METROM’s

Blog

METROM’s

Blog

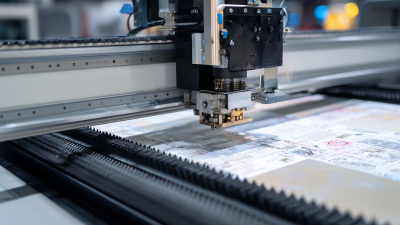

7 Best CNC Machine Innovations Transforming Manufacturing in 2023

In the ever-evolving landscape of manufacturing, innovation is key to staying competitive and efficient. As we delve into 2023, the realm of CNC machines has witnessed remarkable advancements that are reshaping production processes across various industries. This blog will explore the seven best CNC machine innovations that are transforming manufacturing today. From enhanced automation and precision to breakthroughs in materials and software, these innovations are not just about CNC machines; they represent a shift towards smarter, more adaptable manufacturing solutions.

Join us as we uncover how these cutting-edge technologies are setting new benchmarks for efficiency, quality, and flexibility in the manufacturing sector.

Revolutionary Materials in CNC Machining for Enhanced Durability

As we progress into 2023, the landscape of CNC machining is being reshaped by innovative materials that promise enhanced durability and performance. One standout advancement is the use of metal composites fabricated through selective laser melting (SLM). This additive manufacturing technique empowers engineers to create intricate designs that were previously impossible with traditional machining methods. The result is a new generation of products that boast not only superior strength but also reduced weight, making them ideal for a wide range of applications from aerospace to automotive.

When incorporating these materials into CNC machining processes, consider several tips to maximize their potential. First, ensure that your machining parameters are finely tuned for the specific composite material being used, as each has unique characteristics affecting tool selection and cutting speeds. Additionally, invest in advanced post-processing techniques, as they can significantly improve the surface finish and performance of the finished product.

Moreover, keeping abreast of the latest research and advancements in the field is crucial. Collaborating with material scientists and engaging in continuous education can give manufacturers a competitive edge. By embracing these revolutionary materials and techniques, businesses can enhance their manufacturing capabilities and meet the growing demands of the marketplace.

Smart CNC Machines: Integrating AI for Precision and Efficiency

In 2023, the manufacturing landscape is witnessing a paradigm shift with the integration of artificial intelligence (AI) in CNC (Computer Numerical Control) machines. Smart CNC machines are not just a trend; they are becoming essential for enhancing precision and operational efficiency. According to a recent report by MarketsandMarkets, the global market for smart manufacturing is expected to reach $510.3 billion by 2025, driven by advancements in AI technologies. This evolution allows manufacturers to optimize machining processes, reduce waste, and enhance product quality through real-time data analysis and adaptive learning systems.

One of the most significant benefits of AI integration in CNC machines is predictive maintenance. For instance, a study by McKinsey revealed that predictive maintenance could reduce machine downtime by up to 50%, translating to substantial cost savings. Furthermore, smart CNC machines equipped with AI algorithms can analyze production data to predict tool wear and adjust parameters automatically, ensuring consistent output quality. As the manufacturing sector embraces these innovations, companies can expect improved efficiency and a competitive edge, setting a new standard for productivity and precision in the era of Industry 4.0.

Additive Manufacturing: Merging CNC Techniques with 3D Printing

In 2023, the fusion of additive manufacturing with traditional CNC techniques has marked a significant shift in the landscape of modern manufacturing. By leveraging the strengths of both methodologies, companies are producing parts that are not only more complex but also more efficient. Additive manufacturing allows for the creation of intricate designs that may have been impossible or too costly to achieve with conventional CNC methods. This synergy enables manufacturers to optimize material usage and reduce waste, thereby promoting sustainability in production processes.

Furthermore, the integration of 3D printing with CNC machining leads to enhanced customization capabilities. Businesses can quickly iterate on designs and produce small batches of unique components without significant time or cost penalties. This is particularly beneficial in industries such as aerospace and automotive, where precision and tailored solutions are paramount. As manufacturers continue to explore the benefits of this hybrid approach, we can expect to see a rapid evolution in design possibilities, speed of production, and a new era of efficiency in manufacturing practices.

7 Best CNC Machine Innovations Transforming Manufacturing in 2023

| Innovation | Description | Impact on Manufacturing | Key Benefits |

|---|---|---|---|

| Hybrid CNC Machines | Combine CNC machining with additive manufacturing for versatile production. | Increases flexibility in manufacturing processes. | Cost efficiency, reduced waste, enhanced material compatibility. |

| AI-Driven CNC Optimization | Utilizes artificial intelligence to optimize machining parameters. | Improves machining speed and reduces cycle times. | Enhanced efficiency, decreased operational costs. |

| Integrated IoT Systems | Connects machines to the internet for real-time monitoring and control. | Facilitates predictive maintenance and reduces downtime. | Improved machine longevity, reduced maintenance costs. |

| Flexible Manufacturing Systems (FMS) | Automated systems that adjust to variable production needs. | Enhances production agility and responsiveness. | Higher throughput, better resource utilization. |

| Smart Workholding Solutions | Innovative clamping systems that enhance part stability. | Improves accuracy and quality of machined components. | Reduced setup times, improved precision. |

| Augmented Reality (AR) in CNC Training | Utilizes AR for enhanced training of CNC operators. | Accelerates the learning curve and improves safety. | More effective training, reduced errors. |

| Sustainable Manufacturing Practices | Emphasizes eco-friendly materials and processes. | Reduces environmental impact of manufacturing. | Better compliance with regulations, improved brand image. |

Real-Time Monitoring: The Future of CNC Operations and Maintenance

In 2023, real-time monitoring has emerged as a game-changer in the realm of CNC operations and maintenance. With the rise of Industry 4.0, manufacturers are increasingly leveraging IoT technology to collect and analyze machine data instantaneously. According to a recent report by the Association for Manufacturing Technology, companies that implement real-time monitoring experience an average of 20% reduction in downtime and a 15% increase in overall equipment effectiveness (OEE). This shift allows operators to anticipate maintenance needs before they lead to costly breakdowns, ensuring a smoother production process.

Tip: To implement real-time monitoring effectively, invest in sensors that provide accurate data on machine performance. Integrating these sensors with a robust data analytics platform will help you visualize trends and predict failures, ultimately saving both time and resources.

Additionally, real-time monitoring facilitates a proactive approach to CNC machining. With data insights available at their fingertips, operators can make informed decisions and optimize machining parameters on the fly. According to a Deloitte report, businesses that adapt to such advanced monitoring systems are 30% more likely to meet production targets consistently. This capability not only boosts productivity but also enhances product quality, ensuring customer satisfaction.

Tip: Regularly update your monitoring system's software to integrate new features and improve data interpretation. Staying current with technology will allow you to maximize efficiency and maintain a competitive edge in the market.

Real-Time Monitoring in CNC Operations (2023)

Sustainability in CNC: Eco-Friendly Innovations Driving Change

Sustainability has become a cornerstone of modern manufacturing, and CNC machining is no exception. As industries face the urgent need to reduce their carbon footprints and minimize waste, innovations in CNC technology are leading the way towards eco-friendly practices. Advanced software systems now allow for more precise cutting strategies, reducing material waste and energy consumption. This precision not only enhances the quality of the products but also makes a significant impact on the environment.

Moreover, manufacturers are increasingly adopting biodegradable and recyclable materials in the CNC machining process. These materials not only meet stringent regulatory standards but also appeal to a growing consumer base that prioritizes sustainability. Additionally, the integration of renewable energy sources, such as solar or wind, into CNC machining operations is gaining traction, further decreasing overall emissions. As these eco-friendly innovations continue to evolve, they exemplify a shift towards responsible manufacturing that balances productivity with environmental stewardship.

Related Posts

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

Exploring Tomorrow's Innovations in Home CNC Machines

-

Top Global Manufacturers of Best CNC Cutting Machines for Your Sourcing Needs