METROM’s

Blog

METROM’s

Blog

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

In the rapidly evolving landscape of manufacturing, industrial CNC machines have emerged as

indispensable tools that drive efficiency and precision across various sectors.

According to a report by ResearchAndMarkets, the global CNC machine market

is anticipated to reach USD 100 billion by 2025, driven largely by advancements in

automation technologies and increasing demand for

high-quality production outputs. This comprehensive comparison

of the top industrial CNC machines for global buyers will explore the latest trends

and innovations, as well as delve into solutions tailored for specific machine types.

As industries strive for greater competitiveness

in a globalized market, understanding the capabilities and specifications of these machines is

crucial for manufacturers aiming to enhance their operational efficiency and

product quality.

In the rapidly evolving landscape of manufacturing, industrial CNC machines have emerged as

indispensable tools that drive efficiency and precision across various sectors.

According to a report by ResearchAndMarkets, the global CNC machine market

is anticipated to reach USD 100 billion by 2025, driven largely by advancements in

automation technologies and increasing demand for

high-quality production outputs. This comprehensive comparison

of the top industrial CNC machines for global buyers will explore the latest trends

and innovations, as well as delve into solutions tailored for specific machine types.

As industries strive for greater competitiveness

in a globalized market, understanding the capabilities and specifications of these machines is

crucial for manufacturers aiming to enhance their operational efficiency and

product quality.

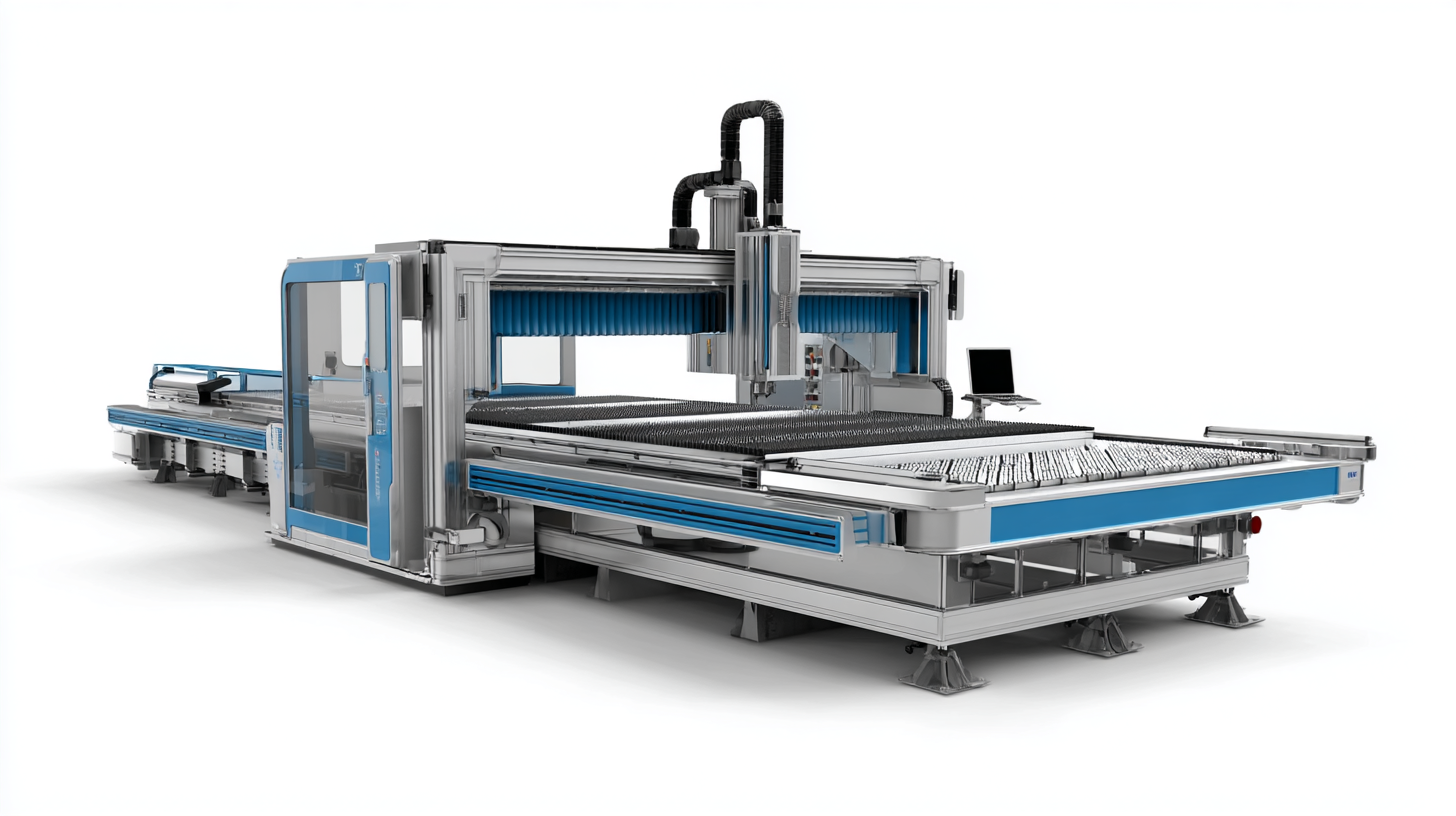

Key Features of Industrial CNC Machines: What to Consider

When considering industrial CNC machines, it's essential to focus on key features that cater to the specific needs of various manufacturing environments. High-precision capabilities are critical for achieving the detailed craftsmanship required in modern industry. Buyers should evaluate the machine's accuracy, repeatability, and the types of materials it can handle, as these factors significantly impact production efficiency and output quality. Additionally, the integration of user-friendly interfaces and advanced software for programming can streamline operations, making it easier for workers to optimize their processes.

Another important aspect to consider is the machine's adaptability to future technological advancements. As industries evolve, so too should the equipment that powers their processes. The compatibility of CNC machines with emerging technologies, such as automation and artificial intelligence, can enhance productivity and reduce downtime. Furthermore, understanding the competitive landscape, including market share and growth predictions, can guide buyers in selecting machines that not only meet current demands but also position them strategically for future challenges in the market.

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

| Machine Type | Max Working Area (mm) | Spindle Speed (RPM) | Tool Change Type | Price Range (USD) | Materials Compatible |

|---|---|---|---|---|---|

| CNC Milling Machine | 1200 x 800 x 600 | 24000 | Automatic | 50,000 - 100,000 | Aluminium, Plastic, Wood |

| CNC Laser Cutter | 3000 x 1500 | 20000 | Manual | 30,000 - 70,000 | Metal, Acrylic, Wood |

| CNC Router | 2400 x 1200 | 18000 | Automatic | 25,000 - 60,000 | Wood, Composite, Plastic |

| CNC Plasma Cutter | 4000 x 2000 | 15000 | Automatic | 20,000 - 50,000 | Metal |

