METROM’s

Blog

METROM’s

Blog

How to Optimize Efficiency with CNC Industrial Machines for Your Business

In today's fast-paced manufacturing landscape, optimizing efficiency is crucial for businesses aiming to stay competitive and meet growing demands. One of the most effective ways to enhance operational productivity is through the strategic use of CNC industrial machines. These advanced tools not only streamline the production process but also ensure precision, consistency, and reduced waste. By harnessing the capabilities of CNC industrial machines, enterprises can maximize their output while minimizing costs.

This blog will delve into actionable strategies that businesses can implement to fully leverage these powerful machines, from proper maintenance and programming techniques to workflow integration and employee training. By focusing on these key areas, your business can achieve a significant uplift in efficiency, ultimately leading to improved profitability and market presence.

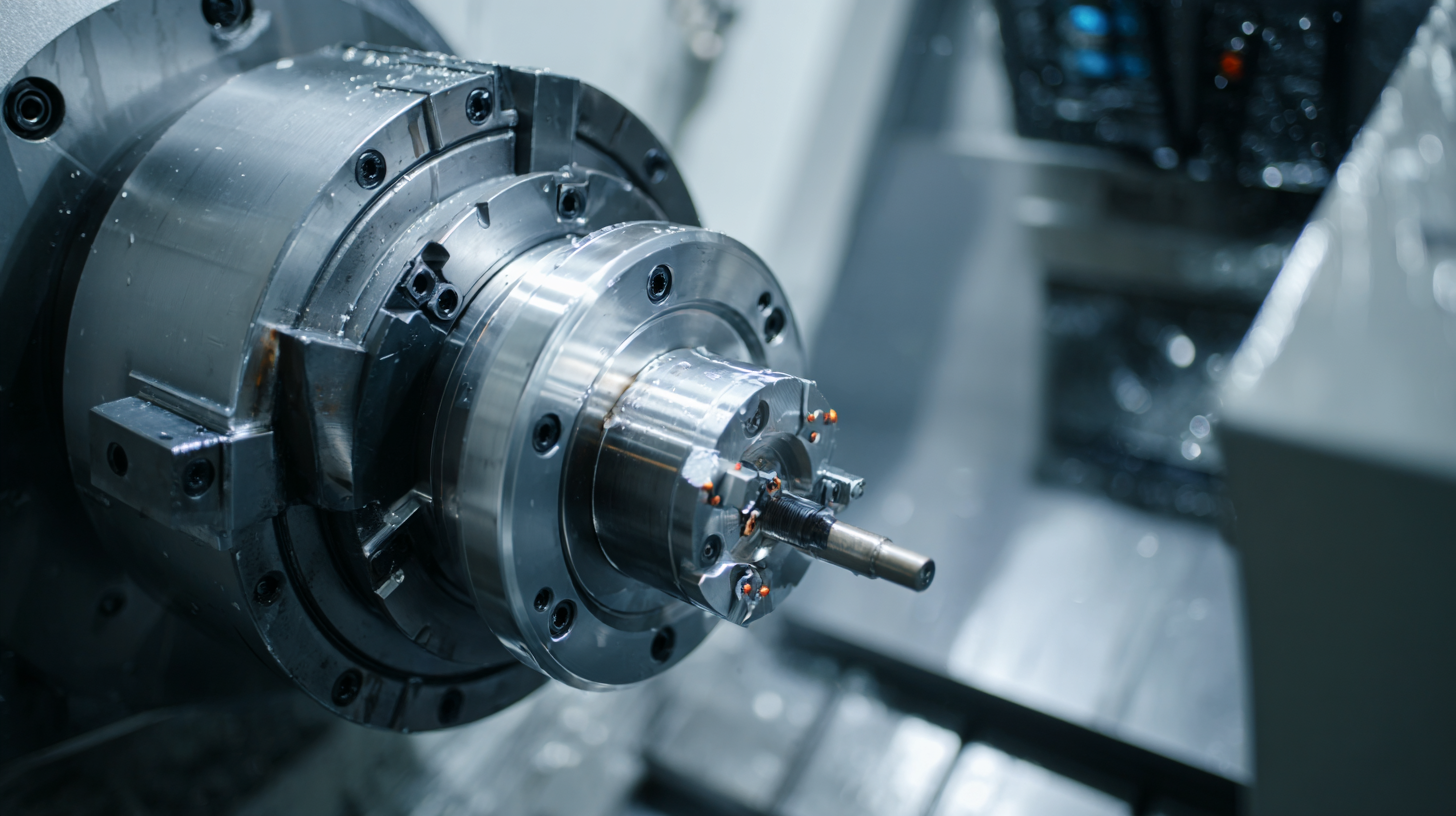

Understanding CNC Machines: Types and Their Functions

CNC machines, short for Computer Numerical Control machines, serve as critical tools in modern manufacturing, enabling precision and efficiency in various machining processes. These machines can be classified into several types, including milling, turning, and hobbing machines, each designed to perform specific tasks effectively. For instance, CNC milling machines utilize rotating multi-point cutting tools, allowing for intricate shapes and patterns. Recent advancements, such as machine learning integration for monitoring hobbing cutter health, aim to boost the effectiveness of gear manufacturing, ensuring tools are maintained for optimal performance.

