METROM’s

Blog

METROM’s

Blog

Why Are Manufacturing Machines Essential for Modern Industry?

In today's fast-paced world, manufacturing machines play a crucial role in modern industry. These machines increase efficiency and productivity. They are integral to various sectors, from automotive to electronics. However, their use raises questions about reliability and skill requirements.

Manufacturing machines are not just tools. They are essential for meeting consumer demands. With precision and speed, these machines create high-quality products. Yet, dependence on technology can lead to challenges. Companies must invest in training workers to operate these complex systems.

As industries evolve, so do manufacturing machines. They are becoming smarter and more efficient. However, this evolution comes with risks. Companies must balance automation benefits with human oversight. This ongoing challenge highlights the need for reflection on our reliance on technology.

The Role of Manufacturing Machines in Streamlining Production Processes

Manufacturing machines play a crucial role in modern production. They increase efficiency and reduce human error. Workers benefit from automation, but it also raises concerns. As machines take over repetitive tasks, job displacement occurs. Companies must address training needs for affected employees.

In a factory, machines streamline various processes. They can cut, assemble, or package products with precision. This automation allows for faster production cycles. Products can move from concept to completion quickly. However, reliance on technology also presents challenges. Machines can malfunction, leading to downtime and lost revenue.

Innovation is essential to keep up with market demands. Yet, over-reliance on machines may stifle creativity. Employees might feel less engaged in their roles. Therefore, a balance is needed between machinery and human input. Continuous improvement in both areas will drive success.

Manufacturing Machines' Contribution to Production Efficiency

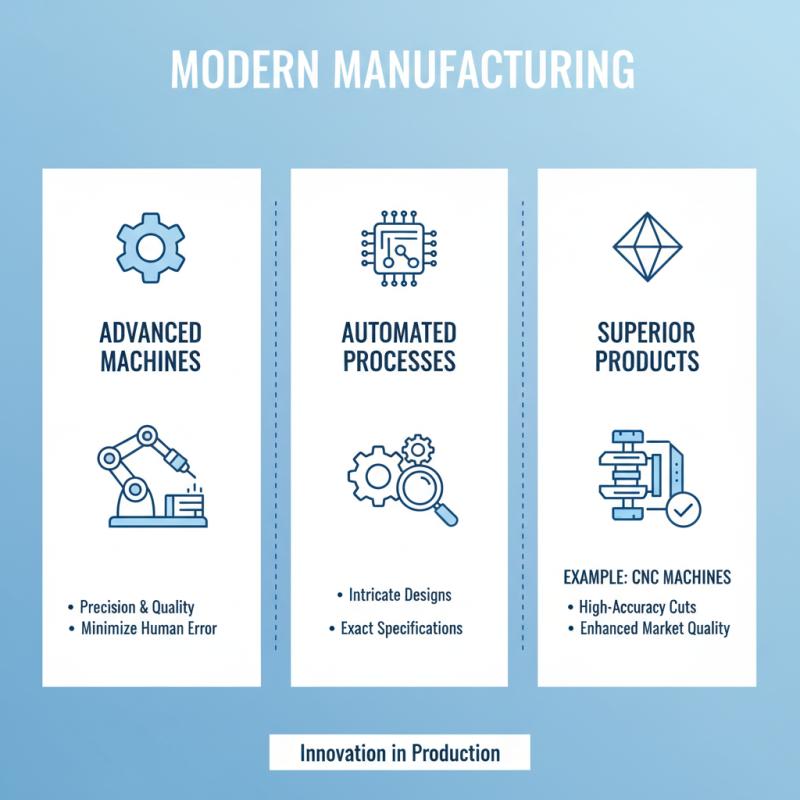

Enhancing Precision and Quality Control Through Advanced Machinery

Modern manufacturing relies heavily on advanced machines to improve precision and quality control. These machines are designed to minimize human error. With automated processes, manufacturers can achieve intricate designs that meet exact specifications. Such detail can improve the final product significantly. For instance, CNC machines offer high accuracy for complex cuts. This precision directly translates to better quality products on the market.

**Tip:** Invest in training sessions for your operators. Proper understanding of advanced machinery enhances efficiency. When operators are well-informed, they can troubleshoot issues quickly. This minimizes downtime and maintains quality standards.

