METROM’s

Blog

METROM’s

Blog

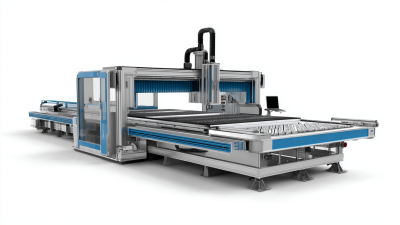

The Ultimate Guide to CNC Machine Tools Understanding Trends Technologies and Market Dynamics

In the rapidly evolving landscape of manufacturing, CNC machine tools have emerged as a cornerstone technology, facilitating precision and efficiency in production processes. According to a recent report by MarketsandMarkets, the global CNC machine tools market is projected to reach USD 100 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is driven by increasing automation, the demand for high-quality products, and the integration of technologies such as IoT and AI into manufacturing systems. As manufacturers adapt to changing market dynamics and technological advancements, understanding the trends and innovations surrounding CNC machine tools is crucial. This guide will explore the key developments, technologies, and market dynamics influencing this essential sector, providing insights for industry professionals seeking to stay at the forefront of CNC machining advancements.

Key CNC Technologies Revolutionizing Manufacturing Today

In today’s rapidly evolving manufacturing landscape, CNC (Computer Numerical Control) technologies are at the forefront of transformation, reshaping how industries approach precision and automation. One key technology revolutionizing manufacturing is adaptive machining, which utilizes real-time data to adjust machining parameters on the fly. This innovation allows for increased efficiency and reduced material waste, ultimately leading to a more sustainable manufacturing process. By consistently monitoring machine performance and workpiece conditions, manufacturers can achieve higher precision and faster turnaround times, meeting the demands of modern production.

Another significant advancement is the integration of artificial intelligence (AI) into CNC systems. AI-driven algorithms enhance machine learning capabilities, allowing CNC machines to optimize their operations continuously. This means that over time, machines become smarter, learning from past jobs to execute future tasks more efficiently. Moreover, the advent of cloud computing enables seamless data sharing and connectivity across various machines and facilities, driving a shift towards smart manufacturing ecosystems. As these technologies advance, they provide manufacturers with the tools necessary to stay competitive in an increasingly digital world, ensuring that they can adapt to market changes with agility and precision.

Essential Trends Shaping the Future of CNC Machine Tools

As the CNC machine tools industry evolves, several essential trends are significantly shaping its future. One of the most prominent trends is the integration of automation and robotics. This advancement allows for increased productivity and efficiency, as machines can operate with minimal human intervention. The adoption of collaborative robots, or cobots, alongside CNC machines is enhancing operational flexibility, enabling manufacturers to optimize their workflows and maximize output.

Another key trend is the rise of smart manufacturing powered by the Internet of Things (IoT). CNC machines equipped with IoT sensors can collect and analyze data in real-time, leading to better decision-making and predictive maintenance strategies. This connectivity paves the way for data-driven insights that help manufacturers reduce downtime and improve the overall quality of their products. Additionally, the growing demand for customization and smaller production runs is pushing CNC manufacturers to implement agile and scalable solutions, ensuring they can respond quickly to market needs.

Furthermore, sustainability is becoming increasingly important in the CNC machine tools market. Manufacturers are now focusing on energy-efficient machines and environmentally friendly materials. This shift not only meets regulatory requirements but also caters to the growing consumer demand for sustainable practices. As companies look to reduce their carbon footprints, CNC machine tools that prioritize sustainability will likely gain a competitive edge in the evolving landscape of manufacturing.

The Ultimate Guide to CNC Machine Tools - Essential Trends Shaping the Future of CNC Machine Tools

| Trend | Description | Impact on Market | Future Outlook |

|---|---|---|---|

| Automation | Increased use of automated processes to enhance efficiency. | Higher productivity and reduced labor costs. | Continued growth in automated systems. |

| Industry 4.0 | Integration of Internet of Things (IoT) in manufacturing processes. | Real-time data analysis and improved decision making. | Expansion of smart factories. |

| Additive Manufacturing | Use of 3D printing technology in production. | Reduced material waste and faster prototyping. | More applications across various industries. |

| Sustainability | Focus on environmentally friendly manufacturing practices. | Improved brand image and compliance with regulations. | Greater emphasis on eco-friendly technologies. |

| Skills Gap | Shortage of skilled labor in CNC machining. | Potential delays in production and innovation. | Increased investment in training and education. |

Navigating the CNC Market: Insights for Buyers and Investors

Navigating the CNC market can be a daunting task for buyers and investors due to its rapidly evolving nature and diverse offerings. As new technologies emerge and trends shift, it's essential to stay informed about the latest developments in CNC machine tools. For prospective buyers, understanding the specific requirements for their applications, whether in metalworking, woodworking, or composite machining, is crucial.

**Tip:** Research the latest technologies such as advanced software algorithms and automation features that can enhance productivity. Investing in machinery that not only meets current needs but also has scalability options for future demands is key.

Investors should focus on market dynamics such as demand fluctuations and the competitive landscape, as these factors significantly impact profitability. Identifying companies that prioritize innovation and sustainability can guide informed investment decisions.

**Tip:** Keep an eye on industry reports and news to anticipate market trends, as companies adapting to customer feedback and evolving technology are more likely to succeed in a competitive environment.

Understanding CNC Applications Across Various Industries

The global CNC machine tools market is witnessing significant growth, driven by the increasing demand across various industries. By 2032, it is projected that the market size will expand from $136.3 billion in 2025 to an impressive $229.46 billion, reflecting a compound annual growth rate (CAGR) of 8.1%. This growth is indicative of the rising applications of CNC technology in sectors such as aerospace, automotive, and healthcare, where precision machining is critical.

In parallel, the global metal cutting tools market is also on an upward trajectory, expected to grow from $86.24 billion in 2025 to $141.65 billion by 2032 at a CAGR of 7.3%. As manufacturers strive to optimize their processes and reduce costs, effective tool management becomes increasingly vital. The challenges include soaring costs associated with various SKUs and the necessity for specialized machining and tooling application expertise, emphasizing the need for robust solutions and partnerships within the industry to navigate this evolving landscape effectively.

The Ultimate Guide to CNC Machine Tools: Understanding Applications Across Industries

Maximizing Efficiency: Best Practices for CNC Machining Operations

In the world of CNC machining, maximizing efficiency is crucial for maintaining competitiveness and profitability. Implementing best practices can streamline operations and enhance productivity. One effective approach is to invest in regular maintenance of CNC machines. By ensuring that machines are well-maintained, operators can reduce downtime and extend the lifespan of their equipment. Consistent upkeep can also prevent minor issues from turning into significant disruptions.

Another key practice is optimizing tool paths. Analyzing and refining tool paths can drastically reduce cycle times and improve finish quality. CNC operators can utilize advanced software to simulate machining processes and find the most efficient routes. This not only conserves time but also minimizes wear on tools, leading to cost savings.

Lastly, enhancing team training is vital in promoting efficient operations. Regular training sessions can ensure that all operators are up-to-date with the latest technologies and techniques in CNC machining. Empowered with the right knowledge, workers can utilize machines to their full potential and troubleshoot issues as they arise. These strategies collectively contribute to a more efficient CNC machining operation, ultimately driving better results and profitability.

Related Posts

-

Exploring the Best CNC Machines and Their Alternatives for Your Business Needs

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

-

Top Strategies for Choosing the Best CNC Machine Tools for Your Business

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering