METROM’s

Blog

METROM’s

Blog

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

In the rapidly evolving landscape of additive manufacturing, the emergence of the CNC machine 3D printer has significantly reshaped the industry, offering unparalleled precision and versatility. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach $62.79 billion by 2026, accelerating innovation across various sectors, including aerospace, healthcare, and automotive. Among these advancements, the integration of CNC capabilities with 3D printing technology stands out, enabling manufacturers to create complex geometries with high accuracy and repeatability. This hybrid approach not only enhances production efficiency but also expands the possibilities for design freedom, making the CNC machine 3D printer a pivotal player in today's competitive global markets. As we delve into the intricate details of what distinguishes the best CNC machine 3D printers, we will explore their technical specifications and practical applications that set them apart in this dynamic field.

Key Features of Leading CNC Machine 3D Printers in Competitive Markets

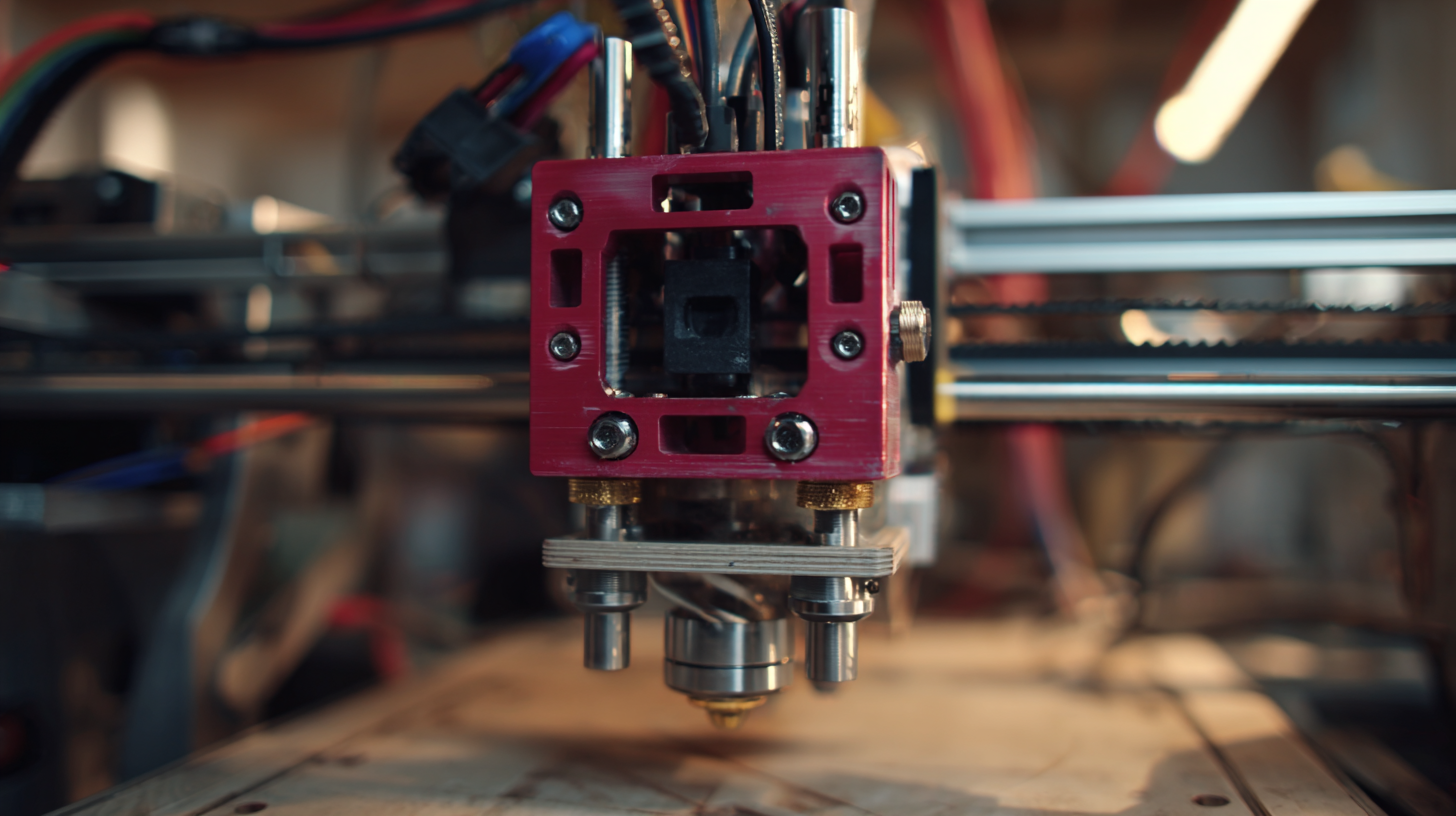

When considering what sets leading CNC machine 3D printers apart in competitive global markets, several key features come into play. Precision engineering is paramount; top-tier printers utilize advanced motion control systems that ensure exact replication of intricate designs. This level of accuracy not only enhances the quality of the finished product but also increases efficiency in production, allowing manufacturers to meet strict client specifications without compromising on speed.

Another significant factor is the versatility of materials these printers can handle. The best CNC machine 3D printers are compatible with a wide range of filaments, including plastics, composites, and metals, enabling them to serve diverse industries from aerospace to healthcare. Moreover, enhancements in user interface design and software integration have streamlined operations, making these machines more accessible to a broader range of users. By incorporating intuitive controls and advanced slicing software, they facilitate a more user-friendly experience, ensuring that both novice and experienced operators can achieve optimal results effortlessly.

Innovative Technologies Driving CNC Machine 3D Printer Development

The rapid advancement of technology has transformed the landscape of CNC machine 3D printers, making innovation a critical driver for success in the global market. One of the most significant developments is the integration of artificial intelligence and machine learning algorithms into CNC systems. These technologies optimize the printing process by predicting potential failures and adjusting parameters in real-time, enhancing precision and reducing material waste. As manufacturers strive for efficiency, AI-driven solutions offer a competitive edge, ensuring that the best CNC machine 3D printers stand out in an increasingly crowded marketplace.

Furthermore, the use of advanced materials is reshaping product capabilities. Innovations in composite materials and high-strength polymers allow for the creation of more durable and lightweight parts, appealing to industries such as aerospace and automotive. By incorporating these cutting-edge materials into their designs, CNC machine 3D printers not only meet the rigorous demands of professional users but also expand their functionalities. As these technologies continue to evolve, they pave the way for new applications, positioning top-tier CNC 3D printers as essential tools for modern manufacturing.

Innovative Technologies Driving CNC Machine 3D Printer Development

Comparative Analysis: Global Standards in CNC Machine 3D Printing

When evaluating what makes a CNC machine 3D printer stand out in global markets, a comparative analysis of global standards is essential. According to a recent report by the Wohlers Associates, the additive manufacturing sector, which includes CNC-based 3D printing, is projected to grow from $12.6 billion in 2022 to over $35 billion by 2027. This exponential growth highlights the increasing demand for high-quality, precision-driven 3D printing solutions that meet international standards.

One key aspect that sets top CNC 3D printers apart is their ability to achieve dimensional accuracy and repeatability. The ISO 2768 standard, which pertains to general tolerances, is a benchmark that leading manufacturers adhere to, ensuring product consistency and quality. Furthermore, the incorporation of advanced materials such as carbon fiber and metal alloys is transforming the capabilities of CNC 3D printers, allowing for stronger yet lightweight designs that appeal to diverse industries, from aerospace to automotive.

Tip: When selecting a CNC machine 3D printer, assess its material compatibility to ensure it can work with a range of innovative materials.

Another critical factor is the integration of user-friendly software solutions that streamline the design-to-production workflow. According to a survey conducted by the additive manufacturing community, companies leveraging sophisticated software for CAD/CAM processes reported a 30% increase in productivity.

Tip: Invest in a machine with robust software support that includes simulation capabilities to visualize and optimize production processes before execution.

Market Trends and Consumer Preferences for CNC Machine 3D Printers

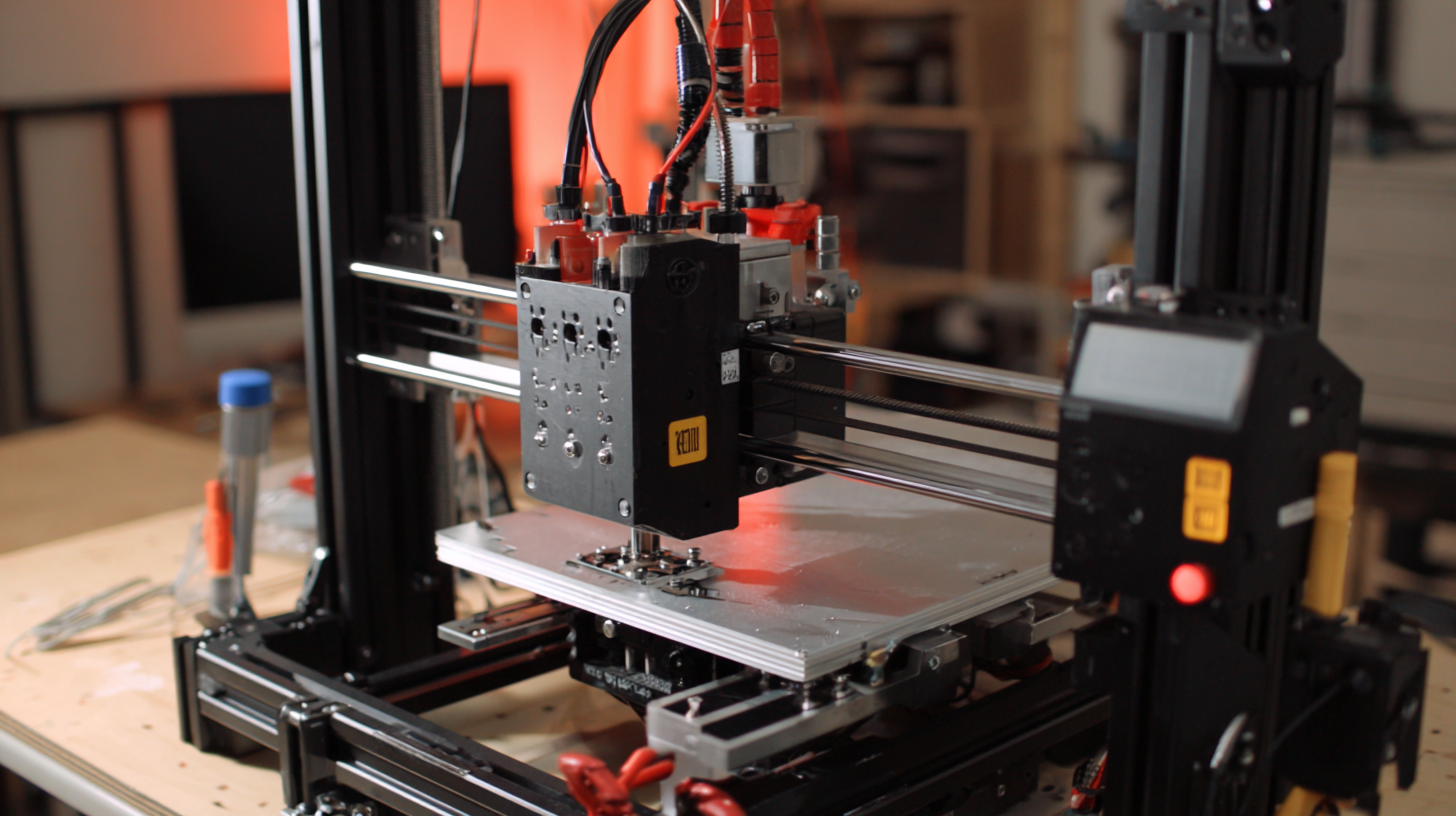

The market for CNC machine 3D printers is rapidly evolving, driven by technological advancements and changing consumer preferences. One of the key trends is the increasing demand for versatile machines that can handle a variety of materials. Users are no longer satisfied with printers that are limited to only plastics; they seek the capability to work with metals, ceramics, and composite materials, allowing for more complex and functional designs. This shift is pushing manufacturers to innovate and develop hybrid models that integrate both additive and subtractive processes.

Moreover, consumers are placing a higher value on ease of use and integration within existing manufacturing workflows. As industries look to adopt smart manufacturing practices, the need for CNC machines that can seamlessly connect with design software and other machinery is paramount. Additionally, there is a growing focus on sustainability, with users preferring machines that not only minimize waste but also use eco-friendly materials. This convergence of trends highlights the importance of adaptability and user-centric features in distinguishing the best CNC machine 3D printers in a competitive global marketplace.

Challenges and Opportunities in the CNC Machine 3D Printing Industry

In the rapidly evolving landscape of the CNC machine 3D printing industry, both challenges and opportunities abound. One significant challenge lies in integrating advanced technologies such as machine learning (ML) and explainable artificial intelligence (XAI) into additive manufacturing processes. As experts in the field indicate, the application of AI can dramatically enhance production efficiency and innovation, yet the complexity of these technologies often poses a barrier to widespread adoption. The ability to interpret and trust AI-driven insights will be crucial for manufacturers looking to leverage these advancements effectively.

On the other hand, the opportunities presented by emerging methodologies in 3D printing are vast. Recent developments, such as 3D printing techniques that redefine culinary experiences and bridge manufacturing capabilities, show the potential for innovation across diverse sectors. Moreover, the emphasis on sustainability in industries like aerospace and automotive highlights the role of additive manufacturing in achieving ambitious environmental goals. As companies continue to navigate these dual dimensions of challenge and possibility, the landscape of CNC machine 3D printing will undoubtedly transform, setting the stage for groundbreaking advancements and new market dynamics.

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

| Feature | Importance Level | Market Demand | Challenges |

|---|---|---|---|

| Precision | High | Increasing | Technical limitations |

| Speed | Medium | Stable | Balancing speed and quality |

| Material Compatibility | High | Growing | Material costs |

| Ease of Use | Medium | High | User training |

| Cost Efficiency | High | Stable | Pricing pressures |