However, modern machinery isn’t without its challenges. Maintenance can be costly and time-consuming. Regular checks are essential to prevent breakdowns. A sudden malfunction can dramatically affect production schedules. It’s crucial to have contingency plans in place. Always be ready to adapt to unforeseen circumstances.

**Tip:** Keep a logbook for machine performance. It helps track patterns over time. This can identify potential issues before they escalate. Regular reviews may lead to improvement in maintenance schedules.

Economic Impact of Automated Machines on Modern Industries

Manufacturing machines play a crucial role in modern industries. They enhance productivity and reduce costs. Automated machines streamline operations, improving efficiency drastically.

For example, robotic arms can assemble products faster than human workers. This shift allows companies to increase output without requiring additional labor.

The economic impact of these machines is significant. They create jobs in new sectors, like machine maintenance and programming. However, some traditional jobs may disappear. Workers need to adapt to new technologies.

Upskilling is essential for staying relevant in the job market.

Tips: Embrace learning new skills. Explore online courses related to manufacturing technology. Network with professionals in the field. Keep an eye on trends in automation. This can guide your career path and make you more adaptable.

The Evolution of Manufacturing Machines and Their Technological Advances

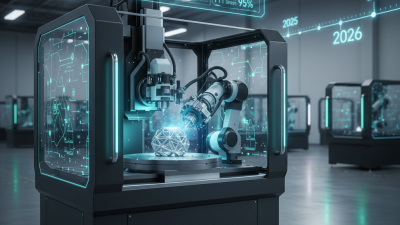

The evolution of manufacturing machines has significantly shaped modern industry. Over the past few decades, these machines have become more sophisticated. Reports show that global industrial automation is expected to grow steadily, potentially reaching $214 billion by 2026. This growth indicates a shift towards more efficient production processes.

Innovations in robotics and artificial intelligence play a crucial role in this transformation. Modern machines can now perform complex tasks with minimal human intervention. For instance, collaborative robots, or cobots, can safely work alongside humans, enhancing productivity. However, not all industries have adopted these technologies at the same pace. Some sectors still rely on outdated machinery, missing out on increased efficiency and cost savings.

Challenges remain in integrating new technologies. This transition requires workforce retraining and investment in infrastructure. Moreover, the risk of job displacement raises ethical concerns. As industries modernize, there are critical conversations about the future of work. Ultimately, while manufacturing machines have evolved, balancing technology with human employment remains a complex issue.

Why Are Manufacturing Machines Essential for Modern Industry?

| Dimension | Data |

|---|---|

| Types of Manufacturing Machines | CNC Machines, 3D Printers, Industrial Robots, Injection Molding Machines, Laser Cutters |

| Advantages of Automation | Increased Efficiency, Higher Precision, Reduced Labor Costs, Enhanced Safety |

| Industry Sectors Utilizing Machines | Automotive, Aerospace, Electronics, Consumer Goods, Food Production |

| Important Technological Advances | IoT Integration, AI and Machine Learning, Advanced Materials, Energy Efficiency Technologies |

| Projected Growth of Manufacturing Automation | 25% increase in automation adoption by 2025 |

Sustainability and Efficiency: The Future of Manufacturing Equipment

Manufacturing machines play a critical role in enhancing efficiency and sustainability in modern industries. Advanced equipment reduces waste and optimizes resource usage. For instance, machines equipped with sensors can monitor energy consumption. This allows for adjustments to minimize costs and environmental impact. Companies can drastically lower their carbon footprint by using smart technology.

Tips: Regular maintenance checks can help you save on energy costs. Small adjustments in machine operation can lead to significant savings over time.

To boost sustainability, manufacturers should invest in innovative technologies. Machines that recycle materials or use renewable energy sources are gaining popularity. However, not all equipment meets these criteria. Analyzing your current machines may reveal areas for improvement. Upgrading older machines can be a step towards a greener future.

Tips: Set realistic goals for your sustainability journey. Measure your energy use and waste regularly to identify progress. Small changes can lead to big results over time.

Related Posts

-

How to Choose the Right Manufacturing Machines for Your Production Needs

-

Discovering Industrial Machine Innovations at China Import and Export Fair 2025

-

China Craftsmanship in Milling Machines Elevating Global Standards and Sales Success

-

Top CNC Machines to Watch in 2026 What Makes Them Stand Out?

-

Strategies for Sourcing the Best Milling Machine Tools in the Market Analysis of 2025

-

Unleashing Global Trust Through Excellence in CNC Cutting Machines from China's Leading Factories