METROM’s

Blog

METROM’s

Blog

5 Incredible Reasons Why 5 Axis Milling Machines Are Revolutionizing Manufacturing Efficiency

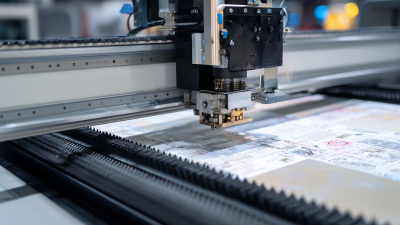

In today’s fast-paced manufacturing landscape, the introduction of advanced technologies is paramount to staying competitive, and the 5 axis milling machine is at the forefront of this revolution. With the ability to perform complex machining tasks in a single setup, these machines are transforming traditional manufacturing processes by significantly enhancing precision, efficiency, and productivity.

In this blog, we will explore five incredible reasons why 5 axis milling machines are not just a trend, but a game-changer for manufacturers across various industries. From streamlining workflows to minimizing material waste, the advantages of integrating this sophisticated machinery into production lines are profound.

Join us as we dive deeper into how 5 axis milling machines can elevate your manufacturing efficiency to unprecedented heights.

The Power of Precision: How 5 Axis Milling Machines Improve Accuracy

In the ever-evolving landscape of manufacturing, 5 axis milling machines are at the forefront of precision engineering. Their ability to operate on multiple dimensions simultaneously allows for intricate designs and complex geometries that traditional machines simply cannot achieve. This enhanced capability leads to significant improvements in accuracy, ensuring that components fit together seamlessly and function as intended. As industries shift towards more intricate projects, the role of 5 axis milling becomes indispensable.

One key tip for optimizing the use of 5 axis milling machines is proper programming. Using advanced CAM software can dramatically reduce errors and streamline the manufacturing process. Additionally, regular calibration of the machinery is essential. By ensuring that your 5 axis machine is finely tuned and properly maintained, you can continue to achieve remarkable precision in your outputs.

Another effective strategy is to invest in high-quality tooling. Precision tools are crucial for maximizing the efficiency of 5 axis milling operations. A sharp, well-designed cutting tool can enhance surface finish and contribute to the overall accuracy of the final product. By focusing on these aspects, manufacturers can leverage the full potential of their 5 axis milling machines and truly revolutionize their production processes.

Streamlining Operations: The Time-Saving Benefits of 5 Axis Milling

The landscape of manufacturing is undergoing a significant transformation with the advent of 5-axis milling machines. These advanced tools are streamlining operations by enabling intricate machining processes to take place in a single setup, drastically reducing the time spent on repositioning workpieces. This capability not only accelerates production cycles but also minimizes the risk of errors that can arise from multiple setups, ensuring that manufacturers stay competitive in a fast-paced market.

Moreover, the integration of digital technologies further enhances the efficiency of 5-axis milling. With capabilities such as full CAD/CAM/CAE CNC integration, manufacturers can achieve a higher degree of accuracy and extend tool life, all while optimizing overall productivity. This holistic approach to machining allows for precise execution of complex designs, particularly in sectors like aerospace where tolerances are critical. As industries adopt these technologies, the efficiency gains and time savings provided by 5-axis milling will continue to revolutionize manufacturing processes.

Versatility Unleashed: Adapting to Complex Designs with 5 Axis Technology

The advent of 5-axis milling technology has undeniably transformed the manufacturing landscape, particularly in its ability to cater to complex designs. This advanced machining process allows manufacturers to produce intricate geometries that traditional 3-axis machines simply cannot handle. For instance, recent studies indicate that 5-axis machining can reduce manufacturing lead times by up to 30%, thereby streamlining production processes and maximizing efficiency.

Moreover, the flexibility of 5-axis machines enables manufacturers to modify designs on-the-fly, accommodating the evolving demands of industries such as aerospace, automotive, and medical devices. According to the International Journal of Advanced Manufacturing Technology, parts produced using 5-axis milling demonstrated a 20% improvement in surface finish quality compared to their 3-axis counterparts. This capability not only enhances product performance but also minimizes waste by maximizing material utilization.

Tip: To fully leverage 5-axis technology, invest in training your operators on advanced programming techniques, as this will ensure optimal machine performance and the ability to exploit the full range of machining capabilities.

Additionally, consider integrating CAD/CAM software to streamline the design-to-manufacturing process. This integration can significantly enhance your design precision and reduce potential errors, ultimately leading to improved production outcomes. By embracing these strategies, manufacturers can thrive in a competitive environment.

Cost-Effectiveness: The Long-Term Financial Benefits of Investing in 5 Axis Machining

Investing in 5-axis milling machines presents substantial long-term financial benefits for manufacturers. A recent report highlights that companies utilizing advanced machining technologies can reduce production costs by up to 20% while increasing productivity by upwards of 30%. This efficiency stems from the ability of 5-axis machines to perform complex operations in a single setup, significantly minimizing labor and material waste. As industries strive for cost-effectiveness, the integration of such machinery becomes pivotal.

Moreover, the economic implications extend beyond mere savings. A study on advanced manufacturing solutions demonstrates that firms leveraging 5-axis technology can enhance their market competitiveness, leading to a potential revenue increase of 25%. This is increasingly pertinent as global manufacturing trends lean towards automation and precision, aligning with broader technology-driven efficiencies seen in various sectors. The ability to produce high-quality components at a reduced cost positions manufacturers to capitalize on emerging market demands and sustain long-term growth.

5 Incredible Reasons Why 5 Axis Milling Machines Are Revolutionizing Manufacturing Efficiency - Cost-Effectiveness: The Long-Term Financial Benefits of Investing in 5 Axis Machining

| Dimension | Traditional Machining | 5 Axis Machining | Long-Term Savings (%) |

|---|---|---|---|

| Setup Time | 3 hours | 1 hour | 67% |

| Machining Accuracy | ±0.01 mm | ±0.005 mm | |

| Material Waste | 15% | 8% | 47% |

| Production Speed | 20 parts/hour | 35 parts/hour | 75% |

| Labor Costs | $30,000/year | $20,000/year | 33% |

Enhancing Production Rates: How 5 Axis Milling Boosts Manufacturing Output

The evolution of manufacturing technology has led to significant enhancements in production rates, and one of the standout advancements is the 5-axis milling machine. Unlike traditional machining methods, which often require multiple setups and adjustments, 5-axis milling allows for simultaneous movement along five different axes. This capability not only reduces the time taken to create complex parts but also increases precision, making it an essential tool in high-demand industries such as aerospace and automotive.

The efficiency boost offered by 5-axis milling machines translates directly into higher manufacturing output. By minimizing the number of setups required for intricate components, manufacturers can streamline their workflows significantly. Additionally, the ability to create parts with complex geometries in a single operation reduces waste and turnaround time, enabling faster project completions. This not only meets the increasing demands for quick production cycles but also accommodates the customization that modern-day consumers expect. As a result, companies adopting this technology find themselves at the forefront of innovation, driving both productivity and profit margins to new heights.

Related Posts

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

Unmatched Precision and Innovation Chinese Manufacturing Leads the Way in High Precision Milling Machines

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

The Future of Precision Manufacturing: Advancements in CNC Milling Machines