METROM’s

Blog

METROM’s

Blog

2025 Top CNC Industrial Machine Trends You Need to Know

In the rapidly evolving landscape of manufacturing, the CNC industrial machine sector is continuously pushing boundaries and adapting to new technologies. As we look towards 2025, industry experts, such as Dr. Emily Hargrove, a renowned specialist in automation and manufacturing technologies, emphasize the transformative nature of these machines. "The future of CNC industrial machines lies in their ability to integrate advanced software and AI, enabling unprecedented levels of precision and efficiency," she noted during a recent seminar.

As companies strive to remain competitive, understanding the trends that will shape CNC industrial machines in the upcoming years becomes essential. From the emergence of smart manufacturing solutions to the integration of sustainable practices, these trends are not just shaping the machines themselves, but also the entire industrial ecosystem surrounding them. The push for greater automation and data-driven decision-making highlights a significant shift towards a more connected and intelligent manufacturing process.

Keeping abreast of these trends is crucial for industry professionals and stakeholders alike. The year 2025 promises to bring about significant advancements that can redefine productivity and operational excellence, making it imperative for businesses to adapt and evolve with the growing capabilities of CNC industrial machines.

Emerging Technologies Influencing CNC Machine Design and Functionality

The landscape of CNC machine technology is rapidly evolving, driven by an array of emerging technologies that are reshaping design and functionality. According to a recent industry report from MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2025, fueled by advancements in automation, artificial intelligence (AI), and additive manufacturing. These technologies are not just enhancing precision and efficiency; they are also enabling new levels of customization that meet the demands of an increasingly diverse manufacturing environment.

One of the most significant trends is the integration of AI and machine learning within CNC systems. These advancements allow machines to learn from past operations and optimize performance in real-time, thus reducing waste and downtime. A study by McKinsey indicates that adopting AI in manufacturing could increase productivity by up to 20%. Furthermore, the incorporation of IoT devices enhances machine connectivity, allowing for better monitoring and predictive maintenance, which significantly extends equipment lifespan and reliability. This interconnected approach is leading to smarter factories where CNC machines can communicate with each other and adapt to production needs efficiently.

Additive manufacturing techniques are also gaining traction within CNC applications, providing manufacturers with unprecedented flexibility. By integrating subtractive and additive processes, manufacturers can produce complex geometries that were previously impossible or cost-prohibitive. The Wohlers Report notes that the additive manufacturing industry is anticipated to grow to $35.6 billion by 2024, reflecting how traditional CNC processes are adapting to incorporate innovative techniques. As these technologies continue to influence CNC machine design, manufacturers must stay abreast of these trends to remain competitive in the rapidly evolving industrial landscape.

2025 CNC Industrial Machine Trends

This bar chart illustrates the key emerging technologies influencing CNC machine design and functionality in 2025. The data represents the percentage of industry professionals who expect these technologies to significantly impact CNC machinery over the next few years.

Advancements in Automation and Robotics for CNC Industrial Machines

The integration of automation and robotics in CNC (Computer Numerical Control) industrial machines is transforming the manufacturing landscape at an unprecedented pace. As industries strive for higher efficiency and precision, advancements in robotics technology are enabling machines to perform complex tasks with minimal human intervention. Automation systems are being designed to enhance productivity by streamlining operational processes, allowing for real-time data analysis, and reducing downtime through predictive maintenance.

Moreover, the collaboration between CNC machines and robotic systems paves the way for greater flexibility in production lines. For instance, robotic arms can efficiently handle material loading and unloading, perform intricate assembly tasks, and even carry out quality inspections. The synergy between these technologies not only increases throughput but also minimizes human error, resulting in superior product quality. As we look towards 2025, the shift towards smarter, more interconnected manufacturing environments is expected to accelerate, driven by the continual evolution of automation and robotics in CNC applications.

2025 Top CNC Industrial Machine Trends You Need to Know

| Trend | Description | Impact | Expected Adoption Rate (2025) |

|---|---|---|---|

| Increased Automation | Enhanced use of automated machinery for precision in manufacturing processes. | Improved efficiency and reduced labor costs. | 70% |

| Robotics Integration | Deployment of collaborative robots to work alongside human operators. | Increased productivity and flexibility in manufacturing lines. | 65% |

| Advanced AI Algorithms | Utilization of AI for predictive maintenance and optimization of machining processes. | Reduced downtime and operational costs. | 60% |

| IoT Connectivity | Integration of Internet of Things (IoT) devices for real-time monitoring and data collection. | Enhanced decision making and resource management. | 75% |

| Sustainable Manufacturing | Focus on eco-friendly materials and energy-efficient machines. | Improved sustainability and compliance with regulations. | 55% |

