METROM’s

Blog

METROM’s

Blog

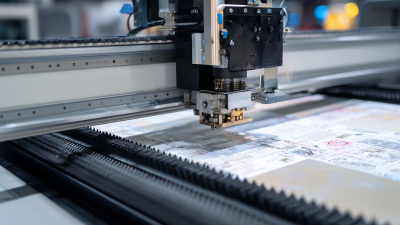

Exploring the Versatility and Innovations of CNC Machines in Modern Manufacturing

In recent years, the manufacturing landscape has undergone a significant transformation driven by advancements in technology, particularly in the realm of CNC (Computer Numerical Control) machines. These innovative tools have revolutionized production processes across various industries, enhancing precision, efficiency, and flexibility in operations. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.52 billion by 2026, growing at a CAGR of 6.4% from 2021. This growth is fueled by the increasing demand for automation in manufacturing, as businesses seek to optimize their production capabilities and reduce operational costs. About CNC machines—capable of producing complex shapes with high precision—they allow for greater customization and shorter lead times, ultimately driving competitiveness and innovation in modern manufacturing. This versatility also enables manufacturers to adapt quickly to changing market demands, making CNC technology an indispensable asset in today’s industrial practices.

Understanding CNC Machines: A Fundamental Shift in Production Methods

Computer Numerical Control (CNC) machines represent a significant advancement in production methods, transforming traditional manufacturing processes into highly efficient operations. At the core of this transformation is the integration of sophisticated software and hardware that allow for precise control of machine tools. Among the various components vital to maximizing the efficiency of CNC machines, post processors play a crucial role. Post processors translate the toolpath data generated by CAD/CAM software into machine-specific code, ensuring that CNC machines can interpret and execute the intended operations accurately.

Furthermore, modern innovations such as energy-saving strategies and the deceleration of spindle operations during no-load periods are changing the landscape of CNC machining. These strategies not only enhance the operational efficiency of machine tools but also contribute to sustainable manufacturing practices. By incorporating methods such as Failure Modes, Effects, and Criticality Analysis (FMECA), manufacturers can further improve the reliability of CNC systems, minimizing downtimes and optimizing performance. As such, the evolution of CNC machines signifies a fundamental shift in production methods, perpetually pushing the boundaries of what is possible in manufacturing.

The Evolution of CNC Technology: From Manual to Automated Precision

CNC technology has come a long way since its inception, transforming the manufacturing landscape from traditional manual techniques to advanced automated systems. This evolution has immensely enhanced precision and efficiency, with CNC machines now capable of performing complex operations with minimal human intervention. A report from a leading industry analyst highlights that incorporating CNC technology can boost production speed by up to 50%, reducing material waste and ensuring higher quality outputs.

As industries embrace these advancements, there's a pressing concern regarding the skilled labor force. The rise of automated processes like laser welding has led to a redefining of skilled labor, as companies deal with a notable shortage of qualified welders. According to recent industry data, around 40% of manufacturing firms report difficulties in finding skilled workers, prompting a shift in training and workforce development strategies.

**Tips:** To ensure the effective adoption of CNC technology, organizations should invest in employee training programs that focus on both technical skills and innovative practices. Additionally, establishing partnerships with technical schools can help bridge the skills gap, ensuring a steady influx of proficient workers familiar with modern manufacturing technologies.

Exploring the Versatility and Innovations of CNC Machines in Modern Manufacturing - The Evolution of CNC Technology: From Manual to Automated Precision

| Dimension | Manual CNC Technology | Automated CNC Technology | Innovations |

|---|---|---|---|

| Precision Level | ±0.01 mm | ±0.001 mm | Higher precision through advanced algorithms |

| Setup Time | Several hours | Minutes | Quick-change tooling systems |

| Programming Method | G-code | CAD/CAM integration | Visual programming interfaces |

| Operator Skill Level | Highly skilled | Moderate skill required | Automated error correction |

| Production Volume | Low to Medium | High | Mass production capabilities |

| Material Compatibility | Limited | Extensive | Adaptive machining technologies |

Applications of CNC Machines Across Diverse Industries: A Game Changer

CNC machines have emerged as game changers across various industries, significantly altering how products are designed and manufactured.

In the realm of medical research, for instance, recent innovations in desktop CNC solutions are making it possible for researchers to achieve industrial-grade precision right at their workstations.

This democratization of CNC technology allows smaller labs and independent researchers to create customized components, streamlining the development of medical devices and improving overall efficiency.

CNC machines have emerged as game changers across various industries, significantly altering how products are designed and manufactured.

In the realm of medical research, for instance, recent innovations in desktop CNC solutions are making it possible for researchers to achieve industrial-grade precision right at their workstations.

This democratization of CNC technology allows smaller labs and independent researchers to create customized components, streamlining the development of medical devices and improving overall efficiency.

Moreover, the adaptability of CNC machining is evident in its application to advanced materials like carbon fiber and titanium. Industries demanding lightweight yet durable structures are finding CNC machining indispensable for creating high-performance components. As these machines continue to evolve, incorporating automation and enhanced measurement systems, manufacturers can increase production rates while maintaining accuracy and reducing costs. This technological revolution underscores the critical role of CNC machines in modern manufacturing, driving innovation across sectors ranging from medical to aerospace.

Innovative Features of Modern CNC Machines: Enhancing Efficiency and Versatility

Modern CNC machines are redefining the landscape of manufacturing with their innovative features that significantly enhance efficiency and versatility. Reports indicate that the global CNC machine market is projected to reach $117 billion by 2026, growing at a CAGR of 6.8% from 2021 to 2026. This growth is driven by the increasing demand for precision manufacturing and automation in various industries, including aerospace, automotive, and medical devices. Advanced CNC machines now integrate features such as multi-axis machining, which allows manufacturers to create complex parts in a single setup, reducing production time and minimizing errors.

Additionally, the implementation of IoT (Internet of Things) in CNC technology has revolutionized real-time monitoring and predictive maintenance. According to a study by Deloitte, manufacturers that adopt smart manufacturing practices, including CNC automation, can see productivity increases of up to 30%. These innovative machines are equipped with sensors and connectivity features that enable continuous performance tracking, leading to optimization of machining processes and reducing downtime. The enhanced adaptability of modern CNC machines not only streamlines operations but also allows businesses to quickly respond to changing market demands, highlighting the imperative role of technology in contemporary manufacturing.

Challenges and Future Prospects of CNC Machining in Global Manufacturing

As CNC machining continues to revolutionize the manufacturing landscape, it faces several challenges that need to be addressed to ensure its long-term sustainability. One major concern is the skill gap in the workforce. According to a report by the National Association of Manufacturers, 2.4 million manufacturing jobs are expected to go unfilled by 2028 due to a lack of skilled workers. This underscores the importance of investing in education and training programs to prepare the next generation for careers in CNC machining.

Moreover, the integration of advanced technologies such as artificial intelligence and IoT into CNC machines presents both opportunities and hurdles. While these innovations can enhance efficiency and precision, they also require significant capital investments and pose challenges in terms of cybersecurity. According to a study by the Aberdeen Group, 79% of manufacturers have experienced a breach in the past two years, highlighting the urgent need for solid cybersecurity measures.

Tips: To tackle these challenges, companies can implement mentorship programs within their organizations to help bridge the skills gap and foster a culture of continuous learning. Additionally, investing in cybersecurity training for employees can mitigate the risks associated with intelligent manufacturing systems, ensuring that these innovations can be utilized safely and effectively.

Related Posts

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

Exploring the Best CNC Machines and Their Alternatives for Your Business Needs

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

How to Optimize Efficiency with CNC Industrial Machines for Your Business

-

7 Best CNC Machine Innovations Transforming Manufacturing in 2023