METROM’s

Blog

METROM’s

Blog

Unwavering Quality and Reliability of China's Best Precision CNC Milling Machines for Global Buyers

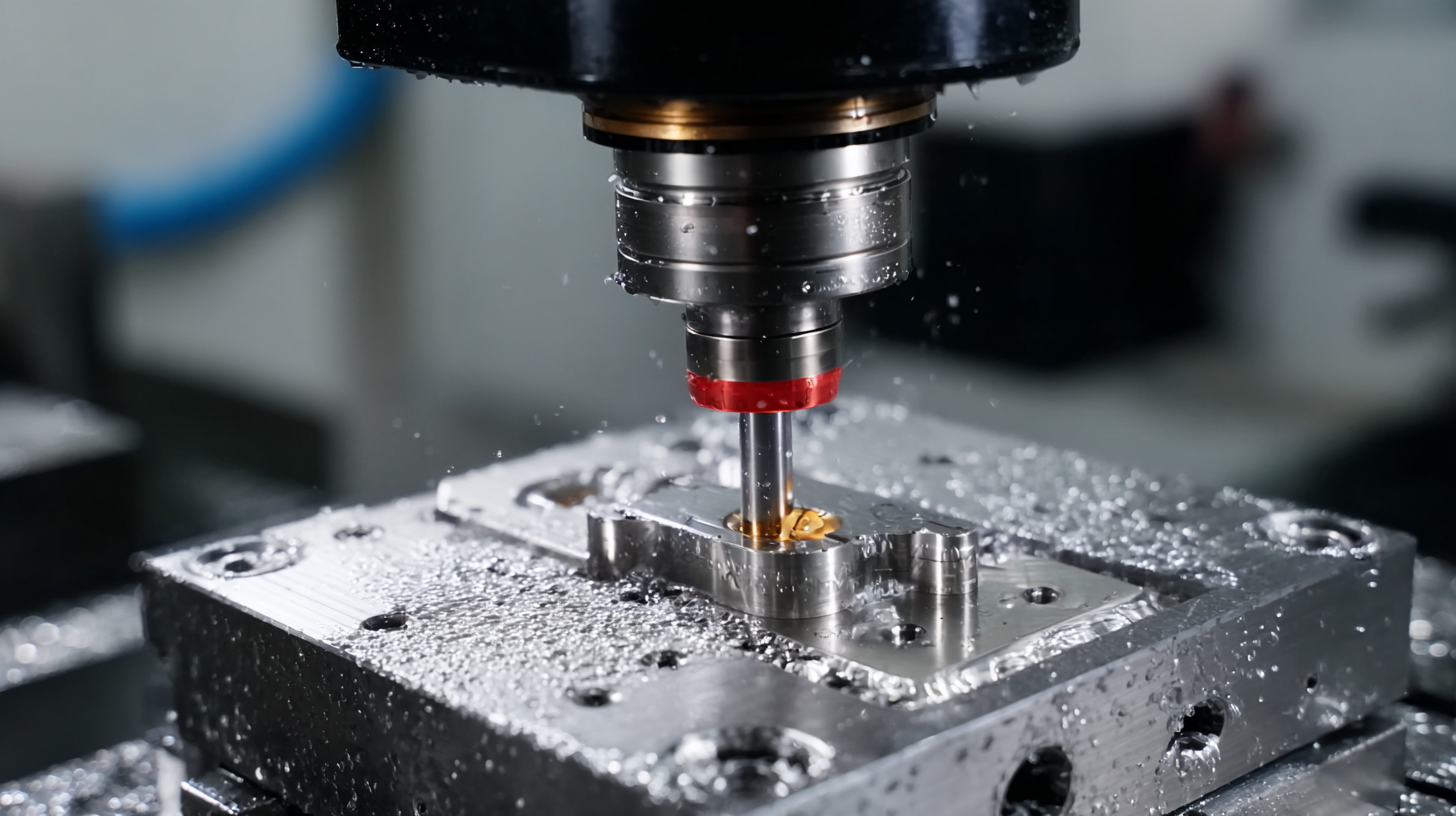

In the rapidly evolving landscape of manufacturing technology, precision CNC milling machines represent a pivotal advancement for global buyers seeking unparalleled quality and reliability. As industries around the world strive for efficiency and precision, China's best precision CNC milling machines have emerged as a vital solution for manufacturers aiming to stay competitive. With the advent of Industry 2025 technology trends, it becomes essential to not only understand the capabilities of these machines but also to leverage top strategies for their implementation. This blog will delve into the unwavering quality and reliability of China’s precision CNC milling machines, exploring how they meet the rigorous demands of modern manufacturing while fostering innovation and precision in production processes.

Unraveling the Precision: What Makes CNC Milling Machines Stand Out in the Market

When it comes to precision engineering, CNC milling machines stand at the forefront, especially those manufactured in China. The meticulous construction and cutting-edge technology embedded in these machines make them immensely sought after by global buyers. One significant factor that makes CNC milling machines exceptional is their ability to achieve remarkable accuracy and repeatability, which is essential for complex manufacturing processes.

Tips: When selecting a CNC milling machine, it's crucial to assess the machine's specifications, such as spindle speed, feed rate, and tolerance levels. These parameters play a vital role in determining the machine’s overall performance and suitability for your specific needs. Additionally, consider the after-sales support and warranty offered by the manufacturer, as these can greatly affect your operational efficiency and investment security.

