METROM’s

Blog

METROM’s

Blog

What is a 5 Axis Milling Machine and How It Revolutionizes Precision Engineering

The advent of the 5 axis milling machine has marked a significant turning point in the realm of precision engineering, offering capabilities that were previously unattainable with traditional milling methods. According to a report by Markets and Markets, the global market for advanced machining technologies, including 5 axis milling, is projected to reach $90.59 billion by 2026, growing at a CAGR of 6.3%.

This growth is driven by industries requiring intricate designs, such as aerospace and automotive sectors, where precision is paramount. The 5 axis milling machine allows for the simultaneous movement across multiple axes, thereby reducing the need for multiple setups and enhancing accuracy. This technological innovation not only streamlines production processes but also leads to improved surface finishes and reduced lead times, ultimately revolutionizing how engineers approach complex manufacturing challenges.

Understanding the Basics of 5 Axis Milling Machines

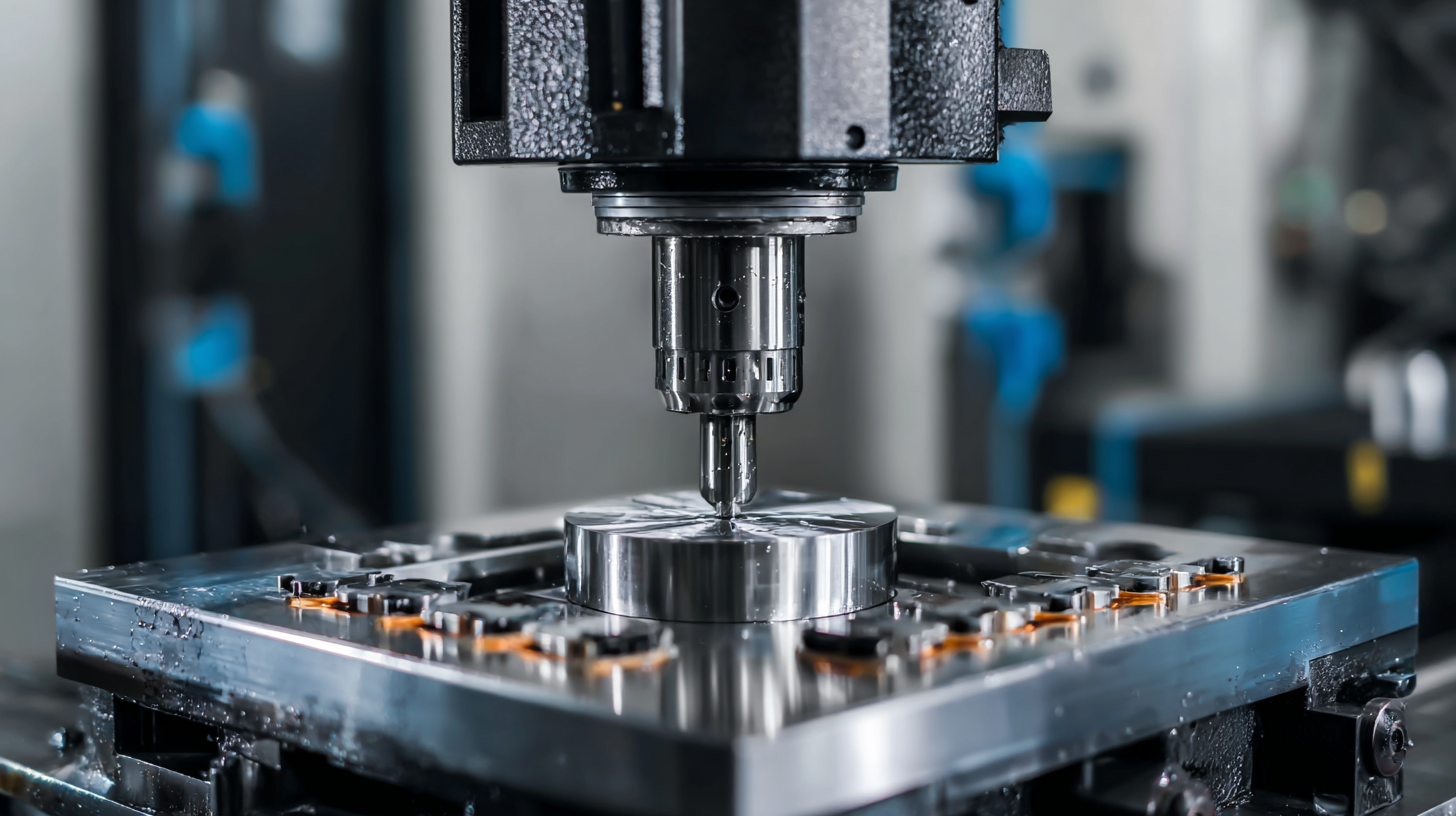

A 5-axis milling machine is an advanced machining tool that enhances precision engineering by allowing the cutting tool to move along five axes simultaneously. This capability enables manufacturers to create complex geometries and intricate designs that would be difficult or impossible to achieve with traditional 3-axis machines. Understanding the basics involves recognizing how these machines operate: they have the ability to tilt the workpiece and rotate the cutting tool, which facilitates machining on multiple surfaces in a single setup.

A 5-axis milling machine is an advanced machining tool that enhances precision engineering by allowing the cutting tool to move along five axes simultaneously. This capability enables manufacturers to create complex geometries and intricate designs that would be difficult or impossible to achieve with traditional 3-axis machines. Understanding the basics involves recognizing how these machines operate: they have the ability to tilt the workpiece and rotate the cutting tool, which facilitates machining on multiple surfaces in a single setup.

The advantage of 5-axis milling is not just in its versatility, but also in the efficiencies it brings to the production process. By minimizing the need for repositioning the workpiece, manufacturers can reduce setup times and improve accuracy. This technology is particularly valuable in industries such as aerospace and medical device manufacturing, where precision and detail are paramount. As engineers become more familiar with the operational principles of 5-axis machines, they can leverage this technology to push the boundaries of what is possible in precision engineering.

Key Benefits of Using 5 Axis Technology in Precision Engineering

The adoption of 5-axis milling technology significantly enhances precision engineering by allowing for unparalleled flexibility in tool movement. Unlike traditional 3-axis machines that can only move along the X, Y, and Z axes, 5-axis machines can pivot and rotate on two additional axes. This multidimensional capability enables manufacturers to produce complex geometries and intricate designs with a high degree of accuracy, reducing the need for multiple setups and minimizing the potential for human error.

Another key benefit of 5-axis technology is the ability to work on all sides of a part without repositioning it. This streamlined process not only saves time but also increases productivity. Components can be machined in a single setup, which ensures tighter tolerance and better surface finishes. Additionally, manufacturers can utilize a wider range of cutting tools, allowing for more efficient material removal and improved overall machining performance. In an era where precision and efficiency are paramount, 5-axis milling machines are revolutionizing the field of precision engineering, offering both quality and cost-effectiveness.

Applications of 5 Axis Milling in Various Industries

The advancements in 5-axis milling technology have dramatically transformed various industries, particularly in precision engineering applications. This capability allows for intricate machining processes, enabling manufacturers to create complex geometries with superior accuracy.

Industries such as aerospace, automotive, and medical benefit significantly from this technology, as it reduces the need for multiple setups and enhances production efficiency. For example, the global dental milling machine market is projected to grow from $984.9 million in 2025 to $1.865 billion by 2032, with a compound annual growth rate of 9.5%. This growth is largely driven by the increasing demand for sophisticated dental solutions, which rely on advanced milling processes.

Moreover, in the aerospace sector, 5-axis milling facilitates the production of lightweight components that adhere to stringent performance specifications. The ability to work on complex parts in a single setup minimizes errors associated with repositioning, thereby improving yield and reducing waste. Similarly, in the automotive industry, manufacturers leverage this technology to develop components that enhance vehicle performance while being cost-effective. As 5-axis milling continues to evolve, its applications will expand, further revolutionizing manufacturing processes across diverse sectors.

Comparison of 5 Axis Milling Machines with Traditional Milling Methods

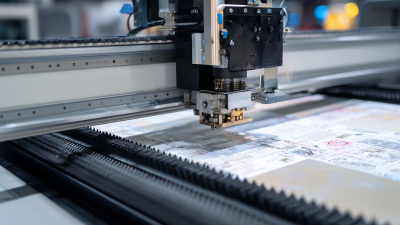

5 axis milling machines are at the forefront of modern manufacturing, offering unparalleled precision and versatility compared to traditional milling methods. Unlike conventional milling, which typically operates on three axes, 5 axis machining can manipulate the workpiece on five different axes simultaneously. This capability allows for the creation of complex geometries and intricate designs that would be incredibly difficult or impossible to achieve with traditional machines. The increased flexibility not only enhances efficiency but also reduces the need for multiple setups, thereby minimizing potential errors in the production process.

When comparing 5 axis milling machines to their traditional counterparts, it's essential to consider the benefits of time and cost savings. Traditional methods often require extensive manual adjustments and multiple machine setups, which can lead to longer production times and increased labor costs. In contrast, 5 axis machines streamline the workflow, allowing for rapid production cycles without compromising on quality.

**Tips:** When considering a transition to 5 axis milling machines, evaluate your specific production needs and the types of materials you work with. Investing in proper training for your team can also maximize the benefits of this advanced technology. Additionally, regular maintenance of the machines can ensure a longer lifespan and optimal performance, helping you maintain precision in your engineering projects.

What is a 5 Axis Milling Machine and How It Revolutionizes Precision Engineering

| Feature | 5 Axis Milling Machine | Traditional Milling Machine |

|---|---|---|

| Movement Axes | 5 Axes (X, Y, Z, A, B) | 3 Axes (X, Y, Z) |

| Complexity of Parts | High Complexity | Low to Medium Complexity |

| Setup Time | Low | High |

| Precision | High Precision | Moderate Precision |

| Cost | Higher Initial Investment | Lower Initial Investment |

| Material Versatility | Wide Range | Limited Range |

Tips for Maximizing Efficiency and Precision with 5 Axis Milling

5-axis milling machines are at the forefront of precision engineering, offering unparalleled capabilities in machining complex geometries. These advanced machines allow for simultaneous movement across five different axes, which significantly reduces the need for repositioning workpieces and minimizes setup times. According to a report by Market Research Future, the global CNC machining market is expected to reach $100 billion by 2025, reflecting the increasing reliance on technologies that enhance precision and efficiency.

To maximize efficiency and precision with a 5-axis milling machine, operators should employ several best practices. First, regular maintenance of the machine is crucial to ensure optimal performance. Keeping the cutting tools sharpened and using the right tool path strategies can significantly extend tool life and reduce wear. Additionally, implementing advanced software for tool path optimization can minimize machining time, ultimately leading to increased throughput without sacrificing quality.

Moreover, it's essential to invest in employee training. Understanding the intricacies of 5-axis machining, including fixture setup and the effective use of simulation software, can lead to substantial gains in productivity. Reports indicate that machines operated by well-trained staff can improve output by as much as 30%, highlighting the importance of expertise in leveraging the full capabilities of these sophisticated machines.

Related Posts

-

Exploring Tomorrow's Innovations in Home CNC Machines

-

Mastering Precision in Milling Machines A Comprehensive Guide for Global Buyers

-

Exploring Innovative Examples of High Precision Milling Machines in Modern Manufacturing

-

How to Optimize CNC Machine Milling Efficiency: Insights from Industry Data

-

Exploring Unique Features of Industrial 3D Printing Machines and Their Ideal Applications

-

5 Essential Tips for Choosing the Best CNC Machine Printing for Your Business