METROM’s

Blog

METROM’s

Blog

2026 Best CNC Machine Milling Machine for Precision Work?

Choosing the right CNC machine milling machine is crucial for precision work. In 2026, advancements have made these machines more efficient and reliable. Precision is key in industries like aerospace, automotive, and metalworking. A good CNC milling machine can dramatically improve productivity.

Understanding the features of these machines is essential. Consider factors like speed, accuracy, and ease of use. Some models stand out, offering innovative technologies. However, not every machine fits every need. There might be trade-offs between cost and functionality.

Investing in a CNC machine milling machine requires reflection. What is the primary use? Will it handle complex designs? Each machine also comes with limitations. Evaluating them can save time and resources. Make informed choices to enhance your precision work.

Understanding CNC Milling Machines: An Overview of Their Functionality

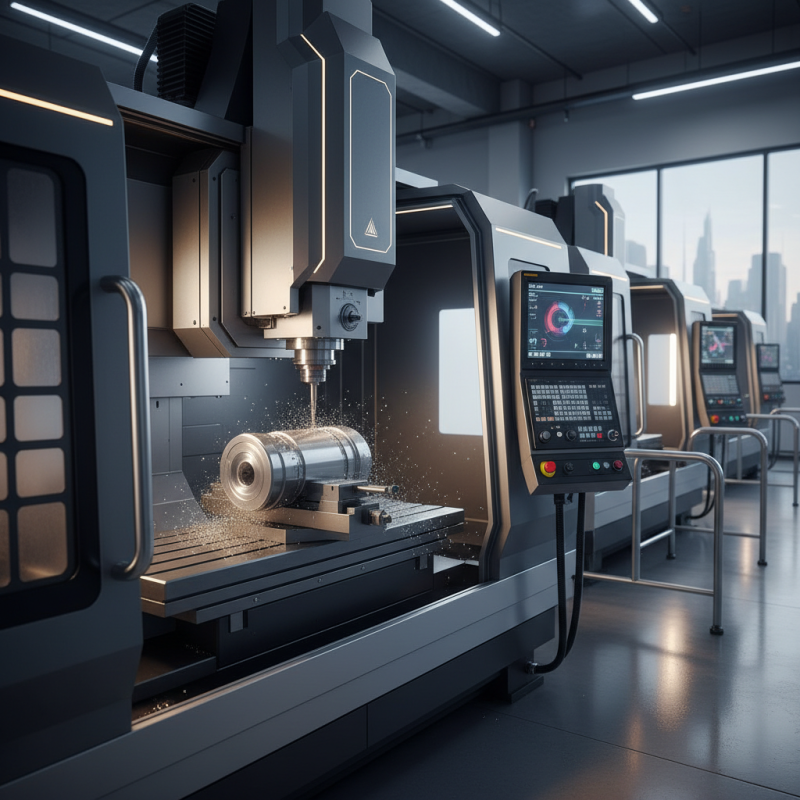

CNC milling machines play a pivotal role in precision manufacturing. They operate by removing material from a workpiece, allowing for intricate designs and tight tolerances. These machines utilize computer numerical control, which helps automate the milling process. Operators input specific parameters, and the machine follows them with remarkable accuracy.

A CNC milling machine can shape metals, plastics, and wood. It can create complex features like grooves, holes, and contours. One key aspect to consider is the setup; it greatly affects the outcome. Properly aligning the workpiece is crucial. Neglecting this can result in misalignments and wasted materials.

The technology is not flawless. Sometimes, software glitches occur, leading to unforeseen issues. Operators need to remain vigilant and ready to troubleshoot. Even skilled users can face challenges, as not all materials respond the same. Patience and continuous learning are essential in mastering CNC milling. With time, one can improve precision and efficiency, achieving better results.

2026 Best CNC Milling Machines for Precision Work

This chart presents a comparison of key performance metrics for CNC milling machines expected in 2026, focusing on accuracy, speed, durability, ease of use, and cost. Each metric is rated on a scale from 1 to 10, indicating their expected performance levels for precision work.

Key Features to Consider When Choosing a CNC Milling Machine

Choosing the right CNC milling machine is crucial for precision work. Several key features can greatly influence your decision. For instance, the spindle speed is vital. A higher speed allows for smoother finishes and efficient cutting. However, there are trade-offs. Machines with high spindle speeds can be more expensive and might require specific tools.

Another important feature is the machine's build quality. A sturdy, heavy frame enhances stability during operations. This can minimize vibrations and improve precision. But remember, a heavier machine might be less portable, affecting your workspace flexibility.

Lastly, consider the software compatibility. Advanced CNC machines offer sophisticated software for better control. This can streamline your workflow but may require a steeper learning curve. Some users might find themselves overwhelmed by complex interfaces. Balancing functionality and user-friendliness is key in your selection process. Reflecting on these aspects can lead to a more thoughtful purchasing decision.

