustainability will be crucial for future progress.

Key Features of the Most Anticipated CNC Machines

CNC machines are rapidly evolving. By 2026, several models are expected to stand out. These machines will not only improve productivity but also enhance precision. Reports suggest the global CNC machine market will reach $77 billion by 2026. This growth reflects the demand for automation and efficiency across industries.

Key features to watch for include advanced sensor technologies. These sensors can monitor machining processes in real-time. They provide feedback for adjustments, improving accuracy. Signals indicate when maintenance is needed, preventing costly downtime. Automation will likely drive accuracy levels above 99%, which is crucial for manufacturers.

Tips for buyers: evaluate the ease of integration with existing systems. Also, consider machines with user-friendly interfaces. This can significantly reduce training time. While newer machines often have impressive specs, cost-effectiveness must be a priority. Reflect on total ownership costs, not just the initial outlay. Prioritize reliability and maintenance support. A machine that is hard to service can lead to unexpected expenses.

Top CNC Machines to Watch in 2026 - Key Features Comparison

Leading Brands Dominating the CNC Market in 2026

The CNC market in 2026 is expected to showcase remarkable innovations from leading brands. These companies focus on precision and versatility. A key characteristic is adaptability to various materials, enhancing production capabilities significantly. Users will find machines that cater to both small-scale and large-scale operations. Compact designs will suit limited workspace, while larger models can tackle heavy-duty tasks.

Another distinctive feature is automation. Increased integration of AI technologies will streamline operations. This trend provides a user-friendly experience, enabling even novices to operate complex machinery. Enhanced safety measures will also be a focal point. Machines equipped with smart sensors can detect errors in real-time. This proactive approach minimizes downtime and reduces waste.

Despite the advancements, challenges remain. Not all users may fully understand new technologies. Training and support will become crucial. Additionally, the high initial investment may deter some smaller businesses. Balancing cost with technology will require careful consideration. As manufacturers innovate, it will be important to ensure accessibility for all potential users.

Comparative Analysis: Traditional vs. Innovative CNC Machines

The landscape of CNC machining is evolving. Traditional CNC machines have set standards for precision and reliability. However, innovative CNC machines are introducing features that can reshape industries. A recent report indicates a projected market growth of 7.2% for advanced CNC technologies by 2026. This shift reflects the demand for efficiency and customization.

Traditional machines primarily focus on basic functionalities. They are robust but less adaptable. For instance, they require manual setups, which can prolong production times. In contrast, innovative machines offer user-friendly interfaces and automation. This reduces the learning curve and supports complex designs. More than 60% of manufacturers cite flexibility as a key benefit of evolving CNC technologies.

Yet, this transition is not without challenges. Innovative machines can demand higher initial investments. Some manufacturers are hesitant due to budget constraints. Additionally, staff training is essential for maximizing these technologies. Industry experts emphasize the importance of balancing investment with skill development. The future of CNC machining will rely on how effectively companies navigate these dual demands.

Top CNC Machines to Watch in 2026 - Comparative Analysis: Traditional vs. Innovative CNC Machines

| Machine Type | Processing Speed (m/min) | Accuracy (mm) | Versatility | Cost Efficiency |

|---|---|---|---|---|

| Traditional CNC Mill | 15 | 0.05 | Medium | Moderate |

| Innovative CNC Laser Cutter | 30 | 0.01 | High | High |

| Traditional CNC Lathe | 20 | 0.02 | Low | Low |

| Innovative CNC 3D Printer | 25 | 0.1 | Very High | Moderate |

| Innovative CNC Waterjet Cutter | 35 | 0.05 | High | High |

Applications of CNC Machines Across Various Industries in 2026

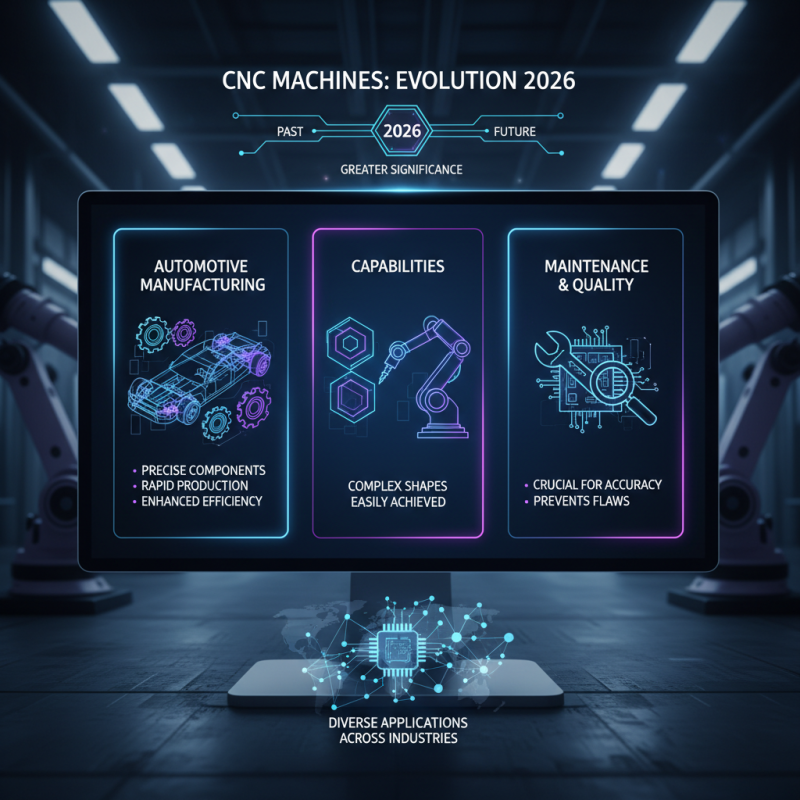

CNC machines are evolving rapidly, with diverse applications across industries. In 2026, their significance will be even greater. Automotive manufacturing is one sector where CNC technology shines. These machines create precise components quickly, enhancing production efficiency. Complex shapes are easily achieved, but flaws can occur. Regular maintenance is crucial to avoid errors.

The aerospace industry also benefits immensely from CNC machines. They help in crafting intricate parts that must meet strict safety standards. These machines offer precision that manual methods struggle to match. However, they require skilled operators who understand their capabilities and limitations.

In the medical sector, CNC machines produce custom implants and devices. Tailored solutions improve patient outcomes. Yet, the technology must adapt constantly, as regulations can change. Striking a balance between innovation and compliance remains challenging for many.

Related Posts

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

Top CNC Milling Machines: How to Choose the Best for Your Needs

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

Unlocking Precision: How CNC Milling Machines Drive Efficiency in Modern Manufacturing Industry

-

Exploring the Versatility and Innovations of CNC Machines in Modern Manufacturing