Another distinguishing feature of China's CNC milling machines is their adaptability. These machines are often designed to accommodate a variety of materials, from metals to plastics, making them versatile for different industries. The integration of user-friendly software further enhances their usability, allowing operators to execute complex designs with ease while minimizing the learning curve.

Tips: Look for machines that provide comprehensive training resources or tutorials, as this can significantly help in leveraging the full potential of the CNC milling machine. Also, don't hesitate to request a demo to assess the machine’s capabilities first-hand before making a purchase decision.

Key Features to Look for in High-Quality CNC Milling Machines

When choosing a high-quality CNC milling machine, there are several key features that buyers should keep in mind. Precision is paramount; look for machines that offer high accuracy and repeatability to ensure the best outcomes in your milling projects. Additionally, consider the rigidity of the machine. A robust structure minimizes vibrations, allowing for finer finishes and longer tool life, which is essential for maintaining production efficiency.

Another important aspect is the machine's software capabilities. Modern CNC milling machines come equipped with advanced programming interfaces that enhance usability and integrate seamlessly with various design software. Buyers should seek machines that support multiple file formats and offer user-friendly control systems. This ensures that operators can easily program, monitor, and modify milling operations to achieve the best results.

Tips for prospective buyers include investing in a machine that has a proven track record in your specific industry. Researching user reviews and case studies can provide valuable insights into performance and reliability. Additionally, always check if the manufacturer offers comprehensive support and warranty options, as this can be critical in maintaining machine uptime and performance.

The Role of Advanced Technology in Enhancing CNC Milling Performance

The global CNC machine market is poised for significant growth, projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This impressive trajectory is largely driven by advancements in technology enhancing CNC milling performance. The integration of artificial intelligence in machining processes stands on the cutting edge of this revolution, promising improvements in precision manufacturing and operational efficiency.

As precision machining continues to evolve, it is crucial for manufacturers to stay updated on emerging technologies. Tips for optimizing CNC milling performance include regularly updating machine software to leverage the latest features and investing in training for operators to ensure they can utilize advanced technologies effectively. Additionally, focusing on sustainable practices by utilizing cutting fluids responsibly can enhance both performance and environmental stewardship.

The machine tools market, valued at $97.1 billion in 2024, is set to achieve remarkable growth, with projections indicating it could reach $196 billion by 2034. This emphasizes the relentless pursuit of precision and efficiency in manufacturing processes. Companies that harness the power of advanced technology, such as AI and next-gen CNC capabilities, will undoubtedly lead the way in meeting the global demand for high-quality machining solutions.

Essential Checklist for Evaluating CNC Milling Machines for Your Business

When it comes to investing in CNC milling machines, global buyers must consider a comprehensive checklist to ensure their chosen equipment meets business needs. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117.72 billion by 2025, reflecting the growing demand for precision machining. This growth highlights the necessity of understanding the criteria for evaluation.

First, accuracy and precision are paramount. Machining tolerances of ±0.01 mm or better are often expected from high-end CNC milling machines. Buyers should look for machines equipped with advanced control feedback systems that enhance accuracy, as noted by a study published in the International Journal of Advanced Manufacturing Technology. Additionally, consider the machine's operational efficiency, which can significantly impact production costs. Machines with high spindle speeds and feed rates, such as those exceeding 20,000 RPM, can improve processing time, thereby increasing productivity.

Lastly, the reliability of after-sales support and availability of spare parts cannot be overstressed. A survey by the Association for Manufacturing Technology indicates that 30% of machine downtime is attributed to maintenance issues. Therefore, ensure that the supplier provides robust technical support and readily available components. Adopting this checklist will help businesses invest wisely in CNC milling technology that delivers long-term value.

Unwavering Quality and Reliability of China's Best Precision CNC Milling Machines for Global Buyers

| Feature | Value | Importance |

|---|---|---|

| Accuracy | ±0.005 mm | High |

| Maximum Spindle Speed | 12000 RPM | Medium |

| Table Size | 1000 x 500 mm | High |

| Control System | CNC Controller | High |

| Cooling System | Integrated Cooling | Medium |

| Material Compatibility | Aluminum, Steel, Plastic | High |

| Power Consumption | 5 kW | Medium |

Global Trends Shaping the Future of CNC Milling Machinery in 2025

As we look ahead to 2025, the landscape of CNC milling machinery is set to evolve significantly, driven by technological advancements and shifting market demands. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100.3 billion by 2025, growing at a CAGR of 7.5% from 2020. This growth reflects the increasing adoption of automation and AI in manufacturing processes, making CNC machines not only more efficient but also smarter in optimizing production lines.

Moreover, the demand for precision and reliability in CNC milling machines is reshaping how manufacturers approach machinery design and functionality. As industries such as aerospace and automotive seek ever-greater precision, companies are incorporating advanced features like adaptive machining and real-time monitoring systems. A report from Grand View Research indicates that the precision machining market alone will witness a substantial increase, forecasting a growth rate of over 8% annually through 2025. This trend highlights the necessity for high-quality CNC milling machines that can meet rigorous industry standards, potentially positioning China's manufacturers as leaders in providing reliable solutions for global buyers.