METROM’s

Blog

METROM’s

Blog

What is the Future of CNC Machine 3D Printer Technology

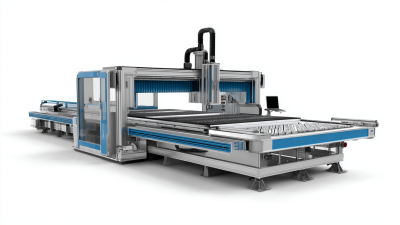

The realm of manufacturing is experiencing a significant transformation, particularly with the advent of CNC machine 3D printer technology. According to a report by MarketsandMarkets, the global 3D printing market is poised to reach $34.8 billion by 2026, growing at a compounded annual growth rate (CAGR) of 23% from 2021. This surge is largely driven by advancements in CNC (Computer Numerical Control) technologies, which enhance precision and efficiency in additive manufacturing processes. As industries from aerospace to healthcare increasingly adopt these innovations, the integration of CNC machine 3D printers is set to redefine production standards, reduce material waste, and enable the creation of complex geometries that were previously unattainable. This blog will explore the future potential of CNC machine 3D printer technology, examining emerging solutions and their implications for various sectors.

Emerging Trends in CNC Machine 3D Printing Technology

The future of CNC machine 3D printing technology is bright, with several emerging trends poised to redefine the landscape of manufacturing. A key trend is the increasing focus on sustainability, as companies strive to lower their carbon footprints. By 2030, the 3D printing industry is expected to surpass $40 billion in value, driven by enhanced adoption across various sectors. This surge is complemented by efforts to strengthen supply-chain resilience, indicative of the industry's adaptability in facing global challenges.

As we approach 2025, the integration of advanced automation, IoT-enabled equipment, and AI-driven insights will revolutionize industrial machine design. For instance, the shift towards modularity allows manufacturers to craft more efficient and customizable solutions. Companies that leverage these innovations can significantly reduce material wastage—a critical consideration in the age of environmental accountability.

Tips:

1. Embrace digital transformation in your manufacturing processes to stay competitive and optimize resource utilization.

2. Keep an eye on additive manufacturing trends to explore new materials and methods that can enhance your product designs.

3. Invest in training your team on the latest technologies like AI and IoT, which are essential for driving innovation in machine design.

Key Innovations Driving the Future of CNC 3D Printers

The future of CNC machine 3D printer technology is being shaped by remarkable innovations that are redefining manufacturing capabilities. Recent advancements in 3D printing for polymer composites position this technology at the forefront, enhancing the strength and versatility of printed materials. These composites allow for the production of lightweight yet durable structures, empowering industries ranging from aerospace to automotive. This evolution not only improves performance but also significantly reduces waste during the manufacturing process, which aligns with the growing emphasis on sustainability.

Moreover, the integration of 3D printing in diverse fields like healthcare and food production indicates a shift toward more personalized solutions. The creation of physical organ models demonstrates the potential of 3D printing in medical applications, paving the way for tailored surgical procedures. Similarly, advancements in food printing technology facilitate the customization of nutrition, reflecting changing consumer demands. As the industry continues to evolve, the collaboration between CNC machinery and 3D printing technologies will likely lead to unprecedented advancements, unlocking further efficiencies and new applications across various sectors.

What is the Future of CNC Machine 3D Printer Technology - Key Innovations Driving the Future of CNC 3D Printers

| Innovation | Description | Potential Impact | Estimated Adoption Year |

|---|---|---|---|

| Hybrid Manufacturing | Combines traditional CNC machining with additive printing for increased flexibility. | Enhanced production efficiency and reduced material waste. | 2025 |

| AI Integration | Utilizes machine learning algorithms for predictive maintenance and optimization. | Lower operational costs and improved machine uptime. | 2024 |

| Smart Materials | Materials that can change properties in response to environmental factors. | Broader application possibilities in medical and aerospace industries. | 2026 |

| Cloud-Based Management | Remote monitoring and management of CNC processes via the cloud. | Improved scalability and collaboration among teams. | 2023 |

| Sustainable Practices | Focus on recycling materials and reducing energy consumption. | Contributes to environmental responsibility and cost savings. | 2027 |

Top Strategies for Enhancing Precision in CNC 3D Printing

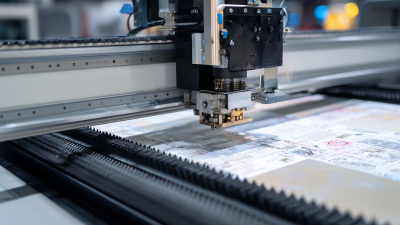

As the landscape of CNC machine 3D printing evolves, enhancing precision remains a crucial focus for manufacturers striving for flawless production. One effective strategy involves implementing advanced feedback control systems that provide real-time data during the printing process. Such systems can dynamically adjust parameters, ensuring optimal laser power and speed in processes like laser powder bed fusion. This advancement not only improves the quality of printed parts but also increases overall efficiency by minimizing material waste.

Furthermore, targeted surface modification techniques can significantly improve the integration of new materials in 3D printing. For instance, approaches that enhance the roughness and texture of printed parts lead to better adhesion and interfacial strength, which are critical for creating composite materials. By leveraging innovative strategies in both hardware and material science, manufacturers can push the boundaries of precision in CNC 3D printing, ultimately driving growth in a market projected to reach substantial figures over the next decade. These developments promise a more competitive edge for industries, especially in regions like Asia Pacific, where demand for advanced machine tools is set to rise sharply.

Sustainable Practices in CNC Machining and 3D Printing

As the world moves towards more sustainable manufacturing practices, CNC machining and 3D printing technology are evolving to meet these environmental demands. Eco-friendly materials and energy-efficient processes are being prioritized, leading to reduced waste and lower carbon footprints. By embracing these sustainable practices, industries can not only minimize their environmental impact but also appeal to a growing demographic of environmentally conscious consumers.

Tip 1: Consider utilizing biodegradable and recyclable materials when designing prototypes or final products. This will not only reduce waste but also enhance your brand’s reputation as a sustainability leader.

Moreover, the integration of advanced CNC machinery with 3D printing allows for a more efficient production process. By combining these technologies, manufacturers can create complex designs with less material, thereby streamlining operations and further promoting sustainability. Adopting digital fabrication techniques enables real-time adjustments, minimizing excess output and energy consumption.

Tip 2: Invest in energy-efficient CNC machines and 3D printers equipped with smart technology that optimizes power usage during production. This not only cuts costs but also contributes to an overall greener operation.

How to Adapt CNC 3D Printing for Various Industries

As CNC machine 3D printer technology continues to evolve, its adaptability for various industries becomes increasingly critical. The inherent precision and efficiency of CNC 3D printing allow manufacturers to tailor components specifically for their needs, reducing material waste and production time. For instance, in the aerospace sector, individualized parts can be designed and manufactured with intricate geometries, significantly enhancing performance and safety. The flexibility of CNC machines merges with additive manufacturing capabilities, enabling the creation of lightweight components without sacrificing strength.

In the medical field, the customizability of CNC 3D printer technology opens up new possibilities for personalized solutions. Prosthetics and implants can be designed based on a patient’s unique anatomy, improving both comfort and functionality. Furthermore, industries like automotive and construction can also leverage these advancements for rapid prototyping, allowing for more innovative designs and quicker adjustments during the production process. By integrating this technology into their workflows, businesses can stay competitive and responsive to market demands, demonstrating the transformative potential of CNC machine 3D printing across various applications.

Related Posts

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

Unwavering Quality and Reliability of China's Best Precision CNC Milling Machines for Global Buyers