METROM’s

Blog

METROM’s

Blog

Revolutionizing Custom Designs: How CNC Machine Printing Transforms Industries

In recent years, the advent of CNC machine printing has dramatically transformed the landscape of custom design across various industries. According to market research by Grand View Research, the global CNC machining market is expected to reach over $100 billion by 2027, demonstrating a robust CAGR driven by advancements in automation and precision engineering. CNC machine printing is at the forefront of this revolution, enabling manufacturers to achieve unprecedented levels of accuracy and complexity in their designs. This technology not only streamlines production processes but also significantly reduces waste, aligning with sustainability goals that are increasingly becoming a priority in industrial operations. As industries ranging from aerospace to consumer products adopt CNC machine printing, the potential for innovation and personalization in design continues to expand, marking a pivotal shift in how products are conceptualized and made.

Understanding CNC Machine Printing and Its Capabilities

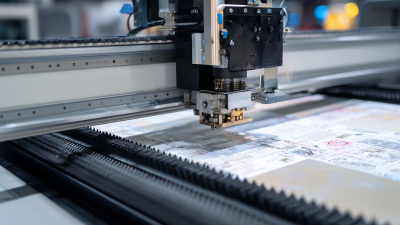

CNC machine printing, or computer numerical control printing, has emerged as a transformative technology in various industries, providing unparalleled precision and customization capabilities. By utilizing advanced software to control cutting, shaping, and engraving processes, CNC machines are able to create intricate designs that were once difficult, if not impossible, to achieve by hand. This technology allows for the production of unique products tailored to specific customer needs, significantly enhancing the design process and minimizing waste.

The capabilities of CNC machine printing extend beyond mere customization. These machines can work with a wide range of materials, including wood, metal, and plastics, offering versatility across industries such as manufacturing, automotive, and even fashion. Furthermore, the automation involved in CNC machining not only speeds up production but also elevates the consistency of the final product, ensuring high-quality outputs each time. As industries continue to embrace this technology, the possibilities for innovative designs and applications seem endless, paving the way for a new era of manufacturing and creativity.

Impact of CNC Machine Usage Across Industries in 2023

This bar chart illustrates the percentage of CNC machine usage across various industries in 2023, showcasing how CNC technology is revolutionizing custom designs.

Exploring the Benefits of Custom Designs in Various Industries

The advent of CNC machine printing has dramatically transformed various industries by enabling a new era of custom designs. According to a report by Deloitte, the global custom manufacturing market is projected to reach $36 billion by 2025, driven largely by advancements in technologies like CNC machining. This technology facilitates the creation of intricate and precise designs tailored to the specific needs of businesses, allowing for greater flexibility and efficiency in production processes.

In the automotive industry, for example, companies are leveraging CNC machine printing to produce customized parts that fit seamlessly into their assembly lines. A study from McKinsey highlights that manufacturers who adopt custom CNC machining can reduce lead times by up to 50%, enhancing their ability to meet consumer demands quickly. Similarly, in the healthcare sector, personalized medical devices, such as prosthetics and orthodontic devices, are being manufactured using CNC technology, leading to better patient outcomes and satisfaction. As various industries embrace these innovations, the ability to implement custom designs is becoming a crucial competitive advantage, demonstrating the transformative power of CNC machine printing.

Key Steps to Implementing CNC Technology in Your Business

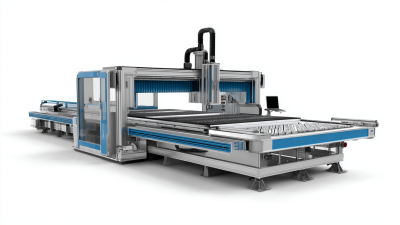

Implementing CNC technology in your business involves several key steps that can transform not only manufacturing processes but also overall operational efficiency.

First, it is crucial to assess your current production workflows and identify areas where CNC machinery can enhance precision and reduce turnaround times. The shift towards digital manufacturing technologies allows companies to significantly boost productivity, embracing automation and AI to streamline machining tasks effectively.

Next, investing in the right infrastructure is essential. Selecting the appropriate CNC machinery tailored to your specific needs will enable you to harness the full potential of modern manufacturing practices. This includes integrating Industry 4.0 innovations, where real-time data monitoring and the Internet of Things (IoT) can enhance machine performance, resulting in improved product quality and waste reduction.

Furthermore, providing training for staff to operate and maintain CNC equipment is critical for maximizing these advanced technologies' benefits, ensuring a smooth transition to a more automated and efficient production environment.

Case Studies: Success Stories of CNC Innovations in Custom Design

The integration of CNC machine printing has ushered in a new era of customization across various industries, showcasing groundbreaking success stories that highlight its transformative power. A notable case study in the automotive sector reveals that companies using CNC technology for custom parts have reduced production times by up to 50%, significantly accelerating their go-to-market strategies. According to a recent report by MarketsandMarkets, the CNC machine market is projected to reach $100 billion by 2026, emphasizing the growing reliance on these innovative tools for customized manufacturing.

In the realm of aerospace, Boeing has implemented CNC machining in the creation of complex components. This shift not only improved precision but also cut costs by approximately 30%, as noted in an aerospace technology survey. Additionally, the furniture design industry has benefited from CNC advancements, allowing artisans to craft intricate patterns and designs that were previously unattainable. The global CNC machining industry is expected to grow at a CAGR of 6.3% from 2021 to 2028, driven by these success stories, which serve as compelling evidence of CNC printing's capability to revolutionize custom design across different sectors.

In the realm of aerospace, Boeing has implemented CNC machining in the creation of complex components. This shift not only improved precision but also cut costs by approximately 30%, as noted in an aerospace technology survey. Additionally, the furniture design industry has benefited from CNC advancements, allowing artisans to craft intricate patterns and designs that were previously unattainable. The global CNC machining industry is expected to grow at a CAGR of 6.3% from 2021 to 2028, driven by these success stories, which serve as compelling evidence of CNC printing's capability to revolutionize custom design across different sectors.

Future Trends of CNC Machine Printing and Its Impact on Industries

The future trends of CNC machine printing are poised to significantly impact a variety of industries by enhancing customization and efficiency. As technology continues to advance, we can expect CNC machines to adopt more sophisticated software and automation capabilities, allowing for real-time adjustments and precision in the manufacturing process. This adaptability not only streamlines production but also opens new avenues for personalized design, enabling companies to cater to the unique preferences of their customers.

Moreover, the integration of artificial intelligence and machine learning will revolutionize how CNC machine printing operates. These technologies will facilitate predictive maintenance, ensuring minimal downtime and optimizing operational efficiency. Industries such as aerospace, automotive, and medical will particularly benefit from this evolution, as they require high precision and reliability. The ability to produce intricate designs quickly and cost-effectively will likely redefine standards in manufacturing, pushing businesses to innovate and stay competitive in a rapidly changing market.

Related Posts

-

Unmatched Precision and Innovation Chinese Manufacturing Leads the Way in High Precision Milling Machines

-

How to Choose the Right Manufacturing Machines for Your Production Needs

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

The Ultimate Guide to CNC Machine Tools Understanding Trends Technologies and Market Dynamics

-

How to Choose the Right Axis CNC Machine for Your Business Needs