Sustainability and Energy Efficiency Trends in CNC Manufacturing

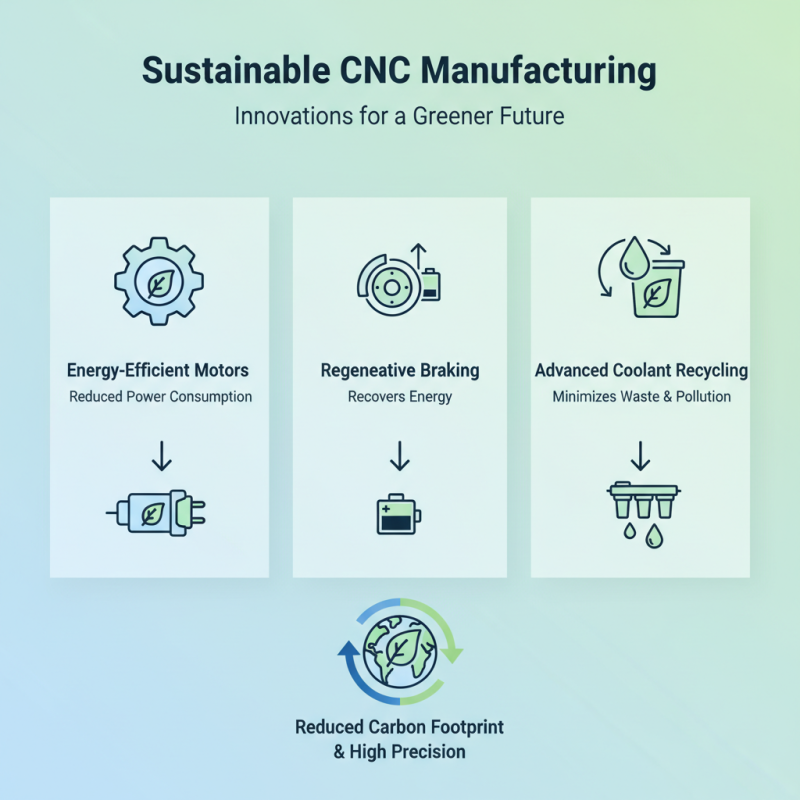

As CNC manufacturing continues to evolve, sustainability and energy efficiency have become paramount. The industry is witnessing a shift towards machines that not only deliver high precision but also minimize environmental impact. Innovations such as energy-efficient motors, regenerative braking systems, and advanced coolant recycling processes are transforming traditional CNC machining practices, allowing manufacturers to reduce their carbon footprint while maintaining productivity.

One effective strategy to enhance sustainability in CNC manufacturing is implementing predictive maintenance. By utilizing advanced monitoring systems, businesses can anticipate equipment failures before they occur, significantly reducing waste and downtime. This proactive approach not only conserves resources but also maximizes machine efficiency.

Additionally, adopting a circular economy model can further promote sustainability. This concept encourages the recycling of materials used in CNC operations and reusing components whenever possible. By designing machines that facilitate easy disassembly and repair, manufacturers can extend the lifespan of their equipment and decrease the amount of waste generated. Keeping these practices in mind will help companies stay ahead in the evolving landscape of CNC manufacturing.

Smart Manufacturing: The Rise of IoT in CNC Operations

The integration of the Internet of Things (IoT) in CNC operations marks a transformative leap in smart manufacturing. As per recent industry reports, the global IoT in manufacturing market is projected to reach USD 300 billion by 2026, showcasing a robust CAGR of 23%. This trend indicates that manufacturers are increasingly recognizing the potential of connected devices in optimizing production efficiencies and reducing downtime. By incorporating IoT technology in CNC machines, companies can monitor performance in real-time, leading to data-driven decision-making and predictive maintenance.

Tips: To leverage IoT capabilities, consider starting with a pilot project that focuses on a single CNC machine. This allows for effective testing of connectivity and data analytics before a full-scale implementation, minimizing disruptions in operations.

Moreover, IoT facilitates seamless communication between machines, enabling them to share real-time information regarding operational parameters. This interconnectedness not only enhances workflow efficiency but also helps identify bottlenecks promptly. Studies have shown that manufacturers adopting IoT solutions can experience a productivity increase of up to 20%. As businesses continue to embrace IoT in CNC machining, integrating advanced analytics and machine learning will further enhance operational capabilities, providing a competitive edge in the rapidly evolving industrial landscape.

Tips: Ensure that your workforce is equipped with the necessary training on IoT technologies. Upskilling employees will not only lead to smoother transitions during implementation but also foster an innovative culture that embraces technological advancements.

Market Dynamics: Demand and Supply Trends for CNC Machines in 2025

As we move towards 2025, the CNC machine market is anticipated to experience significant shifts driven by evolving demand and supply dynamics. According to a recent industry report by MarketsandMarkets, the CNC machine market is projected to reach approximately USD 100 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6% from 2020. This growth is largely influenced by the increasing automation in manufacturing processes and the rising need for precision and efficiency across various industrial sectors.

On the supply side, the industry is witnessing advancements in technology that enhance the capabilities of CNC machines, such as the incorporation of IoT and AI. These innovations not only improve operational efficiency but also enable predictive maintenance, which can significantly reduce downtime. Moreover, with the global push for sustainability, manufacturers are adopting eco-friendly practices in the production of CNC machines, further influencing market dynamics. Reports indicate that manufacturers investing in sustainable technologies could see an uptick in market demand as businesses increasingly prioritize green manufacturing practices in their operations.

Simultaneously, the demand for CNC machines is being driven by sectors such as aerospace, automotive, and medical devices, which require high precision and complex machining capabilities. According to a report by ResearchAndMarkets, the aerospace sector alone is expected to demand a substantial increase in CNC technology by 2025, fueled by the resurgence in air travel and the need for lighter, more fuel-efficient aircraft components. This trend highlights the necessity for industries to adapt and invest in advanced CNC technologies to meet the growing demands of the market.

Related Posts

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

What is the Future of CNC Machine 3D Printer Technology

-

Top Home CNC Machines for Beginners and Hobbyists in 2023

-

What is an Industrial CNC Milling Machine and How Does It Work?

-

2025 Top 5 Precision CNC Milling Machines for Enhanced Manufacturing Efficiency

-

Revolutionizing Manufacturing: The Essential Guide to CNC Machine Industrial Innovations