METROM’s

Blog

METROM’s

Blog

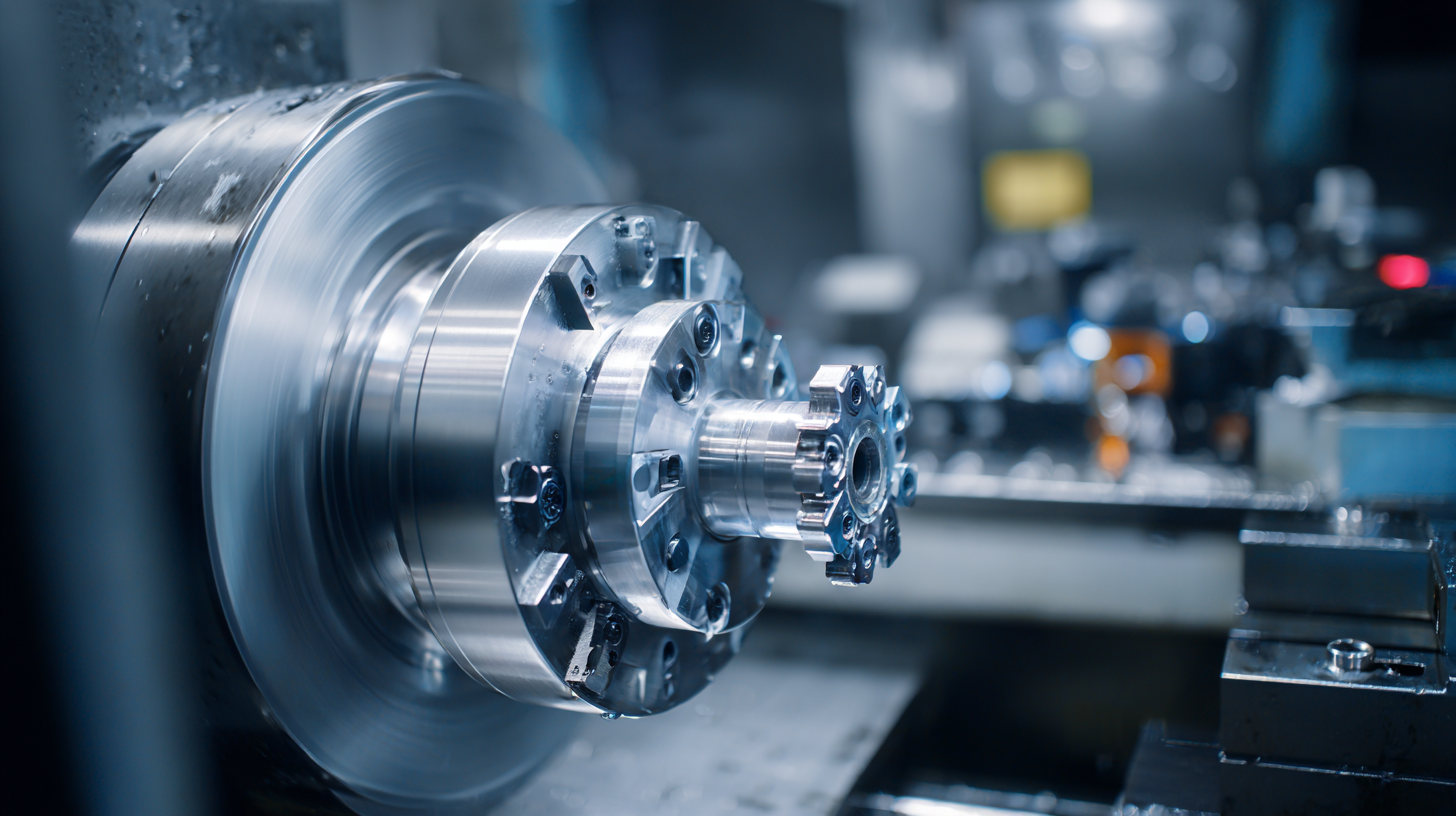

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

In the realm of global manufacturing, excellence in CNC machining has become a cornerstone for competitive advantage and innovation. As reported by MarketsandMarkets, the CNC machine tools market is projected to reach $100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.0% from 2020. This increase is driven by the growing demand for precision machining across various industries, including automotive, aerospace, and medical equipment.

With the rise of Industry 4.0, the integration of smart technologies is further enhancing the capabilities of CNC machines, leading to significant improvements in productivity and efficiency. However, as this sector expands, the importance of adhering to industry import and export certifications becomes crucial. Understanding the regulatory landscape is essential for businesses looking to navigate the complexities of international trade and capitalize on the opportunities presented by the evolving CNC machine industrial landscape.

With the rise of Industry 4.0, the integration of smart technologies is further enhancing the capabilities of CNC machines, leading to significant improvements in productivity and efficiency. However, as this sector expands, the importance of adhering to industry import and export certifications becomes crucial. Understanding the regulatory landscape is essential for businesses looking to navigate the complexities of international trade and capitalize on the opportunities presented by the evolving CNC machine industrial landscape.

