METROM’s

Blog

METROM’s

Blog

How to Choose the Right Manufacturing Machines for Your Production Needs

In today’s rapidly evolving industrial landscape, selecting the right manufacturing machines is crucial for optimizing production efficiency and maintaining competitiveness. According to a report by Markets and Markets, the global manufacturing equipment market is expected to reach $2.4 trillion by 2026, highlighting the substantial investment opportunities within the sector. Advanced manufacturing machines, ranging from CNC machines to additive manufacturing technologies, play a vital role in enhancing productivity and reducing operational costs. As industries increasingly adopt automation and smart manufacturing practices, understanding the specific needs of your production process becomes imperative. This blog will guide you through the key considerations when choosing manufacturing machines, ensuring that you make informed decisions that align with your operational goals and deliver sustainable gains.

Identifying Your Production Goals and Requirements

When selecting the right manufacturing machines for your production needs, it’s vital to first identify your production goals and requirements. This exercise allows businesses to align their machinery capabilities with both operational efficiency and sustainability objectives. In the current landscape, many organizations are driven by the Sustainable Development Goals (SDGs), which emphasize the importance of environmentally friendly practices. For instance, companies are increasingly aiming for net zero emissions by 2050, as highlighted by recent analyses from reputable energy agencies.

Additionally, understanding your production goals requires a thorough assessment of your specific operational needs. For example, optimizing crop production while adhering to climate management strategies reflects a dual challenge. A report suggests that natural climate solutions (NCS) can yield benefits for both climate change mitigation and agricultural output. However, the actual effectiveness of these solutions remains largely untested. Thus, in the decision-making process for manufacturing equipment, it is essential to consider how each machine can contribute not only to immediate production efficiency but also to long-term sustainability and climate goals. By doing this, businesses can ensure they are not only meeting current demands but also contributing positively to global challenges.

Evaluating the Types of Manufacturing Machines Available

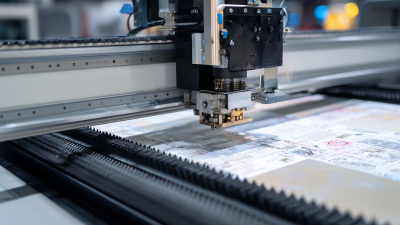

When evaluating the types of manufacturing machines available, it’s crucial to first understand your production needs. Different manufacturing processes require specific types of machinery to optimize efficiency and output. For instance, if your production involves repetitive tasks, automated machines such as CNC (Computer Numerical Control) machines may be ideal. These machines enhance precision and speed, making them well-suited for high-volume production runs.

Alternatively, for processes requiring flexibility and adaptability, modular machines that can be easily reconfigured are beneficial. These types of machines allow manufacturers to switch between different products without significant downtime, making them valuable for businesses with diverse product lines. Additionally, consider the integration of technology in modern machines. Machines equipped with IoT (Internet of Things) capabilities can provide real-time data, allowing manufacturers to monitor performance and reduce operational costs. By assessing your specific production requirements alongside the advantages of different machine types, you can make informed decisions that will best support your manufacturing goals.

Assessing the Cost-Effectiveness of Different Machine Options

When selecting manufacturing machines, assessing cost-effectiveness is crucial to ensuring a successful production process. The first step in this assessment is to evaluate the upfront costs associated with each machine option. This includes not only the purchase price but also installation costs, training for operators, and any necessary modifications to existing facilities. Understanding these initial investments helps build a clearer picture of the financial commitment required.

Next, it's important to analyze the operational costs over the machine's lifespan. This includes energy consumption, maintenance expenses, and potential downtime costs. A machine that is cheaper upfront may incur higher operating costs or require frequent repairs, impacting overall profitability. Additionally, consider the machine's efficiency and productivity rates. Machines that produce higher output with lower waste can significantly contribute to long-term cost savings. By carefully weighing these factors, manufacturers can make informed decisions that align with their production goals and budgetary constraints.

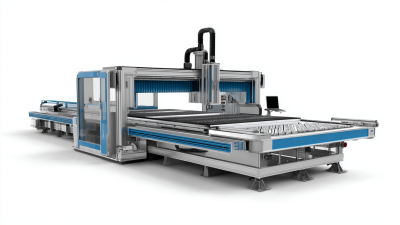

Considering Space and Layout Requirements for Machinery

When selecting manufacturing machines, it’s crucial to consider space and layout requirements to optimize production efficiency. According to a report by the International Society of Automation, approximately 30% of manufacturing space is often underutilized, which can lead to increased operational costs and reduced workflow efficiency. Understanding the dimensions of your machinery and how they fit into the existing layout allows you to maximize production capacity while minimizing waste.

Furthermore, the arrangement of machinery can significantly impact safety and accessibility. A recent study from the National Institute of Standards and Technology found that poor layout design can lead to increased accident rates by up to 40%. By strategically planning the layout with safety in mind, manufacturers can streamline processes while ensuring a safer workplace for employees. Utilizing tools such as 3D layout modeling can help visualize the optimal positioning of machines, helping to create a balanced workflow that enhances productivity and reduces the risk of hazards.

Production Machinery Space Utilization

Finding Reliable Suppliers and Support for Your Equipment Choices

When selecting manufacturing machines, finding reliable suppliers is paramount to ensuring operational efficiency and minimizing downtime. According to a report by Deloitte, companies that prioritize supplier relationships are 3.5 times more likely to be high-performing organizations. This statistic underscores the importance of choosing suppliers who not only provide quality equipment but also offer robust support and maintenance services. By partnering with reputable suppliers, manufacturers can gain access to advanced technologies and responsive customer service, which can significantly enhance production capabilities.

Moreover, it's crucial to evaluate the total cost of ownership when sourcing equipment. A study by PwC indicates that maintenance and support can account for up to 30% of total equipment costs over its lifespan. Therefore, investing in machinery from suppliers known for good after-sales service can lead to long-term savings and improved productivity. Additionally, a supplier's track record in providing timely support can reduce the risks associated with equipment failures, further solidifying the importance of selecting trustworthy partners to support manufacturing operations.

How to Choose the Right Manufacturing Machines for Your Production Needs

| Machine Type | Key Features | Production Capacity (units/hour) | Energy Consumption (kWh) | Price Range ($) | Supplier Reliability Rating (1-5) |

|---|---|---|---|---|---|

| CNC Machine | Precision cutting, programmable | 20 | 5 | 15,000 - 30,000 | 4.5 |

| Injection Molding Machine | High precision, fast cycle time | 15 | 8 | 25,000 - 50,000 | 4.2 |

| Laser Cutting Machine | High accuracy, versatile material use | 25 | 6 | 20,000 - 40,000 | 4.8 |

| 3D Printer | Rapid prototyping, customizable | 10 | 2 | 5,000 - 15,000 | 4.6 |

Related Posts

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

5 Incredible Reasons Why 5 Axis Milling Machines Are Revolutionizing Manufacturing Efficiency

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

Unmatched Precision and Innovation Chinese Manufacturing Leads the Way in High Precision Milling Machines

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing