METROM’s

Blog

METROM’s

Blog

The Future of Precision Manufacturing: Advancements in CNC Milling Machines

As the manufacturing landscape continues to evolve, the significance of precision in production processes becomes increasingly paramount. CNC machine milling machines are at the forefront of this transformation, enhancing efficiency and accuracy in fabricating complex components across various industries. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.0% from 2020. This growth is attributed to the rising demand for high-speed machining and advancements in technology that enable greater automation and precision. As manufacturers seek to minimize waste and improve quality, CNC milling machines are integral to achieving these goals, promising a future where precision engineering is not just an advantage but a standard in production.

Technological Innovations Shaping CNC Milling Machines: A Comparative Overview

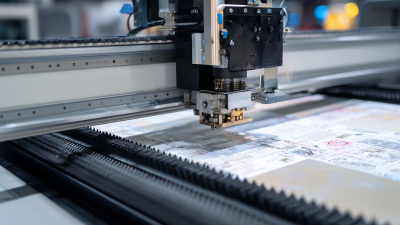

The landscape of precision manufacturing is rapidly evolving, driven by groundbreaking innovations in CNC milling machines. As industries demand higher precision and efficiency, manufacturers are investing in advanced technologies that enhance performance and adaptability. Key technological advancements include the integration of smart sensors, which provide real-time monitoring of machinery status and operational efficiency. This development not only minimizes downtime but also optimizes the entire machining process by allowing for immediate adjustments based on performance data.

Additionally, the rise of artificial intelligence in CNC milling has transformed traditional approaches to machining. AI algorithms facilitate predictive maintenance, ensuring that potential issues are addressed before they lead to costly repairs. Moreover, AI-driven software can analyze machining patterns to recommend improvements, making it possible for operators to achieve unprecedented levels of precision and repeatability. Comparing the latest CNC milling machines reveals that these technological innovations not only enhance productivity but also promote sustainability by reducing waste and energy consumption in manufacturing processes.

The Future of Precision Manufacturing: Advancements in CNC Milling Machines

This chart illustrates the advancements in CNC milling machine technology over recent years, comparing improvements in precision, speed, and efficiency.

Key Industry Statistics: CNC Milling Growth Projections and Market Trends

The CNC milling machine industry is on the cusp of remarkable growth, driven by advancements in technology and increasing demand for precision manufacturing. According to a recent industry analysis, the computer numerical control (CNC) machines market size was valued at approximately $74.9 billion in 2024 and is projected to grow at a staggering rate of 10.1%, reaching around $160.0 billion by 2032. This upward trajectory highlights the industry's response to the demand for automation and smart manufacturing solutions.

In parallel, the global machine tools market is also witnessing substantial growth. Estimated at USD 97.1 billion in 2024, it is expected to nearly double, reaching USD 196 billion by 2034, with a compounded annual growth rate (CAGR) of 7.5% from 2025. This growth encapsulates various segments, including cutting, milling, and edging machines, all of which are pivotal to the evolution of manufacturing processes. These statistics underscore the critical impact that precision machining technologies have on industries seeking efficiency and enhanced production capabilities.

The Future of Precision Manufacturing: Advancements in CNC Milling Machines

| Year | Global Market Size (USD Billion) | CNC Milling Machine Sales (Units) | Annual Growth Rate (%) | Key Application Areas |

|---|---|---|---|---|

| 2023 | 12.5 | 250,000 | 5.5 | Aerospace, Automotive, Electronics |

| 2024 | 13.2 | 275,000 | 5.6 | Aerospace, Defense, Medical |

| 2025 | 14.0 | 300,000 | 5.8 | Automotive, Electronics, Tooling |

| 2026 | 14.8 | 325,000 | 6.0 | Medical, Aerospace, Energy |

| 2027 | 15.5 | 350,000 | 6.3 | Tooling, Automotive, Manufacturing |

Evaluating CNC Milling Machine Accuracy: Traditional vs. Latest Models

In the realm of precision manufacturing, the accuracy of CNC milling machines plays a critical role in achieving high-quality outputs. Traditional CNC milling machines, while reliable, often come with limitations in terms of precision. Factors such as mechanical wear, thermal expansion, and outdated software can introduce variances that affect the final product. As manufacturers look to optimize production processes, understanding the discrepancies in accuracy between older models and the latest advancements becomes essential.

Recent advancements in CNC milling technology have significantly improved machining accuracy. Newer models are equipped with advanced sensors and real-time feedback systems that allow for immediate adjustments during the milling process. For instance, enhanced control algorithms can minimize the impact of external factors, ensuring that the machine maintains its precision even under varying operational conditions. Additionally, innovations in materials and design have led to more stable structures, further reducing the chances of error.

Moreover, the integration of artificial intelligence and machine learning in modern CNC milling machines has transformed how accuracy is evaluated and maintained. These technologies can analyze historical data to predict wear patterns and inform preventive maintenance, ensuring that machines operate at optimal performance levels. As manufacturers continue to adopt these latest models, the evolution of CNC milling towards greater precision is paving the way for more efficient and reliable manufacturing processes across various industries.

Cost Efficiency in Precision Manufacturing: Comparing CNC Milling Techniques

In the realm of precision manufacturing, the efficiency of CNC milling techniques plays a pivotal role in determining production costs. Recent advancements, particularly in the realm of collaborative optimization, have introduced methods that enhance multi-stage machining parameters, significantly impacting industries like aerospace where precision is imperative. By focusing on error propagation during machining processes, manufacturers can fine-tune their CNC operations to achieve higher output quality at reduced costs.

Additionally, the integration of AI into CNC machining is reshaping traditional manufacturing paradigms. This next-gen technology not only enhances precision but also streamlines workflows, driving down operational expenses. As CNC machines embrace automation, they are becoming increasingly capable of delivering complex tasks with minimal human intervention, further improving cost efficiency. The emergence of digital twins in CNC environments also underscores the importance of merging real and digital realms, enabling manufacturers to simulate and predict outcomes, thus minimizing waste and optimizing resources. These innovations are set to redefine precision manufacturing, making it not only more effective but also more economically viable.

Future Trends in CNC Milling Technology: Automation and AI Integration

The integration of automation and artificial intelligence (AI) in CNC milling technology is reshaping the landscape of precision manufacturing. As we approach 2025, the shift towards digital transformation is becoming increasingly pivotal. Manufacturers are leveraging advanced automation to enhance efficiency, reduce human error, and improve overall production quality. IoT-enabled equipment allows for real-time monitoring and data collection, facilitating smarter decision-making and streamlined operations. This technological evolution promises to elevate the precision of CNC milling machines, making them more adaptable to complex machining tasks.

In addition to automation, AI integration is set to revolutionize CNC milling processes. With AI-driven insights, manufacturers can predict maintenance needs, optimize machining parameters, and even implement adaptive learning algorithms to enhance machining precision over time. The anticipated growth in the metal machining market—expected to reach significant figures in the coming years—underscores the urgency for businesses to adopt these technologies. As industries like oil and gas drive this demand, the focus is squarely on harnessing cutting-edge advancements to meet market needs and stay competitive in a rapidly evolving landscape.

Related Posts

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

Unwavering Quality and Reliability of China's Best Precision CNC Milling Machines for Global Buyers

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets