METROM’s

Blog

METROM’s

Blog

How to Choose the Right Axis CNC Machine for Your Business Needs

Choosing the right axis CNC machine for your business needs is a crucial decision that can significantly impact your production efficiency and overall profitability. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, highlighting the increasing demand for precision and automation in various industries. As businesses strive to enhance their manufacturing capabilities, understanding the different configurations of axis CNC machines—such as 3-axis, 4-axis, and 5-axis systems—is vital. These machines offer varying degrees of flexibility and precision, catering to different machining requirements. Research from Statista indicates that companies utilizing advanced CNC technology can reduce production time by up to 30%, demonstrating the importance of selecting the right machine tailored to specific operational needs. Thus, investing in the appropriate axis CNC machine is not just a matter of cost but also a strategic choice that can propel a business towards sustained growth and competitive advantage.

Identifying Your Business Requirements for CNC Machining

Choosing the right CNC machine for your business starts with a deep understanding of your specific requirements. Factors such as production volume, material types, and complexity of parts play a crucial role in determining which machine suits your operational needs best. According to recent industry reports, businesses utilizing advanced CNC technologies have reported efficiency gains of up to 30%, highlighting the importance of matching machine capabilities with production goals. Additionally, considering the rapid advancements in machine monitoring software can further enhance operational reliability and feedback mechanisms, ensuring that your chosen machinery aligns with evolving market demands.

As companies face ever-changing economic conditions, a robust manufacturing strategy becomes essential. Engaging in localized business support initiatives can drive growth, as seen in companies participating in industrial growth programs that aim to expand operations while tackling key challenges. Reports suggest that businesses that incorporate Industry 4.0 principles in their manufacturing processes experience significant spikes in productivity and adaptability, which are vital attributes when selecting CNC machinery. Identifying these critical aspects of your business not only aids in the selection of the appropriate CNC machine but also positions you to navigate future challenges effectively.

Understanding Different Types of Axis CNC Machines

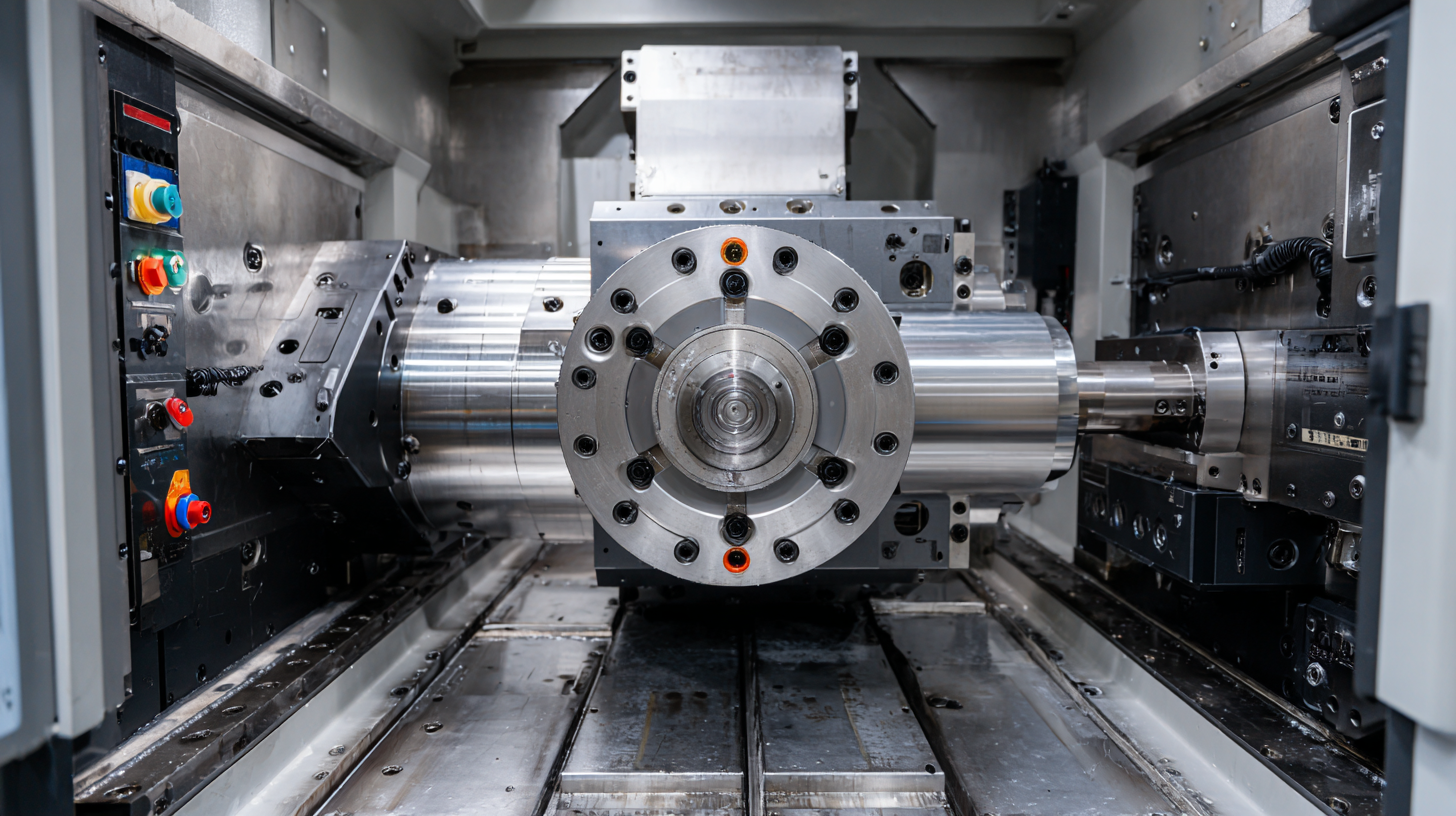

When selecting a CNC machine for your business, understanding the different types of axis configurations is crucial. The most common types include

3-axis,

4-axis, and

5-axis machines. A

3-axis CNC machine is typically used for simpler applications, making it ideal for flat parts and basic milling tasks.