Top Industrial CNC Machines: A Detailed Specification Comparison

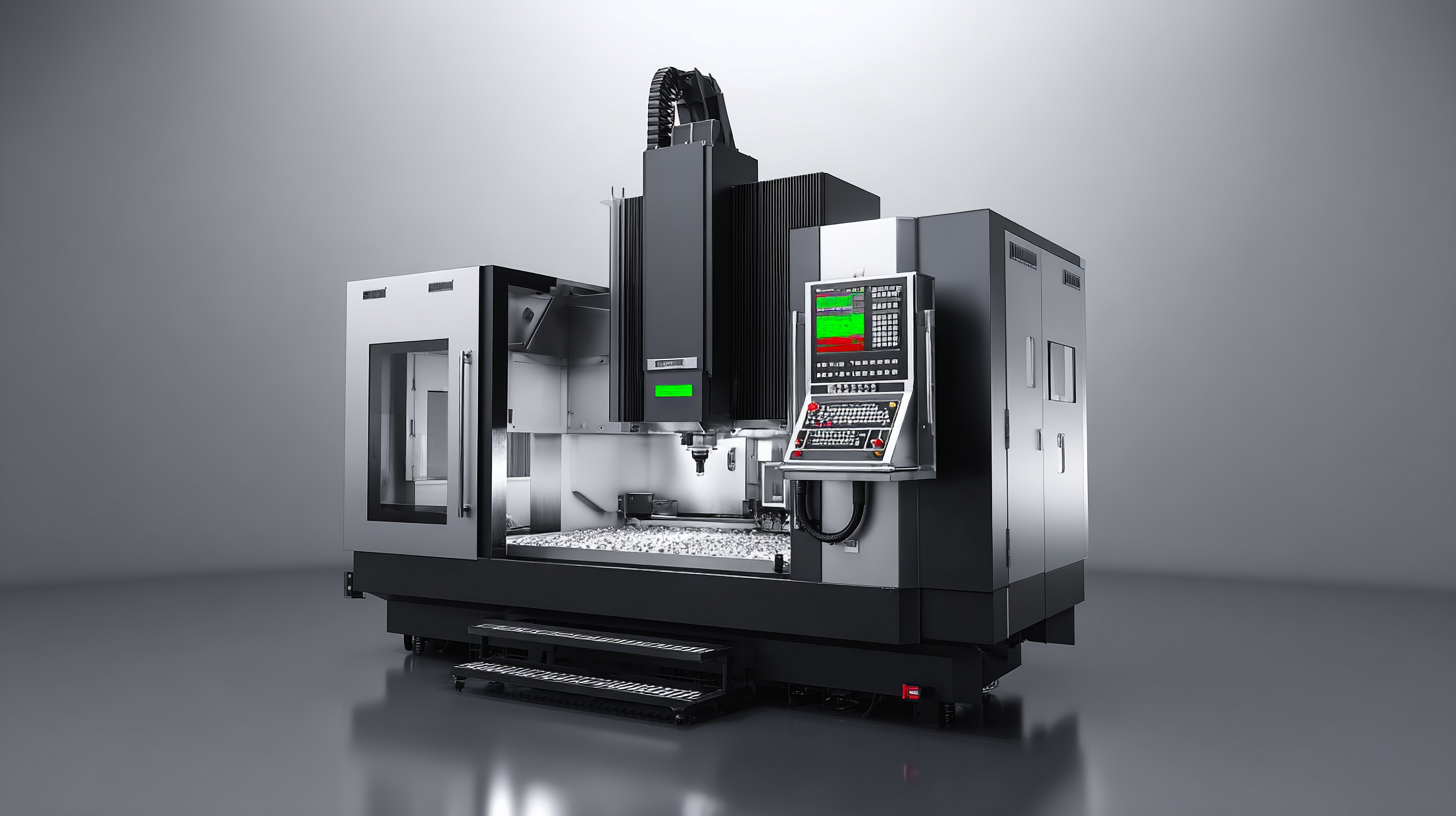

When considering the best industrial CNC machines on the market, a detailed specification comparison becomes essential for global buyers. This analysis not only helps in understanding the core functionalities but also highlights the key differences that can influence investment decisions. Key specifications to focus on include precision, speed, and versatility of the machines. For instance, while some CNC machines excel in high-speed milling, others are designed with enhanced precision for intricate designs.

When considering the best industrial CNC machines on the market, a detailed specification comparison becomes essential for global buyers. This analysis not only helps in understanding the core functionalities but also highlights the key differences that can influence investment decisions. Key specifications to focus on include precision, speed, and versatility of the machines. For instance, while some CNC machines excel in high-speed milling, others are designed with enhanced precision for intricate designs.

Additionally, buyers should evaluate the software capabilities paired with the CNC machines. Advanced software integration allows for better control over machining processes, reducing errors and increasing productivity. Other factors, such as machine size, weight, and energy efficiency, also play a critical role in the decision-making process. By analyzing these specifications, global buyers can choose the best CNC machine that caters to their specific manufacturing needs, ensuring they stay competitive in an ever-evolving industrial landscape.

Price vs. Performance: Evaluating Cost-Effectiveness in CNC Machines

When evaluating CNC machines for industrial applications, the balance between price and performance is critical. Buyers are often faced with the challenge of selecting a machine that not only fits their budget but also meets their production needs. High-quality machines may come with a steep price tag, but they often offer superior accuracy, durability, and features that can enhance productivity in the long run. In contrast, budget-friendly options may result in higher operating costs due to repairs, maintenance, and wasted materials, ultimately affecting the bottom line.

Performance metrics such as spindle speed, feed rate, and the range of materials a machine can handle are essential to consider. A cost-effective CNC machine should provide a good return on investment, which means it should be efficient in producing high-quality outputs. Evaluating multiple options based on their specifications and client reviews is vital for making an informed decision. Assessing the long-term cost implications of ownership, rather than just the initial purchase price, allows buyers to choose the right CNC machine that aligns with their operational goals and budget constraints.

User Reviews and Feedback: Insights on the Best CNC Options

When it comes to selecting the best CNC machines, the experiences of actual users can provide invaluable insights. User reviews often highlight not only the operational effectiveness of the machines but also their reliability and ease of use. For instance, many buyers have praised a particular model for its precision and speed, which are critical in industries where time equals money. Additionally, reviews frequently discuss the availability of customer support and how responsive manufacturers are to inquiries and technical issues, a factor that significantly influences the overall satisfaction of the user.

Furthermore, feedback from users often reflects a variety of applications, showcasing how different CNC machines perform across diverse industries like aerospace, automotive, and manufacturing. Some reviews detail personalized modifications or upgrades that users implemented to enhance performance, emphasizing the machine’s versatility. This kind of firsthand experience not only helps prospective buyers make informed decisions but also encourages manufacturers to innovate and improve their offerings based on user suggestions and critiques. Thus, diving into user feedback is essential for anyone looking to invest in a CNC machine that balances quality, functionality, and support.

Future Trends in CNC Technology: What Buyers Need to Know

As technology continues to evolve, the landscape of CNC (Computer Numerical Control) machinery is transforming at a rapid pace. For buyers looking to invest in industrial CNC machines, understanding future trends is crucial to making informed decisions. One significant trend is the integration of AI and machine learning, which enhances the precision and efficiency of CNC machining processes. By leveraging these technologies, manufacturers can optimize production schedules and reduce waste, ultimately leading to cost savings.

Tip: When considering a CNC machine, look for models that incorporate smart technology features. These advancements can provide real-time data and predictive maintenance alerts, which are invaluable for streamlining operations.

Another important trend is the shift towards more sustainable practices within the CNC industry. As environmental consciousness grows, manufacturers are increasingly focused on producing energy-efficient machines that minimize their carbon footprint. Buyers should prioritize models that offer eco-friendly features, including reduced energy consumption and biodegradable lubricants.

Tip: Research manufacturers that are committed to sustainability in their production processes. Eco-friendly practices not only contribute to the planet's well-being but can also enhance your company's reputation in an increasingly competitive market.