METROM’s

Blog

METROM’s

Blog

Overcoming Common Challenges with Industrial CNC Milling Machines for Global Buyers

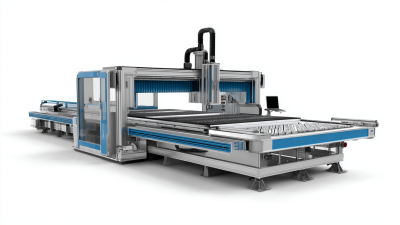

In the ever-evolving landscape of manufacturing, the role of the industrial CNC milling machine has become increasingly pivotal, especially for global buyers seeking to enhance their production capabilities. However, navigating the complexities associated with these advanced machines can pose significant challenges, from selecting the right model to optimizing operational efficiency. This blog aims to offer valuable insights into overcoming common pitfalls with industrial CNC milling machines, empowering buyers to make informed decisions.

Whether you are a seasoned professional or new to the world of CNC milling, understanding these hurdles and their solutions can lead to improved productivity, reduced downtime, and a smoother integration into your manufacturing processes. Join us as we explore practical tips and strategies tailored specifically for the global market, ensuring you can leverage the full potential of industrial CNC milling technology.

Benefits of CNC Milling Machines in Global Manufacturing Markets

CNC milling machines have revolutionized global manufacturing, providing unmatched precision and efficiency. As industries evolve, the demand for high-quality components continues to rise, propelling the growth of the CNC machine market, which is projected to surge from $101.22 billion in 2025 to $195.59 billion by 2032 at a CAGR of 9.9%. This expansion underscores the critical role these machines play in facilitating streamlined operations across various sectors, from aerospace to automotive.

One of the key advantages of CNC milling machines is their ability to produce complex parts with minimal human intervention. This automation not only enhances accuracy, reducing waste and production costs, but also allows manufacturers to increase output. Furthermore, CNC milling is adaptable, accommodating a wide range of materials, which makes it an ideal choice for global buyers looking to remain competitive in fast-changing markets. As manufacturers seek innovative solutions to common challenges, the integration of advanced CNC technologies will remain vital for driving productivity and meeting customer demands.

Key Challenges Faced by Global Buyers in CNC Milling Machine Acquisition

When global buyers embark on acquiring industrial CNC milling machines, they often encounter several common challenges that can complicate the purchasing process. One significant issue is the variation in specifications and capabilities across different manufacturers. Buyers may struggle to align their requirements with the right machine, leading to potential operational inefficiencies down the line.

Tip: Before initiating the purchase, create a detailed list of your production needs, including materials to be machined and desired tolerances. This will help streamline your communication with suppliers and ensure that you select a machine that meets your precise demands.

Another challenge is navigating international regulations and compliance standards, which can vary widely from one country to another. For global buyers, understanding these regulations is crucial to avoid costly delays and legal complications.

Tip: Engage a local expert or consultant familiar with regulatory requirements in both your home country and the manufacturer’s location. This can provide valuable insights into compliance and assist with necessary paperwork, ensuring a smoother acquisition process.

Lastly, the maintenance and support of CNC milling machines can pose a challenge, especially if buyers are unfamiliar with the service networks of different manufacturers. Without adequate support, production can suffer due to machine downtime.

Tip: Prioritize manufacturers that have established service centers in your country or region. Before buying, assess their customer service reputation and response times to ensure you have reliable support when needed.

Comparative Analysis: CNC Milling Machines vs. Traditional Machining Methods

When comparing CNC milling machines to traditional machining methods, it's essential to highlight the substantial advantages that CNC technology brings to the table. A report from Grand View Research indicates that the CNC machine market is expected to grow to $100 billion by 2025, driven by the precision and efficiency it offers over conventional techniques. Traditional machining often involves manual setup and operation, which can lead to inconsistencies and higher labor costs. In contrast, CNC milling machines automate processes, resulting in superior accuracy and reduced lead times—a crucial factor for global buyers who demand efficiency and quality.

**Tip:** When selecting a CNC milling machine, consider investing in advanced models that incorporate features like adaptive control algorithms. These innovations can further enhance productivity by adjusting cutting parameters in real-time, ensuring optimal performance.

Moreover, CNC milling's ability to perform complex geometries with minimal human intervention helps manufacturers achieve a high level of repeatability. According to a study by the Manufacturing Technology Association, companies utilizing CNC machines report up to 30% higher production rates than those relying on traditional methods. This efficiency not only reduces waste but also enables companies to scale production without compromising quality.

**Tip:** Regular maintenance of CNC machines is vital. Implementing a routine check can prevent costly downtimes and extend the life of the equipment, ensuring continuous and efficient operation for your manufacturing processes.

Comparison of CNC Milling Machines and Traditional Machining Methods

Evaluating CNC Machine Specifications: What Global Buyers Need to Know

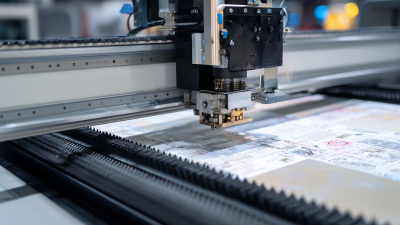

When evaluating CNC machine specifications, global buyers must navigate a landscape rich with technical jargon and performance metrics. A recent report from MarketsandMarkets projects the CNC machining market to reach USD 100 billion by 2025, driven by innovations in automation and precision engineering. This growth emphasizes the need for buyers to focus on key specifications, such as spindle speed, feed rate, and axis capabilities. For instance, machines that offer spindle speeds upwards of 20,000 RPM can significantly enhance productivity by reducing cycle times and improving finish quality in machining operations.

Moreover, understanding the differences in machine control systems is crucial for global buyers. A study by Mordor Intelligence indicates that the market for CNC controllers is expected to expand at a CAGR of over 7% through 2026. Buyers should consider the type of software—such as G-code compatibility and user interface features—that aligns with their operational needs. Additionally, integrating advanced features like adaptive control can optimize performance and reduce operational costs, making it essential for buyers to evaluate how these specifications can meet their long-term production goals.

Addressing Cost-Benefit Considerations for International CNC Milling Procurement

When considering the procurement of CNC milling machines, global buyers must navigate the crucial cost-benefit landscape that directly impacts their operational efficiency. According to a 2022 report by MarketsandMarkets, the CNC milling machine market is projected to reach USD 22.68 billion by 2028, growing at a CAGR of 8.3%, indicating a robust demand for these machines. This growth not only highlights the industry's potential but also emphasizes the need for buyers to carefully evaluate the total cost of ownership, which includes upfront acquisition costs, maintenance, and operational expenses.

Furthermore, a study conducted by Technavio reveals that while high-quality CNC milling machines can initially appear expensive, their long-term benefits, including increased precision and reduced waste, often lead to significant cost savings. For instance, organizations can reduce machining time by up to 30% with advanced CNC technologies. This means that while international buyers may face higher upfront costs for premium machines, the resulting efficiency can substantially outweigh these investments, making it critical to conduct a thorough cost-benefit analysis to ensure informed purchasing decisions.

Related Posts

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

Crafting Excellence in CNC Machining for Global Manufacturing Solutions