The Evolution of CNC Machining: From Local to Global Solutions

The evolution of CNC machining has significantly transformed from local workshops to a global manufacturing powerhouse. Initially, CNC (Computer Numerical Control) machines were limited to small-scale operations, catering to regional markets with specialized needs. These early implementations provided businesses with increased precision and efficiency compared to traditional machining.

As globalization progressed, CNC machining became integral to industries across the globe. Companies recognized the value of outsourcing production to regions with lower labor costs while maintaining high-quality standards through CNC technology. The ability to remotely operate and monitor machines has enabled manufacturers to efficiently produce components and products tailored to international specifications.

Moreover, the integration of smart technologies, such as IoT and AI, is propelling CNC machining into the future, facilitating real-time data analysis and enhancing decision-making. This evolution not only signifies a leap in operational capabilities but also underscores the importance of CNC machining in supporting a diverse and interconnected global economy.

Quality Standards in CNC Machining: Ensuring Consistency Across Borders

In today's global manufacturing landscape, maintaining quality standards in CNC machining is paramount for ensuring consistency across borders. With different countries implementing their own regulations and practices, a unified approach is essential. Innovations like blockchain technology are paving the way for smoother cross-border transactions, particularly in sectors such as carbon emissions trading, where consistency and data protection are crucial.

Tips for achieving quality across borders include understanding and integrating international standards such as ISO in your operations. This establishes a framework for your processes and products, ensuring they meet the expected criteria regardless of location. Additionally, invest in training your workforce on these standards to foster a culture of quality that transcends geographical boundaries.

Collaboration with global partners can also enhance quality assurance. By sharing best practices and resources, businesses can mitigate risks associated with inconsistencies. Regular audits and improvements based on feedback will help sustain high-quality outcomes, benefiting not only your organization but also contributing positively to the global manufacturing ecosystem.

Innovative Technologies Driving CNC Machining Excellence

Innovative technologies are revolutionizing the CNC machining industry, elevating it to new heights of precision and efficiency. The integration of advanced automation and artificial intelligence is at the forefront of this transformation, allowing for real-time monitoring and optimization of machining processes. These technologies not only reduce downtime but also enhance accuracy, ensuring that components meet stringent quality standards essential for global manufacturing.

Moreover, the introduction of additive manufacturing techniques alongside traditional CNC machining offers a hybrid approach that expands design possibilities. This synergy enables manufacturers to produce complex geometries that would be impossible to achieve with conventional methods alone. As advancements in materials science emerge, CNC machining is becoming increasingly versatile, accommodating a wider range of materials, including advanced composites and metals. The continuous evolution of these innovative technologies is paving the way for unmatched manufacturing excellence in a highly competitive global market.

The Role of Skilled Workforce in Advancing CNC Manufacturing

In the rapidly evolving landscape of CNC machining, the critical role of a skilled workforce cannot be overstated. As industries seek to leverage advanced technologies and high-precision tools, the need for workers adept in both the design and operation of CNC machinery has surged. Programs aimed at bridging skill gaps through enhanced vocational training are becoming essential, particularly as manufacturers strive for efficiency and excellence in production. The introduction of accelerated training initiatives not only addresses the immediate workforce deficiency but also prepares a new generation of skilled laborers ready to tackle the complexities of modern manufacturing.

Take the Brooklyn Navy Yard, for instance, where a dedicated investment in CNC training reflects a proactive approach to meet the burgeoning demand for skilled operators. Such initiatives are crucial for revitalizing local manufacturing sectors and ensuring that businesses have access to the talent needed to thrive in a competitive global market. By focusing on the importance of education and skill development, we can cultivate a workforce equipped to advance CNC manufacturing, ensuring the longevity and success of the industry on a global scale.

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

This chart illustrates the relationship between skilled workforce availability and CNC machining output efficiency across various regions.

Building Trust: How Chinese Factories Lead in Global Manufacturing Quality

In the competitive landscape of global manufacturing, Chinese factories have positioned themselves as leaders by consistently delivering high-quality products through advanced CNC machining techniques. These facilities capitalize on cutting-edge technology and skilled labor, seamlessly integrating precision with efficiency. By prioritizing quality control processes and adopting international standards, they not only meet but exceed the expectations of their global clients, fostering a reputation that resonates across various industries.

Building trust is essential for sustainable partnerships in manufacturing. Chinese manufacturers understand that reliability and transparency are key factors that influence client retention. By investing in robust quality assurance practices and maintaining open lines of communication, these factories cultivate long-term relationships with their partners. Clients can rest assured that their specifications will be met with utmost diligence, leading to more collaborative and innovative solutions that benefit all parties involved.

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

| Dimension | Metric | China's Position | Global Average |

|---|---|---|---|

| CNC Machining Precision | ±0.01 mm | 95% | 85% |

| Delivery Time | 2 weeks | 90% | 75% |

| Defect Rate | 1% | High Standard | 3% |

| Technology Adoption | Advanced | 80% | 65% |

| Customer Satisfaction | Score 90/100 | 94% | 80% |