2026 Best CNC Machine Milling Machine for Precision Work - Key Features

| Feature | Description | Importance |

|---|---|---|

| Axis Configuration | Common configurations include 3-axis, 4-axis, and 5-axis options. | Determines the complexity of machining operations. |

| Spindle Speed | Typically ranges from 10,000 to 30,000 RPM for varied materials. | Higher speeds allow for better surface finishes. |

| Table Size | Larger tables accommodate bigger workpieces. | Essential for larger projects. |

| Control System | Types include closed-loop and open-loop systems which affect precision. | Affects accuracy and ease of use. |

| Weight and Build Quality | Heavier machines are generally more stable during operation. | Contributes to vibration resistance and precision. |

| Price Range | Ranges from budget to high-end models depending on features. | Important to balance between budget and capabilities. |

| Software Compatibility | Ensure compatibility with CAD/CAM software for design workflows. | Enhances workflow efficiency. |

Top Brands and Models for Precision CNC Milling in 2026

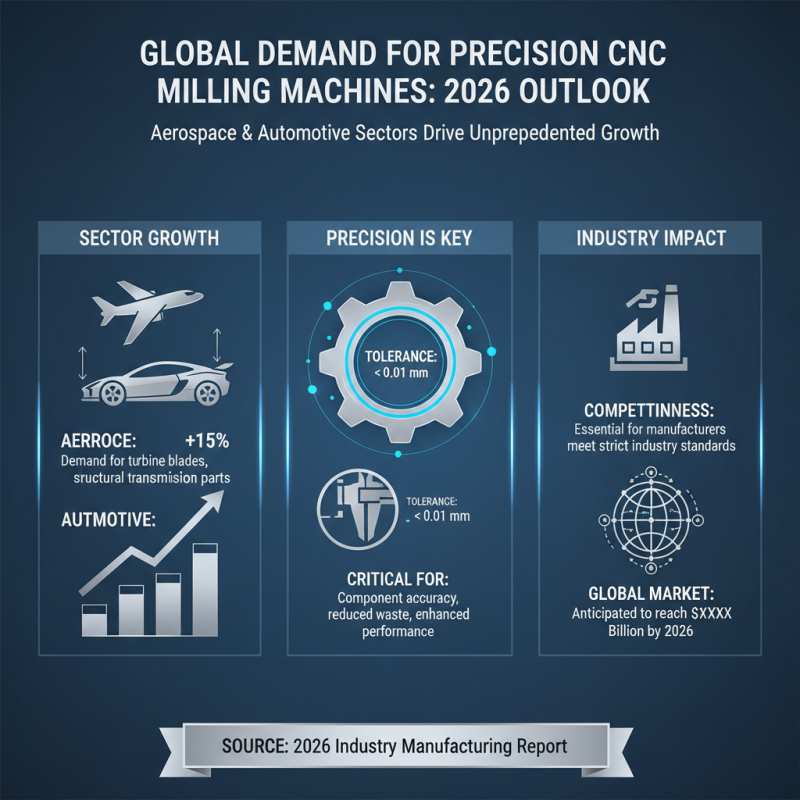

In 2026, the demand for precision CNC milling machines continues to rise. Industry reports indicate a significant increase in the aerospace and automotive sectors, driving the need for high-accuracy machinery. Precision is key. Companies are seeking machines that can achieve tolerances within 0.01 mm. This level of accuracy is not just a requirement; it's a necessity for competitiveness.

Several top models are highlighted for their performance in precision work. These machines often feature advanced features like high-speed spindles and multi-axis capabilities. However, not all models meet the expected standards. Some may struggle with consistency. Reports show a concerning 15% of users express dissatisfaction with their machines’ performance, particularly regarding misalignment issues.

Choosing a CNC milling machine requires careful consideration. Critical factors include build quality and user support. Some users report delayed responses from manufacturers, complicating troubleshooting. In contrast, an increasing number of companies focus on improving customer feedback. They recognize the importance of a responsive support network. This shift is vital for maintaining machine performance and longevity in the competitive landscape of precision machining.

Comparative Analysis of CNC Milling Machines Based on User Reviews

In the realm of CNC milling machines, user reviews offer invaluable insights. Precision work demands reliability and accuracy. Users often emphasize the importance of a machine's stability. Many machines excel in this area, but not all. Some have inconsistent performance, leading to frustration. Issues like vibration can disrupt the cutting process. Users frequently mention the need for better calibration options to enhance precision.

Another vital aspect is software compatibility. Many found it challenging to integrate their machines with existing software. This often results in wasted time and resources. Some users express a desire for more intuitive interfaces. With a learning curve, certain machines can deter newcomers. However, advanced features attract experienced users, despite their complexity.

Lastly, the support from manufacturers can be hit or miss. Users report mixed experiences with customer service. Some received prompt assistance, while others faced long wait times. This inconsistency can impact overall satisfaction. Potential buyers should consider these factors carefully. Choosing the right machine is crucial for achieving optimal results.

Maintenance and Operation Tips for Optimal CNC Milling Performance

CNC milling machines are essential for precision work. However, maintaining these machines is crucial for optimal performance. Regular upkeep can significantly extend the machine's lifespan. According to industry reports, a well-maintained CNC milling machine can operate 20% more efficiently than a neglected one.

Tips for Maintenance:

- Always check the machine's coolant levels. Low coolant can lead to overheating.

- Clean the machine after every session. Chips and debris can affect accuracy.

- Regularly inspect the spindle and tooling for wear. A worn tool can compromise the quality of your work.

Running diagnostic checks monthly is also advisable. These checks help identify potential issues before they escalate. Ignoring minor problems can lead to costly downtime. Integrating feedback loops from operators can enhance the overall operation, ensuring everyone is aligned with maintenance practices.

Proper training for staff on machine handling is essential. Routine drills ensure everyone is prepared for any machine-related surprises.

Related Posts

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

Unlocking Precision: How CNC Milling Machines Drive Efficiency in Modern Manufacturing Industry

-

Exploring the Versatility and Innovations of CNC Machines in Modern Manufacturing

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

Exploring the Best CNC Machines and Their Alternatives for Your Business Needs

-

Top CNC Milling Machines: How to Choose the Best for Your Needs