Research shows that employing specific machining strategies can significantly enhance surface finish quality in wood-CNC processes, proving vital for industries focusing on aesthetic appeal and durability. Studies indicate that by optimizing feed rates and cutting depths, manufacturers can achieve lower surface roughness values, ultimately improving product quality. As the industry leans toward smarter manufacturing, the development of intelligent monitoring systems underscores the importance of data acquisition in regulating CNC machine performance. This evolution in technology not only enhances production efficiency but also promotes sustainable practices by minimizing waste and environmental impact, aligning with contemporary demands for eco-friendly manufacturing solutions.

Key Factors for Maximizing CNC Machine Efficiency

To maximize the efficiency of CNC industrial machines, businesses must focus on several key factors that significantly influence operational productivity. According to a report by the American Machinist, companies that implement structured maintenance schedules can reduce downtime by up to 30%. Regular maintenance not only extends the life of CNC machines but also ensures they operate at peak efficiency during production runs. In addition, real-time monitoring systems can alert operators to potential issues before they lead to costly machine failures.

To maximize the efficiency of CNC industrial machines, businesses must focus on several key factors that significantly influence operational productivity. According to a report by the American Machinist, companies that implement structured maintenance schedules can reduce downtime by up to 30%. Regular maintenance not only extends the life of CNC machines but also ensures they operate at peak efficiency during production runs. In addition, real-time monitoring systems can alert operators to potential issues before they lead to costly machine failures.

Another vital aspect is the optimization of tool paths. A study conducted by the Society of Manufacturing Engineers highlights that optimizing cutting parameters can lead to an increase in productivity of around 25%. This involves fine-tuning speed, feed rates, and tool selection tailored to specific materials and operations. When CNC machines are programmed with efficiency in mind, the reduction in cycle time translates directly to increased output without sacrificing quality. By incorporating these strategies, businesses can not only improve their overall production efficiency but also enhance their competitive edge in the market.

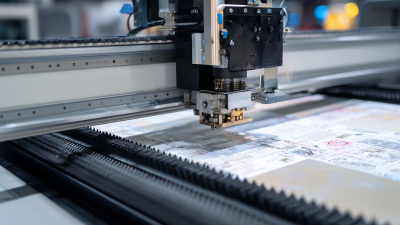

Implementing Software Solutions for Enhanced CNC Performance

Implementing software solutions can significantly enhance the performance of CNC industrial machines, leading to improved efficiency in manufacturing processes. One effective way to start is by investing in advanced CAM (Computer-Aided Manufacturing) software that seamlessly integrates with your CNC systems. This software not only optimizes tool paths but also reduces machining time, ensuring that your operations are running at maximum capacity.

- Regularly update your software to ensure compatibility with the latest CNC machines and to take advantage of new features that improve functionality.

- Consider utilizing predictive maintenance software that monitors machine health in real time, allowing you to preemptively address issues before they lead to costly downtime.

Additionally, adopting software solutions for workflow management can streamline your production schedule and enhance communication among teams. By implementing ERP (Enterprise Resource Planning) systems, you can synchronize inventory management with CNC operations, ensuring that materials are available when needed without the risk of overstocking or shortages.

- Train your staff on how to effectively use these software tools to fully leverage their capabilities for optimal performance.

- Utilize data analytics to track production metrics and identify areas for further improvement, enabling data-driven decisions that can enhance operational efficiency.

Maintenance Strategies to Improve CNC Machine Longevity

Maintaining CNC industrial machines is crucial for enhancing their longevity and optimizing operational efficiency. According to a report by the National Association of Manufacturers, regular maintenance can reduce machine downtime by up to 30%, significantly increasing productivity levels. Implementing a proactive maintenance strategy not only addresses minor issues before they escalate but also ensures that machines operate at their peak performance. Scheduled inspections and component replacements, such as bearings and cutting tools, can lead to operational efficiency improvements of 15-25%, as stated by the Society of Manufacturing Engineers.

In addition to regular inspections, adopting advanced monitoring technologies like predictive maintenance can extend the lifespan of CNC machines. Research from Deloitte indicates that predictive maintenance can result in a 10-20% reduction in maintenance costs and can prevent machine failures up to 70%. Leveraging data analytics platforms to analyze machine performance helps identify potential problems before they cause major disruptions, supporting a smoother production process. By prioritizing these maintenance strategies, businesses can ensure their CNC machines remain reliable and efficient, ultimately driving long-term success in their operations.

Training Your Workforce for Optimal CNC Operation Efficiency

In today's fast-paced manufacturing landscape, training your workforce for optimal CNC operation efficiency has never been more critical. As we move towards 2025, the integration of advanced technologies such as AI, IoT, and automation poses both challenges and opportunities. To fully leverage these innovations, companies must ensure their employees are adequately trained to use CNC machinery proficiently. This requires a shift in focus towards skill development, combining hands-on experience with digital learning platforms that cater to the evolving demands of Industry 4.0.

Moreover, as manufacturers face significant labor shortages, upskilling existing staff becomes essential. Empresas can implement customized eLearning solutions that provide immersive and scalable training for CNC operations. This approach not only addresses immediate skill gaps but also fosters a culture of continuous improvement within the workforce. By investing in training and embracing digital collaboration tools, businesses can enhance overall operational efficiency, thus positioning themselves for success in the competitive market of the future.

Optimization of CNC Machine Operation Efficiency

This chart illustrates the key metrics impacting the optimization of CNC machine operations, highlighting the importance of training hours, machine downtime, production output, and employee satisfaction for achieving high efficiency in CNC operations.

Related Posts

-

The Future of Precision Manufacturing: Advancements in CNC Milling Machines

-

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering