METROM’s

Blog

METROM’s

Blog

Top Tips for Choosing the Right Laboratory Sample Pulverizer?

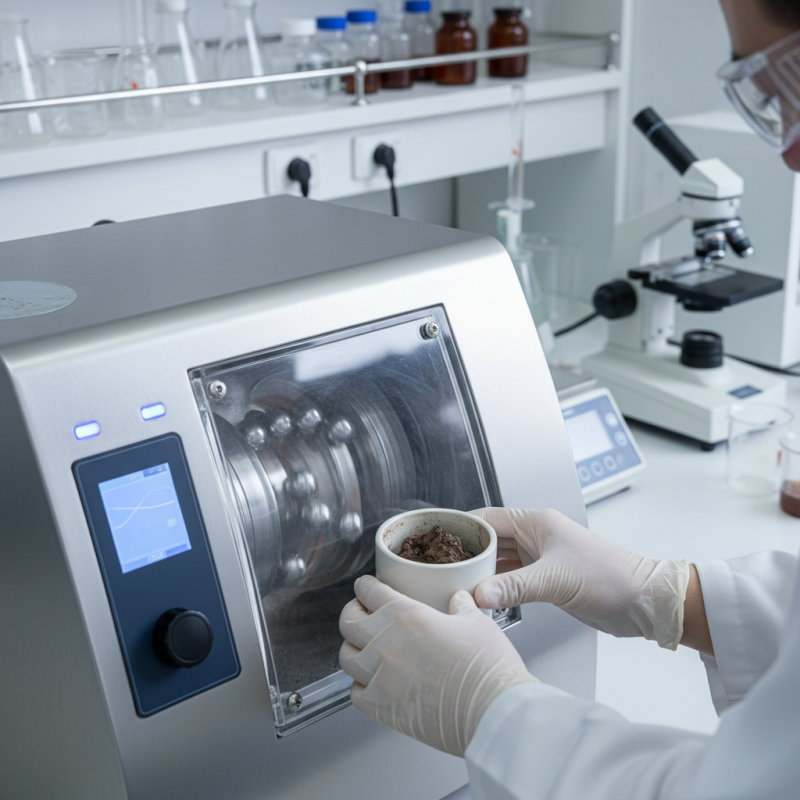

Choosing the right laboratory sample pulverizer is crucial for consistent and accurate results. As Dr. Emily Carter, a leading expert in material science, emphasizes, "The right pulverizer can make or break your research." In laboratories, sample preparation can influence the outcome significantly. Selecting a suitable pulverizer is often not straightforward. Many options exist, each with unique features and limitations.

One key aspect to consider is the material to be processed. Different pulverizers work best with specific substances. An incorrect choice may lead to contamination and unreliable data. Even the best equipment can fail if not matched to the sample type. Furthermore, some laboratories overlook maintenance needs. An improperly maintained pulverizer can yield inconsistent results, posing a risk to ongoing research.

Users must reflect on their specific requirements and the operational environment. The ideal laboratory sample pulverizer should serve distinct needs efficiently. A mismatch can result in wasted resources and time. It is essential to ask critical questions about functionality, efficiency, and usability. Making informed choices will ultimately enhance research quality and productivity.

Understanding the Importance of a Laboratory Sample Pulverizer

Laboratory sample pulverizers play a crucial role in material analysis. They help prepare samples for various tests, ensuring accurate results. Studies show that over 70% of inaccurate laboratory results stem from poor sample preparation. Therefore, selecting the right pulverizer is essential for any research or testing facility.

When choosing a pulverizer, consider sample size and hardness. Each material requires specific equipment to achieve optimal results. For example, some materials might require pre-crushing before grinding. Data from industry reports indicate that improper sample handling can lead to data variabilities of up to 15%. This highlights the importance of equipment quality and suitability.

Additionally, think about maintenance and cleaning. Some pulverizers are more challenging to disassemble, making thorough cleaning difficult. A recent survey revealed that 60% of lab technicians face challenges due to inadequate cleaning capabilities. Regular maintenance is vital for consistent results. Choosing the right laboratory sample pulverizer is not just about functionality; it's about ensuring that your results are trustworthy and reproducible.

Key Features to Look for in a Pulverizer

When selecting a laboratory sample pulverizer, specific features are essential. First, consider the material construction. A durable design ensures longevity and resistance to wear. Stainless steel or hardened materials are often preferred to withstand frequent use. Additionally, the size of the grinding chamber is critical. A larger chamber can handle bigger samples, but often requires more power.

Another important aspect is the adjustment of particle size. Some pulverizers allow for precise control, enabling you to achieve the desired fineness. This flexibility is vital for different applications. Moreover, ease of cleaning should not be overlooked. A machine that disassembles easily saves time and prevents cross-contamination.

While functionality is key, don't forget power consumption. Some models may be powerful but inefficient. Look for options that balance performance with low energy use. Reflecting on these aspects can help identify the right pulverizer for your needs.

Top Tips for Choosing the Right Laboratory Sample Pulverizer

This chart illustrates the importance rating of key features to consider when choosing a laboratory sample pulverizer. The ratings range from 1 to 10, highlighting the emphasis on particle size reduction and material compatibility as top priorities for effective pulverization.

Types of Laboratory Pulverizers and Their Applications

When selecting a laboratory sample pulverizer, understanding the types and their applications is crucial. Laboratory pulverizers come in various forms, including ball mills, hammer mills, and jet mills. Each type serves different purposes. For example, ball mills are great for fine grinding, while hammer mills are better for coarse materials. Make sure you know the materials you will be working with.

Consider the specific needs of your laboratory. The volume of samples can influence your choice. If you process large amounts, a high-capacity pulverizer might be necessary. On the other hand, small-scale operations may only require compact models. It's essential to assess your workflow and the anticipated output.

Tips for choosing the right pulverizer include evaluating particle size requirements. Do you need a specific grain size? Then select a unit that can achieve that. Always consider durability and maintenance. A robust machine can save time and costs in long-term operations. Remember, not every machine will meet your needs perfectly. Adjustments might be necessary over time.

Factors to Consider When Selecting a Pulverizer

When selecting a laboratory sample pulverizer, several key factors must be weighed. The intended use dramatically influences the choice. For instance, if you're dealing with materials like minerals or plastics, you may require different specifications. According to industry reports, almost 75% of laboratory operations report frequent equipment breakdowns stemming from inappropriate machinery selections.

Another important aspect is the particle size reduction capability. Different applications necessitate specific particle sizes. Ideal pulverizers should achieve consistent results within a defined range. Research indicates that a pulverizer's efficiency can drop by 30% if it isn’t well-suited for the material type. It’s crucial to assess the design features, as these often dictate the operational efficiency and maintenance requirements.

Furthermore, consider the energy consumption and operational costs. A poorly chosen pulverizer may incur double the energy costs over time. Many facilities overlook this, focusing solely on upfront costs. According to data from industry analysts, an optimized pulverizer can improve energy efficiency by up to 40%. Therefore, evaluating long-term operational costs alongside initial investments is vital to ensure a positive return on investment.

Maintenance Tips for Laboratory Sample Pulverizers

Maintaining laboratory sample pulverizers is crucial for optimal performance. Regular cleaning is essential to prevent contamination. Use a soft brush to clear away residues. Sometimes, stubborn materials may require scrubbing. Pay attention to wear on grinding surfaces; they need checking often. If they show signs of damage, consider replacement to ensure accuracy.

Calibration should be part of your routine maintenance. Miscalibrated equipment can yield inaccurate results. Follow the manufacturer's guidelines for calibration frequency. Tracking usage can help; more use may mean more frequent checks. While it’s easy to overlook this, doing so is key to data integrity.

Don’t forget about the power source. A poor connection can interrupt operations. Regularly check cords and connections. Make sure they are in good condition. It’s easy to assume everything works until it doesn’t. A little vigilance can prevent significant issues later. Always document your maintenance activities for reference.

Top Tips for Choosing the Right Laboratory Sample Pulverizer

| Tip | Description | Maintenance Frequency | Key Considerations |

|---|---|---|---|

| Determine Sample Type | Choose pulverizers suitable for the specific materials you will be using, such as minerals or organic samples. | Before each use | Material compatibility |

| Select the Right Size | Consider the volume of samples and choose a pulverizer that can handle the required amount. | Monthly | Sample volume and batch size |

| Check Grinding Speed | Higher speeds can reduce processing time but may affect sample quality; find a balance. | Quarterly | Speed vs. quality |

| Assess Durability | Choose materials and construction quality that ensure longevity and reliability. | Biannually | Material strength |

| Plan for Easy Maintenance | Select models that allow for easy cleaning and parts replacement. | After every use | Ease of cleaning |