According to a recent market report by ResearchAndMarkets,

3-axis CNC machines account for approximately 50% of the CNC machining market, indicating their popularity in small-scale manufacturing.

On the other hand, 4-axis and 5-axis CNC machines offer more versatility for complex shapes and continuous operations.

The 4-axis machines allow for the ability to rotate on one additional axis, ideal for jobs such as engraving or large-scale component production.

Ahead of expected industry growth, it’s projected that the market for 5-axis CNC machines will reach USD 3 billion by 2025, as they enable precision work on intricate designs from various angles.

Tips: When choosing an axis CNC machine, assess the complexity of your projects and production volume. For intricate designs or projects that require multiple sides to be machined, investing in a

5-axis machine might be beneficial. Additionally, consider the type of materials you will be working with, as some machines are better suited for specific materials than others.

Evaluating CNC Machine Features and Specifications

When evaluating CNC machine features and specifications, it's essential to consider the specific needs of your business. Start by assessing the types of materials you will be working with, as different Axis CNC machines have varying capabilities in handling materials such as metal, wood, or plastic. Additionally, the machine's precision and tolerance levels are crucial—higher precision models can significantly enhance the quality of your finished products, particularly in industries where accuracy is paramount.

Another important factor is the size and complexity of the projects you'll be undertaking. Ensure that the machine has adequate working dimensions to accommodate your largest parts. Look into the machine's speed and feed rates as well, since higher speeds can improve productivity, but should not come at the expense of quality. Furthermore, consider the control system and software compatibility; a user-friendly interface can streamline operations and reduce training time for your staff, ultimately affecting your bottom line. By methodically analyzing these features, you can make an informed decision that aligns with your business goals.

How to Choose the Right Axis CNC Machine for Your Business Needs - Evaluating CNC Machine Features and Specifications

| Feature | Description | Importance | Recommended Value |

|---|---|---|---|

| Axis Configuration | Number of axes available for machining. | Critical for part complexity. | 3, 4, or 5 axes depending on needs. |

| Spindle Speed | Maximum speed the spindle can reach. | Affects material compatibility and machining time. | 5000 - 20000 RPM. |

| Table Size | Dimensions of the machine table. | Important for workpiece size capability. | 1200mm x 600mm or larger. |

| Accuracy | Tolerance range of the machine. | Key for precision parts. | ±0.01mm or better. |

| Control System | Type of software/hardware for operation. | Affects ease of use and capabilities. | Fanuc, Siemens, or equivalent. |

| Weight | Total machine weight. | Influences stability and vibration. | Above 2000kg for industrial use. |

Assessing Cost vs. Value for Your Business Investment

When considering the investment in an Axis CNC machine, it is crucial to assess the cost versus value for your business. While the initial purchase price can be enticing, focusing solely on cost can lead to overlooking the long-term benefits that a high-quality machine can offer. Evaluating the total cost of ownership, which includes maintenance, energy consumption, and operational efficiency, will provide a clearer picture of the machine's value over time.

When considering the investment in an Axis CNC machine, it is crucial to assess the cost versus value for your business. While the initial purchase price can be enticing, focusing solely on cost can lead to overlooking the long-term benefits that a high-quality machine can offer. Evaluating the total cost of ownership, which includes maintenance, energy consumption, and operational efficiency, will provide a clearer picture of the machine's value over time.

Tips for evaluating value include looking at the machine's specifications and capabilities to ensure it aligns with your production needs. Additionally, considering the manufacturer's reputation and the available customer support can significantly impact your experience. Investing in a machine with robust after-sales service can mitigate downtime and enhance productivity in the long run.

Furthermore, think about scalability and future needs. A slightly higher upfront investment in a versatile CNC machine that can handle a wider range of projects may save you from the necessity of future upgrades. By prioritizing long-term value over short-term savings, you create a solid foundation for your business’s growth and success.

Considering Future Growth and Technology Upgrades for CNC Machines

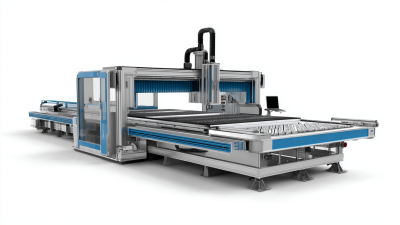

When selecting the right axis CNC machine for your business, it is crucial to consider not only your current needs but also potential future growth and technology upgrades. The

CNC machine market is projected to grow to

432.5 billion yuan by 2024, reflecting a compound annual growth rate of

5.75% over the previous years. Businesses must anticipate how their projects may expand and evolve, investing in machines that can adapt and incorporate new technologies.

Five-axis CNC machines, for instance, are at the forefront of high-end manufacturing and can accommodate complex parts with greater precision. As industries incorporate

digital transformation and automation, the ability to upgrade machinery through software enhancements or hardware modifications becomes essential. By choosing machines that support technological advancements, businesses can maximize operational efficiency and stay competitive in an increasingly demanding market. It is imperative to analyze both immediate requirements and long-term scalability when making your investment in

CNC technology.

Related Posts

-

The Ultimate Guide to CNC Machine Tools Understanding Trends Technologies and Market Dynamics

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

Crafting Excellence in CNC Machining for Global Manufacturing Solutions

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets