METROM’s

Blog

METROM’s

Blog

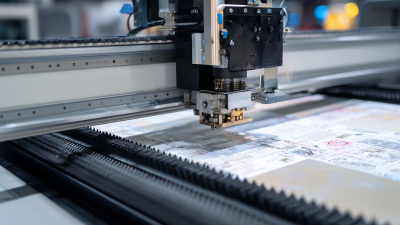

Unlocking Precision: How CNC Milling Machines Drive Efficiency in Modern Manufacturing Industry

In the rapidly evolving landscape of modern manufacturing, the adoption of advanced technologies is paramount for achieving unparalleled efficiency and precision. Central to this transformation is the CNC machine milling machine, which has revolutionized production processes across various industries. According to a report by the International Federation of Robotics, CNC machines are expected to account for over 60% of the automated machinery market by 2025, highlighting their crucial role in enhancing productivity. Additionally, a study by Deloitte indicates that companies leveraging CNC milling technology have experienced up to a 30% reduction in operational costs, underscoring the economic benefits of such machinery. As manufacturers seek to optimize their supply chains and improve product quality, the CNC machine milling machine stands out as a key driver of innovation and efficiency in today's competitive market.

The Role of CNC Milling Machines in Streamlining Production Processes

CNC milling machines play a crucial role in streamlining production processes within the modern manufacturing industry. By providing unparalleled precision and automation, these machines significantly enhance productivity and efficiency. The increasing demand for precise manufacturing solutions has driven robust growth in the CNC machine market, with advancements in technology enabling industries to achieve higher standards of quality and speed. Automation and AI integration further enable manufacturers to refine their processes, reducing human error and speeding up production time.

Recent investments in cutting-edge CNC technology underline its importance in contemporary manufacturing. Companies are leveraging innovative solutions such as digital twins to ensure seamless integration between virtual models and physical machines, which is essential for producing high-precision components. The evolution of hybrid manufacturing, combining traditional CNC methods with 3D printing, is another testament to how CNC machines are revolutionizing production by minimizing material waste and optimizing efficiency. As industries continue to adopt these advanced systems, the role of CNC milling machines will be pivotal in shaping the future of manufacturing.

Enhancing Precision: The Technological Advancements of CNC Milling

The technological advancements in CNC milling machines have revolutionized the modern manufacturing industry by significantly enhancing precision and efficiency. With the integration of advanced digital manufacturing technologies, manufacturers can now achieve higher levels of accuracy in their machining processes. This precision not only reduces material waste but also minimizes the time required for production, streamlining workflows across various sectors, including automotive, aerospace, and woodworking.

The woodworking CNC tools market exemplifies this trend, projected to grow from USD 8.2 billion in 2025 to USD 13.4 billion by 2035, with a compound annual growth rate (CAGR) of 5.0%. This growth reflects a broader shift within the industry towards adopting CNC technology, which enables the creation of intricate designs with remarkable consistency. Similarly, the CNC controller market is expected to expand from USD 7.2 billion in 2025 to USD 12.4 billion by 2035, underlining the increasing reliance on sophisticated CNC systems to drive manufacturing efficiency. As businesses continue to embrace these technological innovations, the landscape of modern manufacturing will undoubtedly become more competitive and productive.

Cost Efficiency: How CNC Milling Reduces Waste and Increases Profitability

In today's competitive manufacturing landscape, cost efficiency has become a critical factor for success. CNC milling machines are at the forefront of this transformation, significantly reducing waste and enhancing profitability. According to recent industry reports, the integration of advanced analytics and AI in CNC operations can lead to productivity improvements of up to 30%. By streamlining processes and minimizing scrap material, companies can not only save costs but also maximize the utilization of their resources.

Additionally, the rise of digitalization and IoT technologies has further amplified the benefits of CNC machining. Research indicates that manufacturers adopting these technologies can improve operational efficiency by as much as 20%, directly impacting their bottom line. The use of sophisticated nesting software and fabrication extensions allows for effective material management, ensuring that every piece of raw material is utilized optimally. As the manufacturing sector evolves, leveraging CNC milling not only addresses current economic pressures but also positions companies for sustainable growth and competitive advantage in the future.

Unlocking Precision: How CNC Milling Machines Drive Efficiency in Modern Manufacturing Industry

| Metric | Value | Key Benefits |

|---|---|---|

| Material Waste Reduction | 20% - 30% | Lower raw material costs and environmental impact |

| Production Speed Increase | 15% - 25% | Faster time to market and higher output |

| Energy Consumption Reduction | 10% - 15% | Lower operational costs and eco-friendly practices |

| Repair and Maintenance Costs | 5% - 10% lower | Longer machine lifespan and reduced downtime |

| Order Fulfillment Time | 20% faster | Improved customer satisfaction and loyalty |

The Impact of CNC Milling on Product Quality and Consistency

CNC milling machines have revolutionized the modern manufacturing industry by enhancing product quality and consistency. The global CNC milling market is projected to grow significantly, from an estimated value of $16,626 million in 2025 to approximately $26,699.9 million by 2033, showcasing a compound annual growth rate (CAGR) of 6.1%. This growth reflects the increasing demand for precision and efficiency in manufacturing processes. As industries adopt advanced digital manufacturing technologies, the ability to produce complex parts with high accuracy becomes paramount.

The effectiveness of CNC milling in maintaining quality is largely attributed to its automated nature, which minimizes human error and variability in product outputs. The metal processing machinery market is expected to reach $92 billion between 2024 and 2032, highlighting the substantial reliance on CNC technology for precise machining tasks. As manufacturers seek to optimize their operations, CNC machines are not just tools but essential solutions for achieving precise dimensional tolerances and superior consistency, enabling businesses to meet stringent quality standards and customer expectations in an increasingly competitive landscape.

Future Trends: The Evolving Landscape of CNC Milling in Manufacturing

The landscape of CNC milling is rapidly evolving, driven by advancements in technology and rising demand across various sectors. According to industry reports, the global CNC milling machine market is projected to reach a value of $16,626 million by 2025, with an anticipated growth to $26,699.9 million by 2033, reflecting a compound annual growth rate (CAGR) of 6.1%. This growth highlights the increasing reliance on CNC milling for precision manufacturing and efficiency optimization, making it an integral part of modern production environments.

Moreover, the desktop CNC milling machine market is also witnessing substantial growth, with a forecast value of $1.2 billion in 2024 and a CAGR of 9.2% expected from 2026 to 2033, potentially reaching $2.5 billion by 2033. This surge is driven by a growing community of both enterprises and hobbyists who are embracing CNC technology for smaller-scale production and prototyping. As the technology becomes more accessible and affordable, it is poised to revolutionize DIY manufacturing and innovation, further shaping the future of the manufacturing landscape.

Unlocking Precision: CNC Milling Machines Efficiency Trends

This chart illustrates the increasing efficiency of CNC milling machines from 2019 to 2023, indicating a positive trend in modern manufacturing due to advancements in technology and processes.

Related Posts

-

Exploring the Versatility and Innovations of CNC Machines in Modern Manufacturing

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

What is the Future of CNC Machine 3D Printer Technology

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering