METROM’s

Blog

METROM’s

Blog

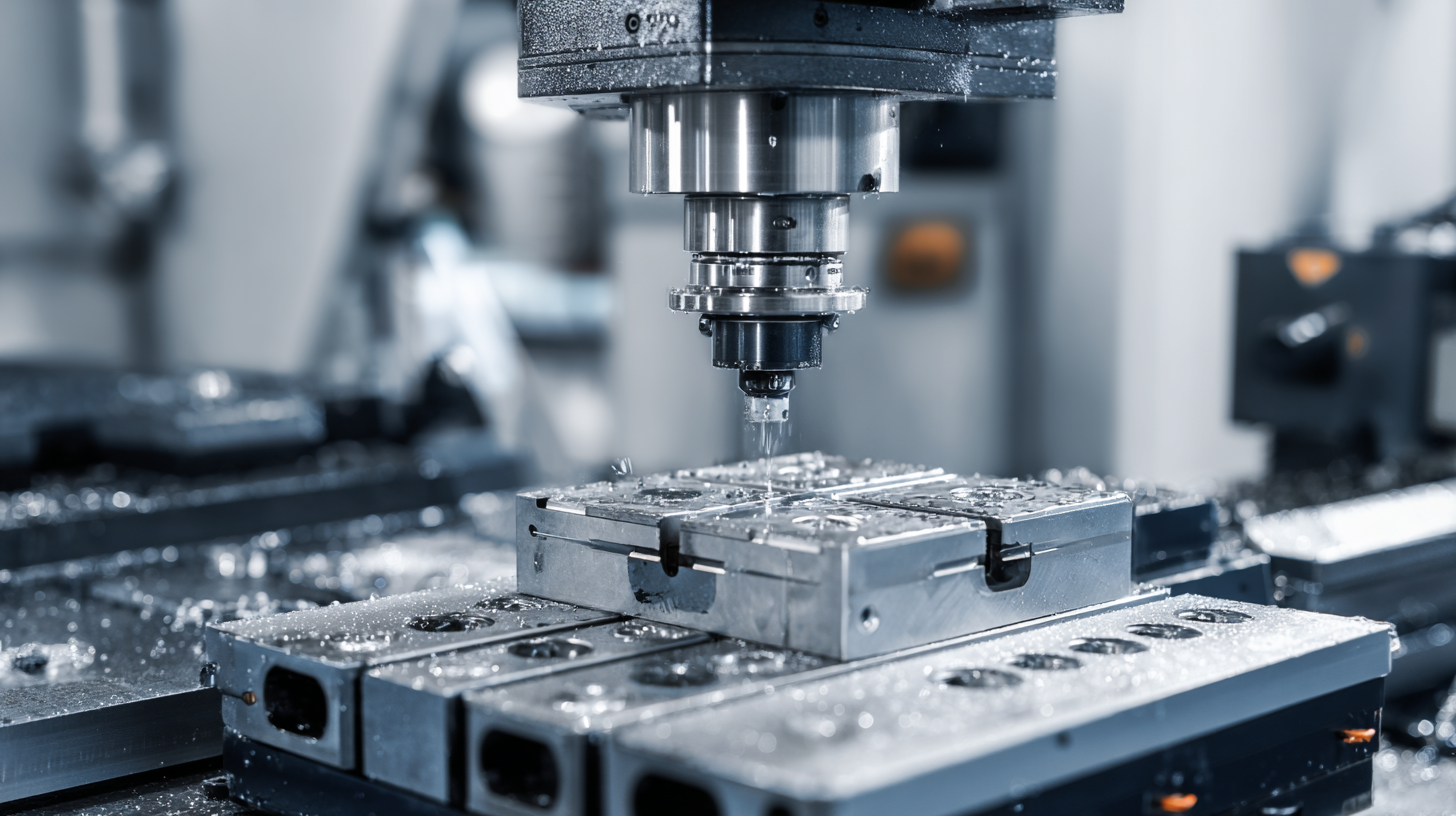

Unveiling the Secrets of Industrial CNC Milling Machines Driving Precision and Efficiency in Manufacturing

The industrial CNC milling machine has become a cornerstone of modern manufacturing, playing a vital role in driving precision and efficiency across various sectors. According to a report by MarketsandMarkets, the global CNC milling machine market is projected to reach USD 121 billion by 2025, growing at a CAGR of 6.1%. This growth underscores the increasing reliance on computer numerical control (CNC) technology to meet the demands for complex part production with high accuracy. The incorporation of advanced features such as automated tool changers and multi-axis capabilities has propelled the capabilities of industrial CNC milling machines, allowing manufacturers to optimize their operations and reduce lead times. This article will delve into the intricacies of industrial CNC milling machines, exploring how they drive efficiency and enhance precision in the manufacturing landscape.

The Evolution of CNC Milling Machines: From Manual to Automation in the Manufacturing Sector

The evolution of CNC milling machines from manual operations to automated systems has dramatically transformed the manufacturing sector. Initially, manual mills required skilled operators to shape materials through labor-intensive processes. As technology advanced, the introduction of Computer Numerical Control (CNC) allowed for greater precision and efficiency. This shift not only reduced human error but also paved the way for complex designs that were previously unimaginable. With the integration of user-friendly interfaces and intuitive control systems, operators can now program intricate tasks with ease, significantly enhancing productivity.

Today, the incorporation of artificial intelligence (AI) marks the next phase in CNC technology. AI-driven innovations are set to further revolutionize precision manufacturing by optimizing workflows, minimizing waste, and improving quality control. The market for CNC machines is projected to expand significantly by 2032, reflecting the growing demand for these advanced tools. As industries embrace automation and intelligent manufacturing solutions, the future of CNC milling promises unprecedented advancements, solidifying its role as a cornerstone of modern industrial fabrication.

Key Statistics on Precision: How CNC Milling Machines Illuminate Product Tolerances

The global CNC machine market is poised for significant growth, projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, showcasing a robust CAGR of 9.9%. This growth is driven by the burgeoning demand for high-precision machining solutions, as manufacturers increasingly rely on CNC milling machines to meet stringent product tolerances. The ability of CNC technology to deliver unparalleled accuracy is essential for industries requiring tight tolerances, thus enhancing overall product quality and reducing waste.

As the landscape of CNC machining evolves, advancements in technology, particularly in multi-axis machining centers, are set to redefine manufacturing processes. The multi-axis machining centers market is expected to escalate from an estimated USD 79,361.7 million in 2024 to a remarkable USD 134,924.2 million by 2033. This surge highlights the industry's shift toward more sophisticated machining techniques that not only increase efficiency but also ensure enhanced precision in product design. Furthermore, the integration of artificial intelligence within CNC operations is revolutionizing how manufacturers approach precision and efficiency, paving the way for a more innovative future in industrial machining.

Maximizing Efficiency: The Impact of CNC Milling on Manufacturing Cycle Time Reduction

CNC milling machines have revolutionized the manufacturing landscape by significantly reducing cycle times without compromising on precision. The intricate programming capabilities of CNC (Computer Numerical Control) technologies allow for highly specific and complex machining processes that can be completed in a fraction of the time required by traditional methods. This accelerated production cycle not only boosts output but also enhances the overall efficiency of operations, enabling manufacturers to meet increased demands with agility.

Moreover, the automation offered by CNC milling minimizes human errors and streamlines workflows, leading to further decreases in production time. By integrating computer programming with precision machining, manufacturers can quickly shift between different production runs, adapting to market trends and customer needs more swiftly. This adaptability not only fulfills immediate manufacturing requirements but also positions companies competitively in a fast-paced market, allowing for rapid response times and improved resource allocation. Such advancements in technology redefine operational excellence, ultimately driving higher profitability and sustainability within the manufacturing sector.

Real-World Applications: Industries Revolutionized by Advanced CNC Milling Technologies

Advanced CNC milling technologies have profoundly transformed various industries, enhancing precision and efficiency in manufacturing processes. According to industry reports, the CNC machine market is projected to grow significantly, driven by the adoption of digital manufacturing technologies that have substantially improved productivity across a wide range of sectors. This evolution is pivotal, especially in industries such as aerospace, automotive, and healthcare, where precision is paramount. The innovative integration of AI within CNC milling machines allows for real-time adjustments and optimizations in manufacturing workflows, leading to reduced waste and improved resource allocation.

Furthermore, the implementation of intelligent robotics has begun to reshape industrial applications, particularly in settings requiring complex assembly and fabrication tasks. Recent surveys have highlighted trends indicating a robust future for 3D printing and CNC milling, with executives noting increased investment in technologies that merge AI and robotics into traditional machining methods. This synergy not only boosts operational efficiency but also revolutionizes approaches to production scheduling and task allocation, making it possible to manage multi-robot systems effectively. As manufacturers continue to embrace these advanced CNC milling technologies, the landscape of industrial production will likely evolve, setting new standards for quality and efficiency.

Future Trends in CNC Milling: Innovations Driving Improvements in Precision and Efficiency

The future of CNC milling is being profoundly shaped by innovative technologies such as Artificial Intelligence (AI) and advanced robotics. These developments are revolutionizing machining processes, enhancing not only precision but also operational efficiency. The CNC machine tools market is projected to grow significantly, driven by the increasing demand for high-precision and multi-axis machining centers. With AI's capability to redefine operational workflows, manufacturers can expect substantial improvements in productivity across a wide range of industrial applications.

Additionally, the trend towards digital manufacturing technologies is gaining momentum, promising to streamline production processes. The integration of sophisticated software systems with traditional CNC machines is enabling real-time monitoring and optimization of machining operations. This shift towards automation and data-driven decision-making is critical for industries aiming to meet the growing demands for quality and speed in production, thus paving the way for a new era of industrial efficiency.

Unveiling the Secrets of Industrial CNC Milling Machines Driving Precision and Efficiency in Manufacturing - Future Trends in CNC Milling

| Dimension | Measurement | Trend/Innovation |

|---|---|---|

| Precision Level | ±0.01 mm | Advanced Sensing Technologies |

| Speed | 5000 RPM | High-Speed Machining |

| Accuracy | 0.005 mm | Automation and AI Integration |

| Production Rate | 100 parts/hour | Smart Manufacturing Techniques |

| Surface Finish | Ra 0.8 μm | New Cutting Tools and Coatings |

Related Posts

-

Top Strategies for Maximizing Efficiency with the Best Industrial CNC Milling Machine

-

How to Optimize CNC Machine Milling Efficiency: Insights from Industry Data

-

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

-

Overcoming Common Challenges with Industrial CNC Milling Machines for Global Buyers

-

7 Best CNC Machine Innovations Transforming Manufacturing in 2023

-

How to Optimize Efficiency with CNC Industrial Machines for Your Business